1~24 item / All 24 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Inquiry FormBefore making an inquiry

Download Profile1~24 item / All 24 items

Filter by category

Traditionally, the use of resin in the plunger system was unimaginable in the world of aluminum die casting. ~Part Characteristics~ 【Special Resin】 High heat resistance and durability suppress galling and backflash within the sleeve. 【Surface Treatment】 Special treatment retains lubricating oil, suppressing galling. 【Special Welding】 A special metal with low affinity for aluminum is coated (with a buildup process), suppressing aluminum melting. ~Effects~ * Prevention of chocolate stops due to galling suppression. * Extension of sleeve life due to backflash suppression. * High aluminum filling rate achieved through resin filling within the sleeve. * Suppression of aluminum temperature rise due to high thermal insulation. The structure is also very simple, reducing replacement effort (which is a welcome aspect for everyone on-site). The combination of part characteristics is flexible and can be customized according to user preferences. We kindly ask you to consider the new stance of the plunger system, 【MOHF】.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"FASTCOOL" is a high-speed cooling tool steel developed for hot forming. It achieves an extremely high thermal conductivity of 54 W/m·K, and after heat treatment, it reaches a hardness of approximately HRC 44 to 53, demonstrating excellent material properties. With high wear resistance, "FASTCOOL-50" is suitable for hot stamping, injection molding, and materials for molds, inserts, and tools. "FASTCOOL-55" excels in strength, toughness, wear resistance, seizure resistance, and erosion resistance, making it suitable for tools for hot processing, aluminum die casting molds, and extrusion tools for aluminum and brass, allowing you to choose according to your needs. 【Other Features】 ■ Excellent polishing performance ■ Significantly reduces the frequency of mold maintenance ■ Dramatically decreases the defect rate of complex molded parts ■ Global procurement available, including Europe, America, and Asia Our company has a long-standing track record as a stock trading company, and we strive to deliver the necessary products quickly and reliably to our customers. *For more details, please refer to the materials. We also introduce examples of adopting this steel for runner breakage countermeasures.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

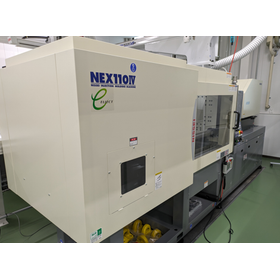

Our company is engaged in the fluororesin-related business. Leveraging our expertise in high-strength mold manufacturing, we propose solutions for extending lifespan and adjusting molding. We have established high-precision equipment and environments. 【Features】 ■ Dedicated injection molding machines for fluororesins and high-performance inspection equipment are permanently installed. ■ Comprehensive management from design and manufacturing of molds and tools compatible with difficult-to-mold resins like PFA to trial injection. ■ Proposals for molds and parts with special corrosion-resistant welded coatings. ■ Contributing to various fields such as semiconductors and medical applications. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Are there any worn or damaged screws? Are you struggling with insufficient strength? In that case! With our original system, "Nikumori-kun," we can restore the shape of damaged components and increase strength by using plasma arc or laser light to add high-alloy powder. Parts that are consistently worn can be repaired with buildup, allowing for repeated use. Instead of remaking the entire product, we can enhance performance at a low cost by adding high-alloy powder only to the necessary areas. Additionally, our robotic welding using "Nikumori-kun" enables uniform and stable processing.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Some molds are made by press-fitting carbide nibs, but after using them as molds, when returning the raw materials, the value of the carbide can often diminish. While not everything can be removed, I would appreciate it if you could consult with me regarding any molds that are no longer needed.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Blue semiconductor laser welding" refers to a laser specification that enables high-quality welding, particularly for copper materials, in the industrial field. The laser light referred to as blue laser has a wavelength of 450nm, which is in a different wavelength range than IR lasers. It is a laser light with a high absorption rate for elements such as copper. The use of blue semiconductor laser light not only opens up new possibilities for processing non-ferrous metals like copper and gold but also for bonding between different metals. 【Features】 ■ Beam diameter is approximately Φ0.6mm or Φ1.0mm ■ Achieves a welding depth of about 2.0mm through a hybrid optical system with IR optics ■ Layered welding using filler materials such as copper wire is also possible Powder materials for buildup can also be handled *For more details, please download the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Tokumori-kun" is our original automatic system, which is one of the teaching methods available for "Nikumori-kun." It supports the calculation of layered programs for 3D solid models. Additionally, since the edge areas often have different welding condition instructions, it is easy to separate the program calculations in advance, providing many practical options. [Features] Developing additional functions as needed! - Specialized in meat buildup, with comprehensive software - Supports the calculation of layered programs for 3D solid models - Equipped with many practical options *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Shrink fitting is a method where a case is heated to around 400 to 500 degrees, and a room temperature nib is inserted inside. As the case cools down, it integrates with the nib to form a high-strength component. The difficulty of shrink fitting varies widely depending on the shape and size of the component, the material, and the interference fit. However, the advantage of the "Preheat-kun" is that it uses a contact heating method from below, so if the upper surface of the workpiece reaches 480 degrees, the lower surface will always be slightly higher, reducing the risk of getting stuck during the process. Additionally, it is suitable for small lot setups (low-cost products), making thermal management of each individual workpiece easier.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a laser cladding equipment equipped with a 10 kW laser oscillator. At Nankai Steel, we offer a wide range of services, including contract work for molds and consultations for automated system equipment. Additionally, since we also use PTA equipment on-site, we can accommodate specifications comparisons. We provide torches suitable for flat shapes as well as those capable of handling recessed shapes. Metal powder is used for the application, and we also handle some sales of the powder. In terms of development, we are currently collaborating with universities to develop welding materials with high resistance to softening at high temperatures. We conduct measurements using a 3D scanner to prevent undercuts. Furthermore, we are also focusing on the development of automated systems.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company conducts various designs and drawing creation using 2D and 3D CAD. We provide a consistent response from conceptual proposal → design → manufacturing → assembly and adjustment → measurement and trial. We can achieve longer lifespan, cost reduction, and shorter delivery times. Leveraging the advantages of being a "material supplier," we connect material proposals to ease of manufacturing. We offer a wide range of 3D design services from product design to equipment design. 【Features】 ■ Various Designs - Design of dedicated equipment machines, general jigs ■ Reverse Engineering - Analyzing the structure of existing products using 3D measuring machines, and creating 3D models and drawings ■ Product Design Assistance - Converting paper drawings into 2D CAD data, creating 3D models from drawings ■ Mold Design - Die-casting molds, press molds, forging molds, die-casting trimming molds *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company provides mold maintenance services. We can handle everything from material procurement to processing and maintenance in a consistent manner! We take care of molds after mass production, performing cleaning, repairs, replacements, and assembly to ensure the molds are ready for the next mass production plan. In "forging die set maintenance," we remove and clean lubricants and release agents used during mass production. We will begin work after consulting with the customer regarding repairs or new replacements. We also accept requests for complete new production. Additionally, we offer "aluminum die-casting mold maintenance" and "equipment jig manufacturing," so please feel free to contact us when needed. 【Features】 ■ Forging Die Set Maintenance - Removal and cleaning of lubricants and release agents used during mass production - Work begins after consulting with the customer regarding repairs or new replacements ■ Aluminum Die-Casting Mold Maintenance - Removal of release agents and adhered aluminum during mass production, and repair by adding material to the mold - Replacement and assembly of parts/hoses - Non-contact measurement of worn areas for modeling, followed by overlay welding and machining *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document introduces the types and characteristics of alloy die casting, as well as our company's initiatives. "Alloy die casting" is a type of casting method where alloy raw materials such as aluminum, zinc, and magnesium are melted at high temperatures and poured into molds. Our company is engaged in supplying materials (and processing) to casting manufacturers, as well as providing production molds and surrounding tools. Additionally, we carry out comprehensive "mold maintenance," including piping, with dedicated staff. We will respond to our customers' needs by leveraging our "casting mold know-how." [Contents] ■ What is die casting? ■ Types of alloy die casting - Aluminum alloy die casting - Zinc alloy die casting - Magnesium alloy die casting ■ Our company's initiatives in the die casting field *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document presents customization examples for the mold preheating device "Yone-kun" for installation carts and other equipment. It introduces examples such as a "cart with enclosure" that has insulation fabric attached to the outside to prevent burns even if an operator accidentally touches it during heating, as well as a "rotating installation example" with a thermal cover (a metal enclosure for efficiently heating welding work) that allows operators to set it up without direct hand contact. Specifications not included in the document can be customized. Please feel free to consult us. [Contents] ■ Dedicated cart example I for "Yone-kun" (for welding applications/movable) ■ Dedicated installation example II for "Yone-kun" (for welding applications/rotating) ■ Dedicated cart example III for "Yone-kun" (for welding applications/lifting platform) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document presents customization examples for the mold preheating device "Yone-kun." It introduces modifications and additional features based on the basic specifications, including general specifications for one-stage & two-stage control, full ON/full OFF, logger specifications, mold temperature control specifications, and tower light specifications. Specifications not included in the document can be customized. Please feel free to consult with us. 【Contents (partial)】 ■ General specifications (one-stage & two-stage control, full ON/full OFF) ■ Logger specifications (data saved to USB) ■ Abnormal temperature rise detection specifications (suspected heater degradation or disconnection) ■ Mold temperature control specifications (assuming sensor temperature installation on the mold) ■ Logger specifications for "mold temperature and head temperature" ★ If you wish to conduct a heating test, please feel free to contact us. * For more details, please refer to the PDF document or feel free to inquire.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

<What is a 5-axis machining machine?> It is a machine that adds two axes, a rotational axis and an inclined axis, to a machining center. <Features of Our Services> We have two high-precision machines: the Yasuda "Vi40" and the large-scale Makino "D800Z." We also have a CAD/CAM environment that supports 5-axis machining. We can handle various processes including drilling, shape processing, as well as turning, machining, polishing, welding, and more in-house. We can provide a comprehensive service from mold materials to heat treatment, and we can also accommodate requests for specific processes only. *Water pipe processing refers to the machining of water holes that circulate cooling water to cool the mold. *For more details, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

What is DP7000? It is a dedicated plate stock for die holders that combines the large forging technology of Daido Steel and the large facilities of Nankai Steel. 【Features】 ■ Forging Achieves a maximum width of 2000 mm with excellent toughness through the forging enhancement of the 7000T press. ■ Heat Treatment Suitable hardness of HS47±2 for die holders. ■ Stock Abundant stock enables immediate delivery. ■ Cutting Cut to customer-required sizes with one of the largest cutting machines in the country. ■ Processing Processed to customer specifications with a large five-sided machining center. What is a five-sided machining center? It is a machine that processes five sides of a material, excluding the bottom side where the material is fixed to the machining equipment, for cutting operations such as molds and machine parts. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Specifically, we capture and analyze the requested item using a "3D image scanner" and prepare it as a 3D model of the mold using modeling software. The imaging accuracy reflects details such as punch marks and engravings, achieving a precision level of several tens of micrometers. Please feel free to consult with us first. As shown below, we provide suitable reverse engineering not only by simply refining the appearance of the model but also by incorporating insights from mold design. 【Case Studies and Features】 ■ In hot forging molds, we have already achieved several models shortly after introduction. (Introduction of scanning equipment: March 2020) ■ In mold processing operations, we mainly receive models from customers for processing, but we possess knowledge regarding "mold models." ■ As a mold material trading company, we also have insights into mold materials and heat treatment, covering the entire field of molds. ■ We have experience collaborating with customers on mold design and mechanical device design. ■ We also have a track record of "design support" as a business to assist with operations. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Mainly, molds for the automotive and industrial machinery sectors account for a large part of our achievements, but we also cater to various fields including electrical, aerospace, and chemical industries. Leveraging the knowledge of molds and mold materials cultivated over 60 years of establishment, as well as our business network, we also engage in proposal-based sales to address our customers' concerns. We have various in-house equipment, including 5-axis machining machines, at multiple locations. You can also trust us with quality control. 【List of Our Services】 - Cold/Hot/Warm forging molds (SKD61, SKD11, SKH51, etc.) - Hot stamping (press) molds - Aluminum die-casting molds - Rubber molding molds - Mold materials (other materials are also accepted) - Machining (small to large) - Build-up welding (TIG, plasma, laser, contract and equipment consultation) - Heat treatment (deoxidized, vacuum, salt) - Surface treatment (gas nitriding, ion nitriding) - Coating (TiC, TiCN) - Plating (hard chrome) - Polishing LAP *Regarding heat treatment and surface treatment, we do not have in-house equipment, but we can accept the entire process as a contract. - Shape inspection (non-contact/contact, 3D image camera) - Reverse engineering

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company prices each type of steel based on the distribution prices of special steel manufacturers. As a result, we receive high evaluations from customers when compared to regular iron scrap prices. We can also perform steel type selection at our company (however, a sorting fee will be charged separately). Additionally, we are enhancing our collection and delivery services, ensuring a smooth collection pace. *Please feel free to consult us regarding collection boxes and other requests. 【Business Content】 ■ Cutting and sales of special steel, tool steel, and mold steel ■ Processing and sales of forging molds and mold parts ■ Processing and sales of die-casting molds and mold parts ■ Material and processing sales of die holders for forging presses ■ Processing and sales of main molds for die-casting molds (affiliated company: Amix Co., Ltd.) ■ Processing and sales of molds and mold parts for hot presses ■ Manufacturing and sales of processing release agents for molds ■ Sales of welding systems for molds ■ Mold recycling business *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Nankai Maldives Co., Ltd.'s affiliated company "NK Mentech Co., Ltd." conducts various on-site machining from the design to construction of transportation lines for industrial machinery (forging machines, press machines, casting machines, etc.). The order reception window is handled by "Nankai Steel Materials," so if you are having trouble with industrial machinery maintenance, please feel free to consult us. 【Owned Equipment (Excerpt)】 <On-site Processing Machines> ■ Horizontal Boring Machine (Ikegai) ■ Gantry Planomiller (Marufuku) ■ Vertical Lathe (Shibaura) ■ Radial Drill (KAO MING) ■ General-purpose Lathe ■ General-purpose Milling Machine (OKK) *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company is a trading firm that engages in everything from the sale of mold materials and specialized machinery to the processing and production of molds and tools. We provide high-quality materials and precision products that support the manufacturing of automobiles, motorcycles, industrial machinery, construction machinery, and aircraft. We have earned the trust of a wide range of customers in various markets. Leveraging our integrated system and know-how that covers everything from procurement to production, we respond to the diverse needs of our customers. 【Business Activities】 ■ Sales of cutting and processing of special steel, tool steel, and mold steel ■ Processing and sales of forging molds and mold components ■ Processing and sales of die-casting molds and mold components ■ Sales of materials and processing for die holders used in forging presses ■ Processing and sales of master molds for die-casting molds (affiliated company: Amix Co., Ltd.) ■ Processing and sales of molds and mold components for hot presses ■ Manufacturing and sales of processing release agents for molds ■ Sales of welding systems for molds *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In today's welding sites, the inheritance of welding technology has become a very serious issue. In response, Nankai Moldi Co., Ltd. has developed the 'Nikumori-kun,' which combines robots and our heating device "Yohatsu-kun." With this system, even those who are not skilled in welding can perform buildup on molds, and we will achieve the inheritance of welding technology by quantifying welding data. **Features** - A system combined with robots and heating devices - Allows for mold buildup even without welding expertise - Enables quantification of welding data - Capable of generating robot trajectories from CAD data ★ Additionally, we are focusing on software development related to welding trajectories! *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Do you have any such requests? "I want to use it for mold baking work," "I want to heat it to high temperatures up to 650°C," "I'm looking for a high-temperature heater that can also cool down for welding applications," "I want to customize the shape and material of the heating head," "I want to customize the control specifications," "I want to add a signal light," "I also want to create a dedicated cart," etc. Our product has a fast heating rate and is safe and reliable as it does not use fire. If it's a small machine, it can reach 650 degrees in just a few minutes. It is also robust, making it suitable for field use. 【Features】 - Reliable heating from low to high temperatures - Maintains heating at the desired temperature - Temperature control is possible at specified locations (such as mold shape areas) - Comfortable operation with timer settings - Durable and long-lasting - Customization of control and heating head shape is available - Design provision can also be offered as a set with a cart You can determine the specifications by trying out a demo unit, ensuring reliability and peace of mind. *We have demo units ranging from small 200X350mm to large 650X800mm. Please contact us first. *We also accept inquiries for special specifications such as ceramic bodies.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The mold heating device "Yohne-kun" is a device that reliably heats molds, parts, and tools to deep levels. It solves concerns related to heating, such as feeling danger when working with burners or wanting uniform heating! Using it is simple! Just make contact with the heating head, and it will quickly and uniformly heat to deep levels. Additionally, temperature management is easy, which improves mold lifespan and the workability of welding and heat treatment. 【Features】 ■ Achieves preheating temperatures (200℃ to 250℃) in a short time. ■ Maximum temperature of the main unit is 650℃. ■ Heats uniformly across the entire surface, eliminating causes of deformation and distortion in the initial stages of forging. ■ Safe and secure operation even when unattended, as it uses electric heaters. ■ The heat source is specially developed, excelling in heating capacity and speed, with a long lifespan. *Custom specifications can also be provided according to your requests! *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration