46~80 item / All 80 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF46~80 item / All 80 items

● The equipment is old, and spare parts are difficult to obtain. ● Since the machines are made overseas, obtaining maintenance parts is troublesome. For those who have such concerns! Our company offers overhaul and retrofitting services for gear grinding machines, shaving cutter grinding machines, screw grinding machines, and cylindrical grinding machines, as well as support for NC conversion and domestic sourcing of electrical components, enabling effective utilization of your existing equipment. * Please feel free to contact us regarding the feasibility of equipment repairs. * In the PDF materials, we introduce examples of our overhaul and retrofitting projects!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The theme is "Challenge to Maximum Precision and Extreme Productivity." The maximum spindle speed of the hob is 9,000 min-1, and the maximum workpiece rotation is 1,500 min-1, which is among the fastest levels in the country. 【Features】 ■ By adopting a horizontal design, it is less affected by thermal displacement. ■ The horizontal design also makes it easy to accommodate gantry loaders. ■ Skyving machining is possible (automatic phase alignment device option). ■ The adoption of NC control for the tailstock and push torque control enables easy setup and accommodates various workpiece shapes. ■ By minimizing the protrusion of the hob head, vibration resistance and high rigidity are achieved.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

□ I want to reduce machining processing troubles. □ I want to reduce quality-related defects. Is the issue with dimensions a machine problem? □ Issues like burrs and steps do not go away even after taking measures. □ Is the current processing method appropriate? □ Am I creating programs based on incorrect judgments? □ Are the tools and conditions appropriate? I want to extend the tool life. □ It is difficult to determine the timing for regrinding. □ What is the correct way to use chucks and holders? □ I want to deepen my knowledge of cutting processing. □ I want to know efficient processing methods. □ I want to eliminate the skill gap between new and young employees and veterans. □ I want to shorten the program creation time. Sometimes I can't meet deadlines. Etc. If any of these apply to you, please feel free to consult with us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Aren't there fewer opportunities to "challenge something" that creates "new technologies" or "values"? We will create a CAM program and simulate the effects of reducing processing time and steps. We will compile the current improvement points and comparison results into a report for explanation. Please feel free to contact us for more details.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

< How to Proceed with CAM Simulation > - There are two models: one for "plastic molds" and one for "die-casting molds." - Please choose one and create an actual CAM program. - We will compare processing time and processes with our CAM program. - We will summarize the current improvement points and comparison results in a report for your review. We will send the 3D model after receiving your request. For more details, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We have adopted a structure that attaches a handle to the bar coater, improving the "Select-Roller" to achieve stable coating, and we propose a more precise and smooth coating environment. *The bar of the Select-Roller L60 can be used as is, and simply replacing the handle will enhance the coating environment. Unlike typical wire bars, this bar has a solid shape without any wire winding. It is also suitable for color matching of gravure inks and checking coating thickness. This next-generation "wireless bar coater" improves common issues found with wire bars, such as <breaking, loosening, and clogging>. 【Differences from Wire Bars】 ■ No disconnection due to the integrated design ■ No loosening due to the integrated design ■ Less prone to clogging ■ Good cleanability

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The OSG System Products' bar coater is a wireless bar coater with a monolithic shape that does not have a wire wrapped around it. The S-Bar is standardized in pocket capacity every 10% due to its precision mold manufactured with high accuracy. By unifying the distance between grooves (pitch: P) to 0.2mm, it standardizes the groove shape and takes into account issues related to the coating environment that depend on the shape. The pocket capacity of the bar coater is manufactured with a tolerance of ±3%, and an inspection report is also attached. Other features not found in wire bars include: - Reduced clogging - Excellent cleanability - Superior leveling properties (less prone to streaking) Custom manufacturing is available to match your desired diameter and length. It is also possible to manufacture in a shape compatible with our products, Select-Roller (L60, L250, Takumi).

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The OSG System Products wireless bar coater 'Select-Roller & A-Bar' is a bar coater with an integrated shape that does not use wire. As a result, there is no clogging between wires, making it easy to clean, and it also excels in the leveling of the coating liquid. We offer a lineup of standard stock items including the conventional manual A-Bar and the Select-Roller with a handle. The Select-Roller reduces variations in coating thickness by relying solely on the weight of the bar and handle without applying pressure. Please experience it through our free rental of demo units. The usual rental period is two weeks, but extensions are possible, so feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

OSG-WIKUS band saws offer a wide range of options, allowing you to choose the "optimal band saw" tailored to your processing environment. We have everything from "standard band saws" to "top-of-the-line band saws," and by making the right selection, we support the maximization of productivity. 【Product Lineup and Features】 ■ Carbide + Coating 【FUTURA PREMIUM】 Ideal for those seeking processing efficiency ■ Carbide 【DUROSET】 A versatile model with carbide specifications □ High-speed Steel + Coating 【PROFLEX PREMIUM】 Ideal for long life when cutting H-beams □ High-speed Steel 【VARIO】 A versatile model perfect for various processing needs - best-selling product We also offer optimal blade shapes and materials for various workpieces. 【Do you have any of these concerns?】 - I want to extend the life of my band saw - Blade chipping is occurring - I want to reduce processing time "Leave it to OSG-WIKUS" to solve your problems. Maximize productivity with the optimal band saw! For more details, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A wide set (wide clam) that prevents narrowing is equipped with an excellent cutting edge profile. Therefore, it provides a clean cutting surface. Additionally, the profile blade shape excels in chipping resistance, making it suitable for single cuts of H steel as well as multi-cuts like bundled cuts. The cutting edge uses cobalt high-speed steel equivalent to SKH59, and is further enhanced with a PREMIUM coating, achieving a cutting edge hardness of 3800HV. This results in excellent wear resistance and a long lifespan. For more details, please download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In materials such as catalogs and brochures, it is quite difficult to pinpoint the information you really want to know. Therefore, we provide the information you want interactively, so you can easily reach what you need! On top of that, it's safe, secure, and quick. That's the concept.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

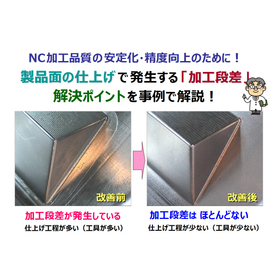

In finishing processes, if there are many leftover steps and a large number of tools are used, thermal displacement of each axis and the main spindle of the machine can easily cause "machining steps" on the finished surface. Therefore, to reduce or eliminate machining steps, it is essential to minimize the types and number of tools used during the finishing process. 【Five Important Points in Finishing Processes】 ◇ Tool Selection 1. Use tools with good cutting performance and edge accuracy (no variation in R accuracy or outer diameter). 2. Use tools with low deflection and high rigidity (use a pencil neck when the protrusion is long). 3. Use tools with coatings suitable for the work material (especially for soft steel). ◇ Machining Methods and Cutting Conditions 1. Ensure that roughing before finishing does not leave any material in corners or recesses. 2. In semi-finishing, process the entire area to a uniform finishing allowance (do not leave large bumps). 3. In finishing, avoid high-speed rotation to minimize the expansion and contraction of the machine spindle. 4. Use cutting fluid to improve chip removal and lubrication of the cutting edge. For more details, please refer to the PDF document. If you have any questions, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

To improve the accuracy of NC machining, controlling "tool deflection" is essential. However, issues such as tool engagement occurring at the vertical walls, corners, and recesses of rib grooves (see image) can lead to machining troubles. To achieve direct engraving without causing these problems, there are three important points to consider: 1. During roughing of rib groove shapes, keep the deflection of the cutting edge below the finishing allowance. 2. To reduce the deflection of the cutting edge, minimize the cutting resistance acting on it. 3. Increase tool rigidity within permissible limits concerning the height of the machining shape and the slope angle of the vertical walls. Therefore, to perform stable cutting operations with small-diameter tools of Φ4 or less, selecting "sturdy" tools, such as pencil neck tools, becomes particularly important. For more details, please refer to the PDF document. If you have any questions, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The left image shows a case where "gouging" occurred on a ribbed wall shape, which is an example of a machining problem. The cause was that "the tool tip bent significantly due to cutting resistance" during rough machining. In contour path machining, when entering a solid ribbed shape, the tool tip experiences the greatest cutting resistance. However, if the groove width is narrow, the tool tip may bend and gouge into the wall. The amount of tool deflection varies significantly not only with the magnitude of cutting resistance but also with the tool's overhang length. If the overhang length doubles, the deflection increases by a factor of eight, proportional to the cube. Additionally, the deflection amount also changes with the tool diameter. It is inversely proportional to the fourth power, so the deflection of a tool with a diameter of Φ8 is about 2.4 times that of a tool with a diameter of Φ10 (assuming the same overhang length). Therefore, when machining with small diameter tools (Φ4 or less), using pencil neck tools and considering "rigidity in tool selection" is particularly important for stable cutting operations. For more details, please refer to the PDF document. If you have any questions, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The standard angle is 45°, but since we produce the molds for groove formation in-house, we can custom-make them from 0° to 90°. The "E-Roll (small diameter gravure roll)" utilizes the mold technology that our company has developed over many years, allowing for smooth groove formation. The end attachment shapes can also be produced to match machine specifications. As a special response, we can also perform processing such as "grooving." We also offer new surface treatments to enhance coating leveling characteristics. 【Features】 ■ Selectable serration as needed ■ Variations - Thin film: Can be produced up to L400 line - Thick film: Can be produced up to L14 line - Fine adjustment: Thickness adjustment possible with a wide variety of specifications, etc. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

As a solution to various challenges in coating/applying, how about DLC coating for coating/application bars, gravure rolls, blades, and film transport guide rolls? **Features and Benefits of DLC Coating** - Capable of processing long items, with a maximum diameter of Φ300 mm and a maximum length of 3000 mm. - Surface hardness of HV1500 to 2000, excellent wear resistance for extended lifespan. - Low friction coefficient of 0.2 or less, suppressing the occurrence of substrate scratches and improving cleanability. - Can also add an anti-static function to prevent static electricity buildup. - Capable of altering surface energy (contact angle of pure water ranges from 20° to 80°). - High oxidation initiation temperature and excellent corrosion resistance, suitable for use in acidic environments. **Also for Rubber Rolls!** DLC treatment is also possible for rubber rolls. However, please note that the color will be black; if black is not acceptable, we can also recommend a special treatment that does not change the color. Feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

If the head of the screw is small and low, the screw recess (drive part) also naturally needs to be smaller and shallower. Microsticks is a groundbreaking screw system that answers that demand. It is available in sizes starting from 0.6mm. It accommodates not only low-head screws but also the head shapes of standard screws, and it functions effectively as a tamper-proof screw. 【Features】 ■ No cam-out ■ No thrust required ■ High workability ■ High torque ■ Ultra-precise bits ■ Tamper-proof ■ Long-lasting bits ■ Reliable screw bit fitting *For more details, please contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

LH sticks pursue the rationality of screw fastening, and are broadly classified into LH type, where the torque transmission part is located on the outer circumference of the screw head, and LR type, where it is on the inside. Depending on compatibility with fastening tools, they are composed of a tapered type (LR, LH) with grip and a straight type (LH-S, LR-S) without grip. Furthermore, they are systematized with the ultra-line hole (ULR), which mainly focuses on micro screws, and Rockstar, which applies ULR (mainly for construction screws). 【Features】 ■ Excellent torque transmission capability ■ No cam-out ■ Improves workability, safety, and reliability of screw fastening ■ Useful for both production design and disassembly design ■ Optimal for ISO 14000 series (environmental laws) *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

QuaStix is a completely new 4-slot recess characterized by its "non-cam-out" feature and excellent torque transmission capability, allowing it to be opened and tightened with a conventional cross screwdriver even in the absence of specialized tools. This modern fastening system achieves a level of workability, safety, and reliability in screw fastening that was not possible with traditional cross recesses. 【Features】 ■ Non-cam-out ■ Good torque transmission rate ■ Excellent bit adhesion ■ Superior bit durability ■ Usable with commercially available cross bits *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"OSG BITS" achieves a high-density and reinforced metallic fiber structure on the surface through a unique forging method developed by OSG. As a result, we provide OSG BITS with uniform quality and high workability in terms of hardness, torsional strength, and dimensional accuracy. We also offer quick and flexible responses. You can trust us with special items and small lots. 【Features】 ■ Stability ■ Fitting ■ Excellent splitting accuracy ■ Optimally managed heat treatment ■ Cutting-edge material selection ■ Long lifespan ■ Strong clamping support ■ Excellent resistance to fracture *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The OSG Group's Sanwa Seiki offers options for BMI's "Vacuum Heat Treatment Furnace" according to the type of furnace. In addition to standard heat treatment, it is also capable of performing "special treatments" such as low-pressure carburizing and low-pressure nitriding. 【Options List】 All of BMI's high-temperature furnaces can be equipped with low-pressure carburizing (ALLCARB) as an option. The low-pressure vacuum furnace (tempering furnace) B5_R series offers an option for low-pressure nitriding. It uses a reduced-pressure ammonia-based nitriding atmosphere, allowing for stable nitriding treatment in a short time. Furthermore, with the ultra-low temperature treatment (COOL PLUS) option, it reduces residual austenite and stabilizes the parts both mechanically and dimensionally. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"SWP" is an original grinding wheel shaping machine from Sanwa Seiki Co., Ltd., which handles a large number of gear grinding machines. In addition to the rotary dressing device, it is also possible to install a tool-type dressing device, making it suitable for the finishing of finer screw-shaped grinding wheels. The rough shaping of solid grinding wheels can be done in a short time, and the finishing shaping can achieve higher precision than conventional shaping machines. [Features] - Suitable for finishing finer screw-shaped grinding wheels - Rough shaping of solid grinding wheels is done in a short time - Finishing shaping is more precise than conventional shaping machines *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The SHS-204 is an original machine from Sanwa Seiki Co., Ltd. that can perform hob cutting operations with high precision and efficiency. It adopts the "wet type CBN creep grinding method" and "NC indexing." Exceptional cutting precision (surface roughness = Rma × 1.5μm), gear cutting accuracy, and an extended hob lifespan can be expected. Inputting processing conditions is extremely simple, requiring only the division, depth of cut, feed rate, and stroke width. 【Features】 ■ Adopts wet type CBN creep grinding method ■ Expected improvement in gear cutting accuracy and hob lifespan ■ Significantly reduced cutting time ■ Easy operation ■ Full cover prevents mist dispersion and improves the working environment *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Challenges and issues in creating programs for mold processing, such as 'mainly focused on discharge machining and electrode production, unable to create programs for direct engraving effectively,' can be resolved. If you are facing difficulties in upgrading your company's cutting processing technology or improving the skills of your in-house engineers, please feel free to consult with us. For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

To maintain and improve a company's competitiveness, it is essential to enhance the technical skills of young talent. Increasing the productivity of the workplace also requires maximizing the use of machinery and equipment to improve operational rates. Would you like to strengthen the production capacity of your machining site through the skill development of younger employees? We provide practical guidance from the basics of cutting processing to applied techniques that are useful on-site. If you are facing challenges with training CAM operators or improving workplace productivity, please feel free to consult us. *For more details, please refer to the PDF document.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Are you having trouble creating CAM for mold processing? □ I want to create molds for more complex products, but I'm struggling with CAM creation. □ I want to reduce outsourcing requests and resolve the shortage of machining program supply. □ I want to eliminate differences in individual skills and shorten CAM working time. □ I want to make inexperienced individuals immediately useful, but it takes time for them to become proficient, etc. If you are having difficulties with training in-house engineers or creating CAM programs, please feel free to consult with us. We provide practical guidance from basic knowledge of cutting processing to applied techniques and CAM skills that are useful on-site. * For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

- I want to improve the processing methods to be more efficient, but I am not able to tackle it effectively. - I want to shorten processing time without compromising processing accuracy and quality. - I want to reduce processing troubles. - I am anxious about whether the issues will recur even after taking measures, etc. If you have any concerns, please feel free to consult with us. In the PDF materials, we introduce our CAM program creation training. - Points for solving challenges and issues: "Proposal of new processing methods" and "Human resource development and technology inheritance." - Scope of education and guidance: Total support for the process from CAM creation to processing. - Introduction of guidance examples: Education of young CAM operators and solving processing quality issues, etc.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The resin part and the metal part can be separated. It can be sorted during disposal, and it features an easy-to-use anti-slip mechanism. 【Features】 ■ Easy-to-turn resin flag shape ■ Can be separated and disposed of as metal and resin with a single removal ■ Size can be identified by the color of the resin ■ Various tip shapes are available *For more details, please contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "D-Bar (Coating Application Bar)" is a coating application bar that has been improved from the widely used wire bars in the film and specialty paper coating industry, featuring grooves formed directly in the material of the bar itself. Utilizing the mold technology that our company has developed over many years, it is adopted by many customers in mass production processes, taking advantage of features not found in conventional wire bars, especially as demands for coating film thickness accuracy and quality improvement in multilayer coatings increase. 【Features】 - The wide valley bottom design minimizes clogging and offers excellent cleanability. - Being a one-piece design through plastic processing eliminates concerns about wire breakage or misalignment. - It allows for arbitrary shapes without being constrained by wire diameter. - The shape can be selected according to the required coating amount or coating liquid. *For more details, please refer to the external link or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Various "Vacuum Heat Treatment Furnaces" from France's BMI Corporation We offer a rich lineup including "Vacuum Gas Quenching Furnaces" for high-temperature heat treatment and brazing, as well as the "B5_R Series" of "Low-Pressure Vacuum Furnaces" (Vacuum Tempering Furnaces) suitable for low-temperature heat treatment with inert gas convection. [Contents] ■ Vacuum Gas Quenching Furnaces ■ Vacuum Oil Quenching Furnaces ■ Low-Pressure Vacuum Furnaces (Vacuum Tempering Furnaces) ■ High-Temperature Vacuum Quenching Furnaces ■ Specification List ■ Thermochemical & Special Treatments, etc. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The compact BMICRO series is a space-saving and low-cost vertical vacuum gas quenching furnace, ideal for small-scale and low-volume production as well as research applications, with a maximum processing temperature of 1250°C. There are two types: BMICRO20/30 Maximum load capacity is 20kg. Loading space of Φ200mm and height of 300mm. BMICRO30/45 Maximum load capacity is 50kg. Loading space of Φ300mm and height of 450mm. Both models can be equipped with a low-pressure carburizing option (ALLCARB). The ALLCARB process, with over 20 years of proven performance, allows for deep carburizing layers to penetrate even the smallest internal holes.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "B8_T Series" from BMI, handled by the OSG Group Sanwa Seiki, is a horizontal vacuum gas quenching furnace designed for high-temperature heat treatment and brazing. In addition to conventional vertical cooling, it is capable of uniformly cooling large parts thanks to BMI's unique rotating flow cooling system. This reduces heat treatment distortion that is prone to occur with large components and shortens the time required for correction work. B8_T Series lineup: B83T - Load capacity 200kg, Width 450mm x Height 450mm x Depth 600mm B84T - Load capacity 600kg, Width 600mm x Height 600mm x Depth 900mm B85T - Load capacity 1000kg, Width 900mm x Height 700mm x Depth 1200mm As an option, low-pressure carburizing treatment (ALLCARB) is also available.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The low-pressure vacuum furnace B5_R series for low-temperature heat treatment maintains a temperature distribution of ±3°C within the heating chamber. Its excellent thermal uniformity enables heating and cooling in a short cycle, contributing to high productivity and profitability. The low-pressure nitriding process (ALLNIT process) uses a reduced-pressure ammonia-based nitriding atmosphere, achieving stable reproducibility and short processing times. It is an option for the B5_R series with nitriding capabilities effective for hot working tools (molds, punches, injection nozzles, etc.), cold working tools (shears, rotary combs, etc.), and cutting tools, particularly high-speed steel (HSS). Additionally, the ultra-low temperature treatment option (COOL PLUS) is effective in reducing residual austenite and stabilizing components.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We offer a lineup that can accommodate a wide range of usage purposes, including bimetal band saws that are robust and highly durable, suitable for heavy cutting and difficult materials, carbide band saws that boast exceptional cutting performance and high efficiency, and diamond electroplated band saws that can cut any material.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The D-Bar from OSG System Products is a wireless bar that doesn't use wire. There are numerous advantages that come from not using wire. Because it's not wire... It doesn't loosen or break There are no gaps It has excellent cleanability A wide variety of serrated shapes And so on...

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration