136~180 item / All 380 items

Displayed results

Filter by category

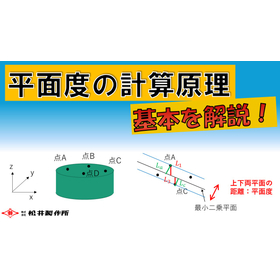

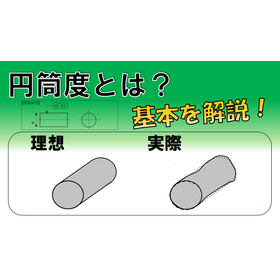

YouTube

This is an introduction to the videos published on our YouTube channel "Matsui Manufacturing Channel"!