1~30 item / All 30 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~30 item / All 30 items

Filter by category

In recent years, due to the effects of global warming, abnormal heat waves in summer have become the norm, increasing the risk of heat-related illnesses. Particularly in manufacturing environments, in addition to rising outdoor temperatures, the radiant heat from equipment and machinery further raises indoor temperatures. When combined with factors such as long working hours, the wearing of protective clothing, and insufficient ventilation, the risk of heat-related illnesses increases even more. To prevent health issues among employees and the resulting decline in productivity, appropriate temperature management and ensuring rest are necessary. However, it is a reality that thoroughly implementing measures across large factories and multiple work areas is challenging. This is where an efficient management system that incorporates the latest technology comes into play. The remote monitoring system "AMEROID CHANNEL" measures temperature and humidity within the factory in real-time and displays the heat index on a monitor, making the environment "visible." Additionally, when the values exceed the standard, alert emails are automatically sent, allowing employees to immediately understand the situation. Administrators can also check the status in real-time from a distance, making it a highly practical system that balances safety improvements with maintaining work efficiency.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the cleaning process, the oil and contaminants washed off from the workpiece return to the tank along with the cleaning solution. As cleaning continues, the amount of oil and contaminants in the tank gradually increases, ultimately leading to a decrease in cleaning capability and, consequently, poor cleaning results. One way to avoid this is through liquid replenishment, but Ameloid recommends the installation of a "centrifugal oil-water separator" that removes not only the floating oil but also the oil mixed into the cleaning solution. This maintains high cleaning capability and reduces the frequency of liquid replenishment. ■ Centrifugal Oil Separator Model UB This is a centrifugal oil-water separator that operates at 4,000 revolutions per minute. It forcibly separates the oil mixed in the cleaning solution using centrifugal force and automatically discharges it continuously. Contaminants solidify and are periodically discharged manually or automatically. ■ Centrifugal Oil Separator Model WF This is a centrifugal oil-water separator that operates at 10,000 revolutions per minute. It forcibly separates the oil mixed in the cleaning solution using centrifugal force and automatically discharges it continuously. Contaminants solidify and are periodically discharged manually. ■ Peace of Mind Before and After Installation We carefully listen to the properties of the liquid and the usage environment to propose suitable equipment and processing methods. Effectiveness confirmation tests can be conducted before installation. Additionally, to ensure that the equipment remains stable and continues to demonstrate its high performance, we have a comprehensive support and maintenance system in place after installation.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

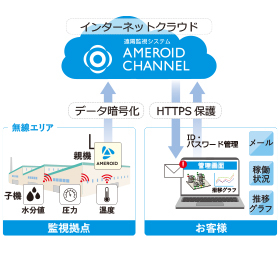

■Service Overview The remote monitoring system "AMEROID CHANNEL" by Ameroid is a cloud-based system that allows for real-time centralized management of equipment conditions within a factory. It instantly detects subtle changes and contributes to the prevention of potential troubles. There is no initial investment required, and we also provide a custom screen tailored for our customers. ■System Configuration and Communication Method - Information collected by sensors (subunits) attached to the equipment is received by the main unit. - Data is encrypted and transmitted to the cloud via 4G communication. - No installation work is required due to wireless communication. ■Security - The cloud is protected by HTTPS, ensuring high security. ■Real-Time Monitoring & Alert Function - Monitoring information can be checked anytime, 24/7, from a computer or smartphone. - An alert email is automatically sent when a pre-set threshold is exceeded. ■Graph Display & Report Generation - Measurement values are graphed, making it easy to intuitively grasp trends and patterns that may be difficult to see with numbers alone. - Regular reports and CSV output are utilized to support preventive maintenance and maintenance planning. ■Efficiency in Management - Centralized management of numerical data for all equipment. - Efficient maintenance based on data is possible.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Heating Method】 The heating methods for the vacuum distillation apparatus are generally divided into heat pump cycles or steam. In addition to these two, our company also manufactures a "steam recompression method" that efficiently generates energy by recompressing the used steam, achieving low running costs. 【High Concentration Rate】 Regardless of the method, as distillation continues, the target liquid gradually thickens and eventually reaches the limit of concentration. However, when our original "centrifugal oil-water separator" is combined with the distillation apparatus, the concentration rate significantly improves compared to processing with the distillation apparatus alone. 【Low Maintenance Frequency】 Heating coils gradually accumulate scale, reducing thermal conductivity, so regular cleaning is necessary. However, when combined with the centrifugal oil-water separator, the degree of accumulation changes, reducing the frequency of cleaning. ● Vacuum Distillation Apparatus EVP Type - An apparatus that reduces the volume of waste liquid through vacuum distillation. - Heating methods can be selected from three options: heat pump, steam, and steam recompression. - Models with a daily capacity of 350L to 10,000L are available. ● Centrifugal Oil-Water Separator UB Type - Our original centrifugal separator that simultaneously performs oil-water separation and sludge removal. - When combined with the distillation apparatus, it improves concentration rates and maintenance characteristics. - Suitable models are selected according to the specifications and size of the distillation apparatus.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The waste oil regeneration device selects suitable models from centrifuges, coalescers, and filters. ● A centrifuge is a device that forcibly separates substances with different specific gravities using centrifugal force. It is suitable for recovering water and impurities from waste oil, especially when there is a large amount of impurities in the waste oil. ● A coalescer is a device that collects fine moisture mixed in waste oil by coalescing it into larger droplets. It is suitable when a large amount of fine moisture is difficult to separate. ● A filter simultaneously absorbs moisture and filters out fine impurities. It is used as a final finishing step when precision is required in the waste oil regeneration process. ● Dry air may be added to the waste oil regeneration device. Dry air captures moisture mixed in the oil as water vapor. Continuous input is expected to lead to an early decrease in moisture levels. The suitable model is selected after analyzing the particle size distribution of impurities and moisture content in the waste oil and conducting effectiveness confirmation tests. A waste oil tank and waste oil regeneration device equipped with various sensors for liquid level, moisture content, pH, temperature, and viscosity are systematized for remote monitoring. Once the desired precision is reached, regeneration is automatically completed.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "UQ Filter" is a device that primarily removes oil from compressor drain water and continuously meets the discharge standards of the Water Pollution Control Law. By combining three adsorption technologies, it eliminates oil and odors. In conventional adsorption systems, managing the filter's lifespan is challenging, requiring daily inspections to visually or analytically check the outlet for any cloudiness caused by oil. The "UQ Filter" is equipped with a turbidity sensor that alerts users to the optimal replacement timing of the adsorbent material. This ensures reliable management and operational efficiency, allowing for safe usage. *For more details, please feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "FK-type cyclone" is a device that utilizes the centrifugal force generated by the flow of liquid to efficiently separate and collect sludge (foreign substances). Since it does not use consumables like filters and has no moving parts, there is no concern about clogging or failure, allowing for stable operation. With its simple structure, maintenance is also easy, enabling continuous collection of foreign substances with minimal trouble and low cost. *For more details, please feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "REX Filter" is a deep filtration filter compatible with aqueous solutions and oils. The cartridge sizes range from small to large, and the filtration precision can be selected from 1μ to 100μ. The structure, which has a higher density from the outside to the inside of the filter cartridge, effectively captures debris not only on the surface but also internally, achieving high precision and long-lasting filtration. Additionally, it is equipped with a pressure sensor that alerts you to the optimal replacement timing of the element. This allows for stable management of liquid cleanliness, ensuring safe use. *For more details, please download the catalog or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an oil filter that is ideal for overhauls and oil change operations. It employs a pleated surface filtration method with a bellows-like filter element, reducing oil flow resistance and achieving high flow rate processing. It shortens the oil purification time and demonstrates stable oil purification performance even during large-scale processing. *For more details, please feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Floating Oil Recovery Device FU Type" is a floating oil recovery system composed of a float suction, pump, and oil-water separation tank. It efficiently sucks in floating oil in response to fluctuations in the liquid level, and the floating oil is continuously discharged from the oil outlet through a partition plate. The purified water is returned to the tank. With no moving parts, the risk of failure is low, contributing to stable oil-water separation and reduced running costs. *For more details, please download the catalog or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "CJC Filter" is a high-performance oil purification machine representing Ameloyd, featuring a high-density element with an absolute filtration accuracy of 3μm. It maintains a cleanliness level equivalent to ISO 16/14/11, effectively removing fine foreign particles and moisture. Additionally, it is equipped with a pressure sensor that alerts users to the optimal replacement timing of the element, supporting improved oil cleanliness management and stable operation. By utilizing an offline method that circulates oil within the tank, it helps maintain high overall oil cleanliness, contributing to a reduction in the frequency of line filter clogging. It preserves cleanliness at new oil levels, reducing the risk of failure in hydraulic equipment such as servo valves and turbines, while also helping to lower maintenance costs, decrease oil replacement frequency, and reduce waste oil. *For more details, please download the catalog or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "PTU Filter" is a high-performance device that combines a CJC filter with an absolute filtration accuracy of 3μ and a coalescing oil-water separator. By filtering out fine contaminants mixed in the oil and efficiently separating moisture, it restores the clarity of cloudy oil to that of new oil. It is ideal for equipment such as hydraulic systems, turbine systems, and vacuum pumps, where water and foreign substances are likely to mix, contributing to stable operation, extended oil change intervals, and reduced waste oil. *For more details, please download the catalog or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "ROT filter" is one of the representative filtration filters of Ameloy that employs a deep filtration method with filter elements. The filtration accuracy can be widely selected from absolute 5 to 75μ, and it is compatible with oils and aqueous solutions of low to high viscosity. It is equipped with a pressure sensor that has a function to notify the timing for element replacement, supporting liquid cleanliness management. Additionally, by circulating and filtering the liquid in the tank offline, it reduces the frequency of clogging in the line filter. By removing contaminants from the oil and maintaining high cleanliness, it helps reduce the failure rate of equipment such as rolling machines and vacuum pumps, lower maintenance costs, decrease the frequency of oil replacement, and reduce waste oil. *For more details, please download the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Amyloid Separator AS Type" is a mid-speed (3,000 to 5,000 RPM) centrifuge developed through years of improvements, capable of handling water, oil, and all types of liquids. It separates and solidifies sludge from liquids with powerful centrifugal force. The automatic discharge makes processing easy. With a user-friendly touch panel control system, it is a tough and high-performance centrifuge that excels in ease of use on-site. By removing impurities from various liquids used in factory production lines, it contributes to increased productivity, improved quality, extended liquid lifespan, and reduced waste treatment costs. *For more details, please download the catalog or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Centrifugal Drying Device Model MJ" is a high-performance oil-water separator unique to Amerloid, unlike any other. It automatically discharges free water and continuously removes water mixed with oil. At the same time, it also removes fine contaminants in the oil using centrifugal force, restoring the cloudy oil to a state similar to that of transparent, high-purity new oil. Even in environments where water continuously mixes in, its overwhelming dewatering performance is effective, eliminating the need for daily water removal tasks. This not only prevents sudden troubles caused by reduced lubrication due to water contamination but also significantly reduces maintenance labor, costs for new oil and waste oil, and minimizes opportunity losses due to production downtime. *For more details, please download the catalog or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Centrifugal Oil Separator Model UB" is a dual-purpose centrifugal separator that performs oil-water separation and sludge removal for various aqueous solutions. The oil separated from the aqueous solution is continuously discharged from the oil outlet, while the collected sludge is solidified and periodically discharged from the sludge outlet. This reliable and tough oil-water separator is active in a wide range of fields, from purifying various aqueous solutions used in factory production lines to reducing the burden on wastewater treatment facilities. *For more details, please download the catalog or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "WF type centrifugal oil separator" is a high-speed centrifuge that removes oil from aqueous solutions such as coolant and cleaning liquids. With a powerful centrifugal force of 10,000G, it efficiently separates oil and water, restoring clarity to liquids that have become cloudy with oil. Additionally, it can simultaneously recover fine contaminants mixed in the liquid, keeping it in a clean state. By continuously collecting oil and sludge from the coolant, it helps suppress bacterial growth and is effective in odor control. Its compact unit structure allows for space-saving installation. It accommodates a variety of liquid types and supports stable liquid management in production environments. *For more details, please download the catalog or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Super Dry SDA Type" is a core-less oil-water separator. It coarsens and separates fine water droplets dispersed in oil, restoring clarity to the cloudy oil. At the same time, it removes foreign substances larger than 10μm. It is effective in cases where a large amount of water is mixed into the oil, which cannot be handled by water-absorbent filters, contributing to the reuse of oil and equipment protection. *For more details, please download the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Evaporator EVP type" is a device that distills wastewater for concentration and volume reduction. By adopting a heat pump cycle, it enables high-efficiency processing with minimal thermal energy. The heating section of the concentration tank uses a submerged coil, which also reduces maintenance load. By combining it with a "Centrifugal Oil Separator UB type" as a pre-treatment, it achieves a higher concentration rate than conventional distillation devices. Additionally, the distilled water can be reused as industrial water, and by incorporating post-treatment options such as the "Centrifugal Oil Separator WF type" or "UQ Filter," it can be directly discharged into the sewage system. *For more details, please download the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Dry Separator GR40" is a wastewater treatment device that combines a centrifuge and a drum dryer. It dries slurry into a powder form with a moisture content of 40% or less, achieving up to a 70% reduction in industrial waste volume compared to filter presses. It contributes to environmental improvement by reducing waste volume, lowering processing costs, and suppressing CO₂ emissions and odors. Its fully automated operation without filter cloth also reduces the burden of work. The "Dry Separator GR40" has received numerous prestigious awards, including the Special Award at the Manufacturing Japan Grand Prize, as a new technology that replaces filter presses. ● Awarded the Special Award at the 6th Manufacturing Japan Grand Prize ● Awarded the Grand Prize at the 32nd Kanagawa Industrial Technology Development Award ● Awarded the Minister of Economy, Trade and Industry Award at the 41st Excellent Environmental Equipment Awards ● Awarded the Grand Prize in the Environment (Eco) category at the 5th Kanagawa Industry Navi Awards ● Awarded the Hyogo Prefecture Invention Award in 2017 *For more details, please download the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "KR5 Type Centrifugal Chip Dehydrator" is a device that efficiently separates and removes cutting oil adhering to chips discharged from machine tools using centrifugal force. By de-oiling the cutting oil attached to the chips, it resolves issues such as troubles in the chip recycling process and long drying times. Additionally, by combining it with the "UB Type Centrifugal De-oiler" in the subsequent stage, it enables the reuse of cutting oil, helping to reduce oil carry-out loss and consumption. It can handle both ferrous and non-ferrous materials and is suitable for both water-soluble and non-water-soluble cutting fluids. It is also capable of constructing a series of systems combined with peripheral equipment such as crushers, conveyors, and drum reversers. *For more details, please download the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Coolant Vacuum Cleaner (Centrifugal Type) GH9V" is a coolant vacuum cleaner equipped with Ameloyd's centrifugal separation technology. It efficiently collects accumulated grinding powder and fine sludge from the coolant tank of machine tools using a handheld nozzle and powerful centrifugal force. Since it does not use disposable bags like non-woven fabric, there are no daily consumables required, and there is no decrease in suction power. It allows for cleaning without draining the coolant liquid, and its compact design makes it easy to handle by one person and simple to move. In addition to extending the coolant replacement cycle, it also enhances productivity and quality in cutting and grinding processes, and is effective in preventing coolant corrosion during the summer. *For more details, please download the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Coolant Vacuum Cleaner (Bucket Type) VC2" is an air-driven coolant vacuum cleaner equipped with a large bucket that has fine mesh. It sucks up chips accumulated in the tank using a handheld nozzle and collects them in the bucket. The main body is made of transparent acrylic, allowing for easy visibility of the collected amount, and it is also easy to discharge. It does not use non-woven fabric bags, eliminating the need for everyday consumables. Cleaning can be done without draining the coolant liquid, and its compact design makes it easy to handle and move by one person. It effectively extends the coolant replacement cycle, improves quality and productivity, and provides corrosion prevention during the summer. *For more details, please download the catalog or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "CJC Filter EP Type" regenerates waste fuel extracted from fuel tanks during automobile dismantling into a state that can be safely reused. Simply filtering gasoline or diesel extracted from the fuel tank with a cloth is insufficient; it is necessary to thoroughly remove debris from drilling holes, moisture, rust, and fine impurities. The "CJC Filter EP Type," with its high filtration precision, effectively captures and removes these impurities, allowing gasoline and diesel to be safely used as regenerated fuel. *For more details, please download the materials or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "CJC Filter BG Type" maintains the lubricating oil in the gearbox at a level equivalent to new oil, bringing bearing-related troubles in wind turbines close to zero. Needless to say, wind turbines generate profits when they are operational. Conversely, downtime due to troubles means significant losses. It is said that as much as 80% of wind turbine issues are caused by lubricating oil, making oil management essential for the stable operation of wind power generators. The "CJC Filter BG Type" is a high-performance filter that astonishingly removes impurities, wear particles, and moisture generated within the gearbox, ensuring that the lubricating oil is always maintained at a level equivalent to new oil. It is standardly adopted in wind turbines worldwide, with over 80,000 units currently in operation. *For more details, please download the catalog or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The RISO unit has been born for over 30 years, combining a medium-speed centrifuge and CJC filter. Primarily, the RISO unit has received overwhelming support for coastal vessels, and we have added a dewatering function using a dry method. The dry method is a completely new oil-water separation technique developed uniquely by Ameloyd, which can astonishingly remove moisture from lubricating oil that has become cloudy due to water contamination. Like conventional products, it has excellent maintainability, requiring no complicated disassembly and maintenance. With an extremely low workload of changing the CJC filter once a year and cleaning the centrifuge once a month, it keeps the lubricating oil in a consistently clean state. ≪ For more details, please contact us or refer to the catalog ≫

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The OFRO unit has been born from the combination of a centrifugal separator and a precision filter for over 30 years. Primarily used as a C heavy oil purification device for coastal vessels, the OFRO unit has now added a dewatering function using a dry method. The dry method is a new oil-water separation technique developed uniquely by Amerloid, which astonishingly removes moisture mixed with fuel oil. Thanks to the precision filter and high dewatering capability, clean fuel is always supplied to the engine. The "NEW OFRO unit" is reliable even when a sudden influx of water occurs. A water detection sensor will timely alert you with an alarm. Additionally, it has very high maintainability, requiring no complicated disassembly for maintenance. With a precision filter replacement once a year and a centrifugal separator cleaning once a month, the operational burden on-site is minimal for this fuel purification device. * The water sensor-equipped version is optional. * There is also a fully automatic centrifugal separator that requires no cleaning. For more details, please contact us or refer to the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "AL Automatic Backwash Filter" is a filter for diesel engine lubricating oil that employs an automatic backwash method. It automatically backwashes the filter using an air cylinder drive, reversing the flow of oil to eliminate clogging. This keeps the lubricating oil in a constantly clean state, contributing to stable engine operation and reduced maintenance. The filter element features a highly durable structure with stainless steel wire wrapped around a core. It can be cleaned and reused, and the filtration precision can be selected according to the application. Additionally, its design allows for easy open inspection, making it a product with excellent maintenance characteristics. *For more details, please download the catalog or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Magnetic horsepower" is a device that changes the properties of water through the action of powerful magnets, preventing the attachment of marine organisms. By installing it in seawater pipes, such as those before the engine's L.O. cooler, it helps suppress the attachment of shells, the formation of scale, and rust, thereby reducing maintenance costs during docking. Furthermore, improvements in engine fuel efficiency and operational efficiency can also be expected. *For more details, please download the catalog or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Evaporator ES Type" is a device that distills waste liquid as much as possible to recover valuable materials from it. It adopts a heat pump cycle, enabling energy-saving processing with minimal heat input. The distilled water can be reused as industrial water, and by combining it with the "Centrifugal Oil Separator WF Type" or "UQ Filter" in the subsequent stages, the water quality can be further improved, allowing for discharge into sewage systems. *For more details, please download the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration