1~39 item / All 39 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF1~39 item / All 39 items

Filter by category

This document introduces temporary repair materials used for deck board repairs. It includes several types of leak-stopping materials, such as epoxy putty that uses a type where the resin and hardener are combined in one tube, and a hard non-curing putty based on wax called Althite Stick. It is a useful reference, so please take a moment to read it. [Contents] ■ What is temporary repair material ■ Various types of leak-stopping materials *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Repairs using drill screws and rivets are effective in cases of significant leakage or when reinforcing the tank. Drill screw repairs involve a method that uses "drill screws" to press-fit rubber sheets by drilling holes, tapping, and fastening to the repair plate all at once. Rivet repairs are an effective method when you want to reinforce the tank. 【Features】 ■ Drill Screw Repair - Reduces the risk of leakage during penetration - Can handle cases of significant leakage ■ Rivet Repair - The backing plate is fixed semi-permanently - A construction method with a high risk of leakage of contents *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document introduces preventive maintenance suitable for corrosion and thinning at the contact points between pipes and supports. It provides a detailed explanation using images and diagrams about the areas where corrosion and thinning are likely to occur at the contact points between pipes and supports, as well as the strengths of corrosion prevention measures using composite repair. This is a useful reference, so please take a moment to read it. [Contents] ■ Areas where corrosion and thinning are likely to occur: "Contact points between pipes and supports" ■ Strengths of corrosion prevention measures using composite repair *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document explains "composite repair for through holes." It details how to determine the "lamination range" and "number of layers," as well as the leak-stopping effect of composite repair applied to a through hole (φ24mm), using images, diagrams, and tables for a thorough explanation. This is a useful reference, so please take a moment to read it. [Contents] ■ How to determine the "lamination range" and "number of layers" for composites (in the case of through holes) ■ Leak-stopping effect of composite repair applied to a through hole (φ24mm) *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The state of the 3B piping is broken, which is considered a missing part. We will consider repairs under the condition that the required durability of the equipment is 1 year, and we created two patterns of test specimens, conducting pressure tests on each. The required number of layers based on the design for a durability of 1 year is as follows: if we can achieve 7 layers with a 50mm overlap and 5 layers with a 150mm overlap, we demonstrated sufficient leak-stopping effect even under harsh construction conditions. [Verification Results] ■ Overlap 50mm - Number of layers: 7 - Result (MPa): 3.0 (leakage occurred at 3.0MPa during pressurization) ■ Overlap 150mm - Number of layers: 5 - Result (MPa): 5.0 (no leakage at 5.0MPa) * Testing was concluded at 5.0MPa due to the risk of piping breakage. * For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We examined the leak prevention effect when applying primer to stainless steel piping. A pressure test was conducted under the same conditions to compare the leak prevention effects of carbon steel piping and stainless steel piping. It was found that applying primer to stainless steel piping, which cannot undergo surface treatment with electric tools (Bristol Blaster), can demonstrate leak prevention effects. 【Test Piece Details】 ■ Shape: Connecting 1B piping only with a composite layer (PE sheet used for shaping) ■ Number of Layers: 2 layers ■ Surface Treatment ・ Carbon Steel Piping: Electric tools ・ Stainless Steel Piping: Primer *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document introduces the epoxy resin necessary for pipe repairs. It provides a detailed explanation of Phamanite's epoxy resin, mixing, and UV protection. This is a useful reference, so please take a moment to read it. 【Contents】 ■ What is epoxy resin? ■ Phamanite's epoxy resin ■ Mixing epoxy resin ■ UV protection for resin *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

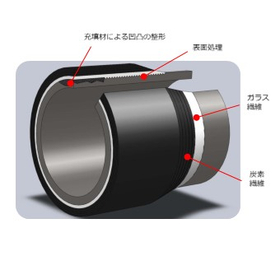

This document introduces carbon fiber composites necessary for pipe repairs. It provides a detailed explanation of the usage of carbon fiber in Firmonite, including four-directional fibers and thickness, using diagrams. This is a useful reference, so please take a moment to read it. 【Contents】 ■ About carbon fiber ■ Carbon fiber used in Firmonite ■ Four-directional fibers ■ Thickness of carbon fiber *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the construction achievements of Farmers at a geothermal power plant. At a certain geothermal power plant, while attempting to close a valve, it was discovered that more than five valves were stuck. All the stuck valves identified this time were gate valves. The fluid was steam, with a pressure of 0.02 MPa and a temperature of 102°C. After the work, we completed a total of five tasks in two days and were able to release all the stuck valves. [Case Summary] ■ Issues - While attempting to close the valves, it was discovered that more than five valves were stuck. - We wanted to avoid an emergency shutdown of the geothermal power plant due to valve disassembly and maintenance. ■ Solution - We completed a total of five tasks in two days and were able to release all the stuck valves. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Here is a case study of our product. During regular maintenance of the boiler, a valve was closed, and when it was time to reopen it towards the end of the repair, it became stuck. Since there was not enough time to arrange for a replacement or alternative work, we decided to try our product. The valve in question has a horizontally extending stem. To prevent the VRT from falling, it was securely fixed, and vibrations were applied to the stuck valve using a linear motion vibrator. We successfully released the stuck valve in 0.5 hours, making it operable again. 【Gate Valve】 ■ Size: 6B ■ Pressure: 1.6MPa ■ Fluid: Steam ■ Temperature: Approximately 200℃ *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Introducing the "Rotational Motion Vibrator" used in pharmacies. By using weights to create an eccentric turbine that rotates at high speed with air, vibrations are generated. These vibrations shake the stem, creating a slight gap in the screw thread and valve guide, allowing rust and dust to be moved and resolving any sticking. 【Features】 - The eccentric turbine rotates at high speed with air, generating vibrations. - Creates a slight gap in the screw thread and valve guide, moving rust and dust to resolve sticking. - The turbine rotates at high speeds of approximately 12,000 rpm to 17,000 rpm, depending on air pressure. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Introducing the "Linear Motion Vibrator" used in pharmacies. It generates vibrations by moving a piston up and down with air pressure. The vibrations strike the disk area, removing the causes of adhesion. The piston weighs 800g and reciprocates approximately 2,900 to 4,000 times per minute, depending on the air pressure. 【Features】 - Generates vibrations by moving the piston up and down with air. - Strikes the disk area with vibrations to remove the causes of adhesion. - The piston weighs 800g and reciprocates approximately 2,900 to 4,000 times per minute, depending on the air pressure. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In this document, we have published the performance data of Pharmice. Regarding construction achievements, we will introduce specific data on the types of valves and fluids. Additionally, we have summarized the benefits of Pharmice and the records of openings, so please take a moment to read through it. 【Contents】 ■ What is Pharmice ■ Benefits of Pharmice ■ Data on construction achievements ■ Summary of opening records *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document provides an explanation of Farmers. It details the mechanisms and benefits, the types of vibration units, and how to differentiate their use, with diagrams and images for clarity. This is a useful reference when selecting products, so please take a moment to read it. 【Contents】 ■ What are Farmers? ■ Benefits of Farmers ■ Mechanism of Farmers ■ Types of Vibration Units and Their Differentiation *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document introduces the fluids that can be handled with leak seals. It includes a table of major fluids with proven results. Additionally, it features images and results for valve flanges (wire/clamp method) and valves (box method). This is a useful reference, so please take a moment to read it. [Contents] ■ Fluids that can be handled ■ Results for valve flanges (wire method) ■ Results for valve flanges (clamp method) ■ Results for valves (box method) *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Pharmaize" is a repair technology that safely releases valves that have become stuck and cannot be operated. Are you resigned to breaking the valve by attempting to use brute force with tools like a Wilkie or hammer, or accepting the downtime and production loss associated with disassembly and replacement? With our "Pharmaize," you can solve stuck valve issues with low risk and while the equipment is operational, eliminating the need for disassembly! **Benefits of Pharmaize:** - No need to disassemble the valve; repairs can be made while the equipment is running. - Low risk as no excessive force is applied to the valve. - No restrictions on valve type, fluid, pressure, or temperature. *Currently offering case studies and performance data!* - **Case Study (1)**: A valve severely corroded from condensation and aging was released in about 2 hours. - **Case Study (2)**: A valve located in a confined space requiring auxiliary work for workspace could be serviced without additional construction. - **Performance Data**: An introduction to our past release achievements. *For more details, please refer to the materials or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The composite repair service provided by Fujifilm Pharma Night allows for the repair of reduced-thickness piping through the lamination and repair of composite materials made from carbon fiber and epoxy resin, enabling corrosion prevention, strength restoration, and leak sealing. Strength calculation in composite repair refers to the process of calculating the necessary thickness of composite layers required for repair, taking into account the purpose and conditions of the repair. Based on information from customers and on-site surveys, our company selects appropriate formulas tailored to the damage shape and calculates the "necessary composite thickness." 【What is strength calculation?】 ■ Calculating the thickness of composite layers required for repair, considering the purpose and conditions of the repair (design life, pipe diameter, pressure, temperature, fluid, etc.) ■ When performing strength calculations for the thickness of composite layers that exhibit leak-sealing effects, selecting the appropriate formula from multiple patterns. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Corrosion occurred on the 8B piping laid on the upper part of the tank in the oil refining plant, and according to the RT results, it was found that the minimum wall thickness of the 3/4B boss section is 0.6mm. In the event of a problem with the piping, there is a risk of leakage of the internal fluid (butane), and to update the piping, the entire plant must be stopped, making corrosion prevention measures essential before any leakage occurs. Therefore, as a corrosion prevention measure centered around the boss section, a composite was laminated in two layers over a range of 300mm to the left and right of the 8B main pipe. The high environmental barrier effect of the composite layer completely prevents the progression of external corrosion and reduces the risk of leakage compared to measures taken with just anti-corrosion paint. [Effects] ■ The high environmental barrier effect of the composite layer completely prevents the progression of external corrosion. ■ The risk of leakage is reduced compared to measures taken with just anti-corrosion paint. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Fujifilm Pharmanight, we provide leak seal repairs using our unique technology called the "Pharmanight Method" to seal leaks from components such as valves, flanges, piping, and the decks of floating roof tanks that make up plant equipment. Our technology is compatible with various fluids (steam, air, water, oil, gas, chemicals) and can address a wide range of leakage issues. We are currently offering materials that introduce repair methods for specific leakage points. 【Features】 ■ Sealant (compound) is selected appropriately based on fluid, pressure, and temperature (resistance confirmed for 1,500 types of fluids) ■ Avoid losses due to plant shutdowns and delays in product delivery ■ Adopted in petroleum refining, chemicals, power generation, steelmaking, food processing, incineration plants, etc. ■ 60,000 construction achievements in Japan over 40 years *Please refer to the catalog download for materials introducing repair methods for specific leakage points.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Due to the low temperature of the fluid, not only is there severe external corrosion from condensation, but also, since it has been 30 years since installation, there is significant aging deterioration. We would like to present a case of valve unseizing. After conducting the unseizing with "Pharmaise," we successfully unseized the valve in approximately 2 hours, making it operable. **Benefits of Pharmaise:** - No disassembly required, allowing repairs while the equipment is in operation. - Low risk as no excessive force is applied to the valve. - No restrictions on valve type, fluid, pressure, or temperature. *For more details on the Pharmaise method, please refer to the PDF materials or feel free to contact us.* *You can also view multiple documents showcasing case studies.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Resin Patch Method" is a technique that uses a special sealing material that maintains flexibility even after fully curing. No need to drain the contents of the tank. Even if the deck warps due to buoyancy or wind, it will follow the movement. It provides a leak-stopping effect for an extended period, with a warranty period of one year. 【Features】 ■ No need to drain the contents of the tank ■ Uses a special sealing material that maintains flexibility even after fully curing ■ Follows movement even if the deck warps due to buoyancy or wind ■ Provides a long-lasting leak-stopping effect (1-year warranty) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "T597/FSC-12F" is a sealing material used in the "resin patch method," which is specialized for leaks from the deck of floating roof tanks. "T597" is a polyurethane resin developed by our company, designed to have no foaming and to possess rubber-like flexibility. It has a high viscosity, can be applied thickly, and can be coated without flowing off even on uneven weld seams. "FSC-12F" is an overcoat agent made from the polyurethane resin developed by our company. Its viscosity has been reduced to a level that allows for application with a brush. 【Features】 ■ Used for leak repairs from the deck of floating roof tanks with the "resin patch method" ■ Maintains rubber-like softness even after curing ■ Suitable for leak repairs from areas affected by buoyancy or wind distortion and movement on the deck of floating roof tanks *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to a case where a "fire hydrant valve" necessary for supplying water for firefighting activities within the plant was found to be stuck during a fire incident. We immediately attempted to open the valve, but since it was connected to buried piping and installed in a narrow pit, the work was challenging. We concluded that updating the valve would require dismantling the pit, which was expected to lead to extended construction time and additional costs due to extensive ancillary work, prompting us to reconsider the update plan. Therefore, we adopted the "Pharmize" method, which not only eliminated the need for valve replacement but also allowed for work in confined spaces without the need for dismantling or ancillary construction. We successfully released the stuck valve in just "6.5 hours," making it operable. *For details on the Pharmize method, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Here is an introduction to a construction case study at a thermal power plant. Galvanic corrosion occurred due to the welding of dissimilar metals in the fire hydrant piping. Thinning progressed near the weld line, resulting in a state of penetration and leakage. Our company designed under the condition that "the target piping can be used for 20 years without replacement." When calculating the strength assuming that thinning progresses and the entire circumference of the weld line breaks, it was found that a composite of 15 layers is necessary to suppress leakage. Due to the composite layers, the fracture mechanism changes, which reduces the risk of pipe rupture and helps avoid human casualties and unexpected shutdowns of the power plant. **Strengths of Composite Repair** - Design can be tailored to purposes such as strength restoration, leak prevention, and corrosion protection (strength calculations). - Preventive maintenance measures for thinning piping with predictable service life. - Strength restoration and leak prevention with a maximum design life of 20 years are possible. - Design and construction comply with ISO 24817. - Quality that has passed performance tests by third-party organizations. *For more details on this method, "Composite Repair Service," please refer to the PDF materials or feel free to contact us. We also encourage you to check out the case study materials.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study from a petroleum refining plant. Rainwater entered the 2B dummy pipe support welded to the 3B elbow inside the petroleum refining plant, leading to corrosion over time and noticeable wall thinning. Therefore, we designed it under the condition of "being usable for 10 years without replacing the target piping" and decided to laminate a composite four-layer structure. The composite layers prevent the progression of permanent corrosion and also consider the future leak-stopping effect in case the thinned areas penetrate within the design lifespan (10 years). 【Strengths of Composite Repair】 ■ Design can be tailored to purposes such as strength restoration, leak stopping, and corrosion prevention (strength calculations) ■ Preventive maintenance measures for thinned piping with predictable service life ■ Strength restoration and leak stopping with a maximum design life of 20 years are possible ■ Design and construction in accordance with ISO 24817 ■ Quality that has passed performance tests by third-party organizations *For more details on this method, "Composite Repair Service," please refer to the PDF materials or feel free to contact us. *We also encourage you to check out the case study materials.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Fujifilm Pharma Night, we provide leak seal repairs using our unique technology called "Pharma Night Method" to seal leaks from components such as valves, flanges, piping, and floating roof tank decks that make up plant equipment. Our technology is compatible with various fluids (steam, air, water, oil, gas, chemicals) and can address a wide range of leakage issues. We are currently offering materials that introduce repair methods for each leakage point. (Please check the PDF download for details.) 【Features】 - Sealant (compound) is selected based on the appropriate fluid, pressure, and temperature (with resistance confirmed for 1,500 types of fluids). - Avoid losses due to plant shutdowns and delays in product delivery. - Adopted in oil refining, chemicals, power generation, steelmaking, food, incineration plants, etc. - 55,000 domestic construction achievements over 40 years. *For details on each repair method, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Composite Repair" is a preventive maintenance measure for reduced-thickness piping that complies with the international standard ISO 24817. Through strength calculations, the optimal repair range and number of layers are determined based on the required service life and purpose. High-quality materials with a maximum design life of 20 years are used, and construction is carried out under thorough management. By repairing with composite "before penetration," the service life can be predicted, thereby avoiding the risk of unexpected equipment shutdowns due to pipe breaks caused by external corrosion. This not only reduces production losses from leaks at penetration points but also facilitates long-term equipment renewal planning after repairs. 【Strengths of Composite Repair】 ■ Design can be tailored to purposes such as strength restoration, leak prevention, and corrosion protection (strength calculations) ■ Preventive maintenance measure for reduced-thickness piping with predictable service life ■ Strength restoration and leak prevention possible with a maximum design life of 20 years ■ Design and construction compliant with ISO 24817 ■ Quality that has passed performance tests by third-party organizations *You can view case studies of construction in thermal power plants and oil refining plants, as well as proposal materials tailored to the purpose of repairs, from the "PDF Download" section. Please feel free to contact us with any inquiries.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our valve release service "Pharmaize" allows for low-risk operation without the need for disassembly maintenance. It is commonly said that troubles caused by valve sticking tend to occur in lines with low usage frequency. When we talk about sticking, there are various cases such as: ◎ Not closing when fully open ◎ Not opening when fully closed ◎ Getting stuck partway through operation... In such situations, have you ever tried using brute force with tools like a Wilkie or hammer, only to end up breaking the valve? Or have you resigned yourself to the inevitable line stoppage for disassembly maintenance or replacement, along with the associated production losses? With our service, you can resolve these troubles without worry! 【Benefits of Pharmaize】 ■ No need to disassemble the valve, allowing for repairs while the equipment is in operation ■ Low risk as no excessive force is applied to the valve ■ No restrictions on valve type, fluid, pressure, or temperature *We are currently offering case study materials! - A valve suffering from severe external corrosion due to condensation and aging was released from sticking in about 2 hours - Even challenging work in confined spaces was resolved without dismantling or additional construction *For more details, please refer to the materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

If you are having trouble with "leakage issues from the valve gland," please feel free to consult us! 【How to stop leakage from the valve gland while the plant is in operation?】 Gland leakage in valves occurs due to wear from long-term use, thermal history, etc., which leads to the deterioration of the gland packing. Our "Valve Gland Method" features the injection of sealing material into the deteriorated gland packing area, which stops the leakage while allowing the valve to continue operating. 【Features of the construction】 ■ Work can be done while the plant is in operation, avoiding economic losses and delays in delivery associated with equipment shutdown. ■ The work can be completed on the same day! ■ The valve can still be operated after the leakage has been stopped. ■ Handle operation and tightening can be performed. *For more details, please download and view the PDF materials.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

If you are having trouble with "leakage issues from piping fittings and welds," please feel free to consult us! 【How to stop leaks from pipes, fittings, and welds while the plant is in operation?】 Leaks from pipes, fittings, and welds are different from valve glands and flanges that can be addressed by tightening bolts. In pipes, high-pressure steam can erode the area around the piping, and it is not uncommon for leaks to gradually expand. Our "Box Method" features a two-part structure for the jig (box, clamp), allowing it to be installed around the leak point in the piping, enabling safe leakage prevention while maintaining operational status. 【Features of the construction】 ■ Can accommodate a wide range of conditions. ■ Avoids economic losses and delays in delivery associated with equipment shutdowns. ■ By installing a double-pipe structure box around the leak point, it can safely stop the leakage. ■ Effective as preventive maintenance against breakage at thinned areas. *For more details, please download and view the PDF materials.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

If you are having trouble with "leakage issues from flanges," please feel free to consult us! 【How to stop leakage from flanges while the plant is in operation?】 Flanges are used to connect pipes, but if leakage occurs due to gasket deterioration, replacing the gasket while continuing operation is very difficult. Our "clamp method" can be applied even when there is a wide gap between flanges or when the bolt strength is insufficient. This helps avoid economic losses and delays in delivery associated with equipment shutdown. 【Features of the construction】 ■ It can handle wide gaps between flanges and high fluid pressure. ■ It helps avoid economic losses and delays in delivery associated with equipment shutdown. ■ The sealing material has no adhesive properties, making disassembly and maintenance easy. ■ No drilling is required, allowing for the reuse of flanges. *For more details, please download and view the PDF materials.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

If you are having trouble with "leakage issues from flanges," please feel free to consult us! 【How to stop leakage from flanges while the plant is in operation?】 Flanges are used to connect pipes, but if leakage occurs due to gasket deterioration, it is very difficult to replace the gasket while continuing operation. Our "Wire Method" allows work to be done while the plant is in operation. Moreover, the work can be completed on the same day! This helps avoid economic losses and delays in delivery associated with equipment shutdown. 【Features of the construction】 ■ Work can be done while the equipment is operating. ■ Same-day completion of work! ■ Avoid economic losses and delays in delivery associated with equipment shutdown. (Construction conditions: flange gap of about 7mm, non-combustible fluid, pressure of 4.0MPa, temperature below 350℃) *For more details, please download and view the PDF materials.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document introduces the long-term extension of reduced meat piping provided by Fujifarma Night, titled "Composite Repair." It includes information on "design," "quality," and "construction" in accordance with ISO standards. Our service can also provide a [design assessment] that outlines design conditions and durability years, which can be useful for your plant maintenance plan after the composite repair work. Please contact us if you require our services. [Contents (excerpt)] ■ "Design" in accordance with ISO standards ■ "Quality" in accordance with ISO standards ■ "Construction" in accordance with ISO standards *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document introduces how much strength can be restored by the "Composite Repair" provided by Fujifarma Night for the long-term extension of reduced meat piping. Our service is effective as a reliable preventive maintenance because it allows for design considerations based on strength calculations. Please contact us if you require our services. [Contents] ■ Introduction: "What can be done with Composite Repair" ■ Verification of how much strength can be restored with Composite Repair *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document introduces the corrosion protection and leak prevention measures of the long-term extension of reduced meat piping provided by Fujifarma Night, titled "Composite Repair." It includes sections on "What can be done with Composite Repair" and "Examples of Composite Repair applications." Our service can be designed according to the customer's repair objectives, defect shapes, required durability years, and other conditions, allowing us to propose suitable repairs for our customers. Please contact us if you require our services. [Contents] ■ Introduction: "What can be done with Composite Repair" ■ Composite Repair that considers not only corrosion protection but also leak prevention ■ We will introduce examples of Composite Repair that provide both corrosion protection and leak prevention effects! *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Tank roof repair can be performed during storage as it does not require welding work. It uses a special repair material that maintains flexibility even after curing. It is suitable for leaks from decks with movement that cannot be adequately followed by iron cement or hardening putty. 【Features】 ■ Construction during storage - Can be applied while the contents are still stored. ■ Follows deck distortion - Can follow the distortion of the deck without cracking, allowing for long-term leak prevention. ■ Strong adhesion - Can be applied over weld seams, vertical surfaces, areas with insufficient surface treatment, and temporary repairs made by customers, demonstrating excellent adhesion. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document contains information about the composites of Fuji Pharmanight Co., Ltd. It introduces topics such as "Design of Composite Repairs," "Quality of Composite Repairs," and "History of the Development of Composite Repairs." We encourage you to read it. 【Contents】 ■ What is Composite? ■ Design of Composite Repairs ■ Quality of Composite Repairs ■ History of the Development of Composite Repairs *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document introduces "Leak Seal," which means preventing leaks. Our company offers a "Leak Seal Service" that uses our unique technology called "Fermanite Method" to seal leaks from valves, flanges, and piping that make up plant equipment. This method allows repair work to be done while online, so there is no need to stop the plant. [Contents] ■ What is Leak Seal? ■ The principle of Leak Seal: "Fermanite Method" *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document presents the specifications of the leak seal service and compounds (seal materials) from Fuji Pharma Night. It introduces topics such as "the mechanism of leak sealing," "selection of compounds," and "variations of compounds." Please take a moment to read it. 【Contents】 ■ Mechanism of leak sealing ■ Variations of compounds ■ Selection of compounds ■ How to select compounds *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration