大野精工 機工販売事業部

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF

大野精工 Company Profile

A locally-focused parts manufacturer that is growing at an unprecedented speed.

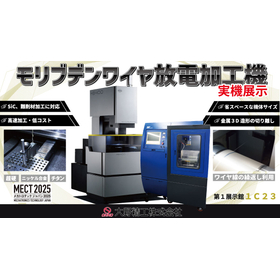

At Ohno Seiko Co., Ltd., we primarily offer sales of electrical discharge machines, mirror finish processing, and precision parts processing. 【Sales of Molybdenum Wire Electrical Discharge Machines】 We have a business partnership with Suzhou Sanguang Technology Co., Ltd. We are the exclusive domestic distributor for the "HB Series" of molybdenum wire electrical discharge machines. Please feel free to contact us for test processing and other inquiries. 【Sales of Original Jigs】 We sell the "PAD Series" of parallel jigs for wire cutting, utilizing patented technology. 【Others】 - Sales of pneumatic positioning jigs, among others. 【Precision Parts Processing】 In a temperature-controlled room maintained at 20℃±1℃, we possess the latest three-dimensional measuring machines (three units), shape measuring instruments, tool microscopes, surface roughness measuring instruments, and more. We continue to challenge the limits of ultra-mirror finish processing with an Rz of 0.2μm and ultra-precision processing. Please feel free to contact us for prototypes and other requests.

Business Activities

【Sales Items】 ■ Sales of discharge machining equipment ■ Sales of original jigs ■ Sales of overseas tools ■ Precision parts processing for automotive devices ■ Super mirror finish processing ■ Prototype production, etc.

Related Videos

Products/Services (48)

catalog(9)

Survey responses are required to view e-book details. Click to view the e-book.

![[Patent Granted] Parallel Alignment Jig for Wire Cutting | PAD Series | Ohno Seiko Co., Ltd. with Price](https://image.mono.ipros.com/public/catalog/image/01/393/700419/IPROS47991224122004692214.jpeg?w=120&h=170)

news(12)

Detailed information

| Company name | 大野精工 機工販売事業部 |

|---|---|

| number of employees | 110 |

| Contact address | postalcode 445-0012 Aichi/ Nishio-shi/ 35-1 Shitahanezumi-choView on map TEL:0563-75-1138 FAX:0563-75-3966 |

| Key Partners | Toyota Motor Corporation, Denso Corporation, Nidec Corporation, Misumi, Disco, approximately 200 business partners centered around Toyota-affiliated suppliers. Affiliated companies Materials-related: 12 companies Processing-related: 125 companies Surface treatment and heat treatment-related: 63 companies |

| Business Locations | Click here for the list |

| Industry | Industrial Machinery |

大野精工 Building Image

大野精工 Building Image

![[MECT2025 Actual Machine Exhibition] Molybdenum Wire Electrical Discharge Machining Machine product image](https://image.mono.ipros.com/public/product/image/2065685/IPROS68013622882014238.jpg?w=280&h=280)

![[Catalog] Pneumatic Positioning Fixture for Machining 'ZERO-POINT SYSTEMS'](https://image.mono.ipros.com/public/catalog/image/01/a4f/660440/IPROS94126219560991276236.jpeg?w=120&h=170)