1~45 item / All 50 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~45 item / All 50 items

◆Master Gear Generally used as a master for engagement testing machines and tooth thickness comparison measurements during mass production processing. Our master gears can achieve high precision of JIS MO grade. ◆Vanishing Cutter Tapers the spline tooth direction after broaching. (Prevents gear disengagement) ◆Haas Coupling Used for high-precision angular division of machine tool tool holders and index tables, capable of divisions as small as 1°. ◆Product Detail Page https://www.nidec.com/jp/machine-tool/products/B702/M100/S111/NMTJ-Other-tools/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

It is classified into internal broaches used for automotive speed reducers and machine tools, and surface broaches for machining the outer surfaces of specially shaped parts used in turbine plate grooves of generators and jet engines, as well as various industrial machinery. Based on many years of experience and know-how, our company independently develops and manufactures a variety of broaches. We have numerous achievements that meet the required shapes and performance. ◆ Product details page https://www.nidec.com/jp/machine-tool/products/B702/M100/S103/NMTJ-broach/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◆Chamfering Tool for Cutting Surfaces - The dedicated chamfering tool is a tool uniquely developed by our company for chamfering processing. - By using tool design simulation, we create a custom design for each workpiece, achieving the optimal chamfer shape. - Like standard gear cutters, it allows for re-sharpening and recoating, reducing running costs. ◆Processing Principle - We use dedicated chamfering tools that are customized for each workpiece through simulation software. - Chamfering is performed by executing a generating motion similar to hob processing on the end face of the workpiece. ◆Product Detail Page https://www.nidec.com/jp/machine-tool/products/B702/M100/S110/NMTJ-chamfer_tool/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◆ Super Coat Shaving - Surface hardness is 1.5 times that of high-speed steel, improving wear resistance. - Hardened layer of 0.1 to 0.2 mm. Surface condition remains almost unchanged. ◆ High Hardness High-Speed Steel MACH3 - Increased amounts of V and Co effective against wear, and refined and dispersed carbides to improve toughness (chipping resistance). - By leveling and dispersing carbides, achieves high hardness while maintaining grinding performance comparable to conventional materials. ◆ Fine Pitch Shaving - By reducing the spacing of the serration pitch compared to the standard, surface roughness of the tooth face is improved. - Optimal pitch size determined by unique design simulation enhances tooth profile precision. ◆ Product Details Page https://www.nidec.com/jp/machine-tool/products/B702/M100/S102/NMTJ-shaving_cutter/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◆ High-precision finishing enables shaving-free processing ◆ Increased efficiency leads to improved productivity ◆ Tool life is 2 to 5 times longer (compared to conventional TiN wet cutting), resulting in cost reduction ◆ Improved working environment due to the absence of cutting oil ◆ Product detail page https://www.nidec.com/jp/machine-tool/products/B702/M100/S101/NMTJ-pinion_cutter/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◆Adopts a coating film with excellent wear resistance (film hardness Hv4,000), achieving an extended lifespan. ◆Compatible with a wide range of processing areas (high-speed steel hobs, carbide hobs). ◆Demonstrates performance in both dry and wet processing, in any cutting environment. ◆Product details page https://www.nidec.com/jp/machine-tool/products/B702/M100/S100/NMTJ-hob/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◆Realization of High-Precision Machining - We have adopted a cast iron bed with excellent damping properties, and the grinding wheel shaft is driven by a high-rigidity spindle unit using high-precision angular ball bearings, directly connected to a flat motor. - Our traction drive reducer is used for the cutter shaft, achieving extremely smooth rotation without harmful vibrations. ◆High-Precision Machining of Arbitrary Tooth Shapes - Full CNC control of all axes with a resolution of 0.1 microns has been realized. ◆Reduction of Setup Time and Trial Cutting Adjustment Time - For initial products: Setup calculations and changes are executed via CNC by inputting the necessary data. - For repeat products: Setup changes are completed instantly by simply calling up and activating the data. ◆Complete Skill-Free Operation with CNC Experience, intuition, and techniques previously required for traditional tooth cutting operations are no longer necessary. ◆Product Detail Page https://www.nidec.com/jp/machine-tool/products/B700/M104/S105/NMTJ-za30a/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Utilizing the know-how gained from manufacturing machine tools that produce products active in various industrial fields, we are capable of processing all large gears used in construction machinery and wind turbines.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◆High-efficiency grinding using barrel-shaped threaded grinding wheels (generative grinding process) By adopting barrel-shaped threaded grinding wheels, a larger axis intersection angle is achieved, increasing the grinding speed (slip speed) → Improved cutting performance = high tooth surface correction capability (pitch accuracy also improved) → Improved grinding ratio = extended grinding wheel life (reduced tool costs) ◆Generative grinding through high-speed, high-precision synchronous rotation of the grinding wheel axis and workpiece axis ◆Product detail page https://www.nidec.com/jp/machine-tool/products/B700/M104/S104/NMTJ-zi20a/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◆ Capable of creation grinding and molding search processing - High-precision processing of a wide variety of workpieces - Supports small lot production with easier setup - Improved operability and maintainability - Fully automatic machine with 9-axis NC control - Enhanced dressing function - Equipped with on-machine measurement device (optional) - Achieves space-saving design ◆ Product detail page https://www.nidec.com/jp/machine-tool/products/B700/M104/S104/NMTJ-ze-series/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◆High-Precision Machining with ZE16C/ZE26C - The newly designed grinding wheel spindle improves static rigidity by 50% and dynamic rigidity by 35%. - Equipped with our linear scale as standard, achieving long-term precision stability. ◆High-Efficiency Machining with ZE16C/ZE26C - Significantly increased the rotation speed of the built-in motor type grinding wheel spindle and table. - Simultaneous shift grinding of both tooth surfaces is possible. - Enhanced the speed of the tooth alignment mechanism and ring loader, achieving a non-processing time of 6 seconds (for round workpieces). - Expanded the grinding wheel width by 28% to 160mm, extending the dressing interval. ◆Product Detail Page https://www.nidec.com/jp/machine-tool/products/B700/M104/S104/NMTJ-ze-series/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◆High-end machines with high rigidity that achieve high productivity Equipped with a high-power synchronous built-in spindle motor, we have thoroughly pursued machine rigidity. - The linear three axes utilize a highly damped sliding guide surface. - The spindle and table axes use a high-power synchronous built-in spindle motor. - Super skiving allows for the dispersion of chips, enabling efficient processing with fewer passes. ◆"Super Skiving System" that combines our unique tools and machines, achieving outstanding tool life Through collaboration with our unique tool (Super Skiving Cutter), we propose the best solution for internal gear machining. Using the Super Skiving Cutter, a significant increase in tool life compared to conventional pinion cutters can be expected. ◆Product details page https://www.nidec.com/jp/machine-tool/products/B700/M104/S102/NMTJ-mss300/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◆Support for High-Precision Machining (SE25FR, SC40FR) By adopting high-precision worm gears for the cutter head and table, we achieve high-precision machining by suppressing rotational fluctuations. ◆Product Detail Page https://www.nidec.com/jp/machine-tool/products/B700/M104/S101/NMTJ-se25fr_sc40fr/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◆ Helical Guide-less No need for guide replacement; set any twist angle in the NC program to process helical gears. ◆ NC Relieving Mechanism (ST40A Option) Automates the relieving operation with NC, allowing for arc-shaped crowning and taper processing (up to ±0.3 degrees) through program operation. ◆ Product Detail Page https://www.nidec.com/jp/machine-tool/products/B700/M104/S101/NMTJ-st_series/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By leveraging the know-how gained from manufacturing machine tools that produce products active in various industrial fields, we are capable of processing all large gears used in construction machinery and wind turbines.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◆Excellent Machining Precision Based on a high-rigidity and high-precision mechanical structure for the table, sliding surfaces, and feed shafts, we pursue high precision in machining from all aspects, including improvements in positioning accuracy and reductions in the effects of thermal displacement. The S series achieves JIS Grade 5 [JIS B1702 (1998)] with high-precision gears (spur gears). Additionally, we guarantee a repeat machining accuracy of Cp=1.33 against an overball diameter tolerance of 50μm (with thermal displacement correction device included). We meet the needs for high precision and respond to demanding orders with reliable quality. ◆Stable Quality Through thorough measures against thermal deformation, we maintain stable machining quality. Dimensional changes in the workpiece during machining are caused by mechanical thermal deformation due to cutting oil heated by machining heat coming into contact with the bed surface. In response, we circulate coolant within the bed to equalize the thermal distribution and minimize thermal deformation. ◆Product Detail Page https://www.nidec.com/jp/machine-tool/products/B700/M104/S101/NMTJ-s-series/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◆Excellent Machining Precision Based on a high-rigidity and high-precision mechanical structure for the table, sliding surfaces, and feed shafts, we pursue high precision in machining from all aspects, including improving positioning accuracy and reducing the effects of thermal displacement. The S series achieves JIS Grade 5 [JIS B1702 (1998)] with high-precision gears (spur gears). Additionally, we guarantee a repeat machining accuracy of Cp=1.33 against an overball diameter tolerance of 50μm (with thermal displacement correction device included). We meet the demands for high precision and respond to stringent orders with reliable quality. ◆Stable Quality Thorough measures against thermal deformation ensure stable machining quality. Dimensional changes in the workpiece are caused by thermal deformation of the machine due to cutting oil heated by machining heat coming into contact with the bed surface. In response, we circulate coolant within the bed to equalize the thermal distribution and minimize thermal deformation. ◆Product Detail Page https://www.nidec.com/jp/machine-tool/products/B700/M104/S101/NMTJ-s-series/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◆Fully compatible with dry cutting ◆Modularization of transport devices for easy line configuration The modularization of peripheral and transport devices allows for easy line configuration and layout changes. As a result, it has become possible to minimize the setup time. We have prepared two types of configurations that can be selected based on the work style. Type 1: Front flat type, optimal for manual workpiece loading machines Type 2: Narrow opening type, optimal for automation compatibility ◆Product details page https://www.nidec.com/jp/machine-tool/products/B700/M104/S101/NMTJ-se_series/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◆High-speed and high-precision chamfering method - By performing chamfering on the gear's chamfered area with a dedicated chamfering tool, we can achieve a good surface finish quality without bulging in the end face or tooth face direction and without secondary burrs, all within a short cycle time. - We can also simultaneously remove end face burrs generated during the previous hob machining process. - Accurate simulations ensure that the desired chamfer shape is achieved. Machining of the root area and large chamfer widths of over 1mm are also possible. ◆Automation applications We offer automation packages tailored to your production style. ◆Dedicated chamfering tool The dedicated chamfering tool is a uniquely developed tool for cutting chamfering operations. For more details, click here >> https://www.nidec.com/jp/machine-tool/products/B702/M100/S110/NMTJ-chamfer_tool/ ◆Product detail page https://www.nidec.com/jp/machine-tool/products/B700/M104/S107/NMTJ-cf26a/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◆GE15HS: Pursuing high-efficiency processing of mass-produced gears for automobiles and motorcycles "GE15HS" is suitable for high-speed light cutting processing of gears for automobiles and motorcycles. The direct-drive high-speed spindle enables the machining of high-precision gears in a short cycle time. ◆GE25HS: High-speed high-power spindle accommodating a wide range of machining areas "GE25HS" is suitable for mass production processing of automotive gears, including differential gears. The powerful spindle motor and high-speed rotating table achieve high-efficiency processing. ◆Product details page https://www.nidec.com/jp/machine-tool/products/B700/M104/S100/NMTJ-gehs_series/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◆ Direct drive adopted for the hob spindle and table, reducing pitch error by 80% compared to conventional methods. - High-speed spindle enables efficient machining with small-diameter hob cutters. The direct drive reduces spindle vibration and heat generation associated with increased rotation, achieving high precision. - The configuration takes into account the table rotation accuracy, which affects workpiece precision, enabling high-precision machining. ◆ Product details page https://www.nidec.com/jp/machine-tool/products/B700/M104/S100/NMTJ-gefr_series/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◆Supports the processing of all large gears used in construction machinery and wind turbines Utilizing the know-how gained from manufacturing machine tools that produce products active in various industrial fields, we are capable of processing all large gears used in construction machinery and wind turbines. ◆Product detail page https://www.nidec.com/jp/machine-tool/products/B700/M104/S106/NMTJ-largegear/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◆Excellent Machining Accuracy Based on a high-rigidity and high-precision mechanical structure for components such as the table, sliding surfaces, and feed shafts, we pursue high precision in machining from all aspects, including improving positioning accuracy and reducing the effects of thermal displacement. The G series achieves JIS Class 3 for high-precision gears and JIS Class 5 for mass-produced gears [JIS B 1702 (1998)]. Additionally, we guarantee a repeatability machining accuracy of Cp=1.33 against a tolerance of 50μm for the overball diameter, meeting high precision needs. ◆Thorough Measures Against Thermal Deformation to Maintain Stable Machining Quality Dimensional changes in the workpiece during machining are caused by thermal deformation of the machine due to cutting oil heated by machining heat coming into contact with the bed surface. To address this, we circulate coolant within the bed to equalize the thermal distribution and minimize thermal deformation. ◆Product Detail Page https://www.nidec.com/jp/machine-tool/products/B700/M104/S100/NMTJ-g_series/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◆Excellent Machining Precision Based on a high-rigidity and high-precision mechanical structure for components such as the table, sliding surfaces, and feed shafts, we pursue high precision in machining from all aspects, including improving positioning accuracy and reducing the effects of thermal displacement. The G series achieves JIS Class 3 for high-precision gears and JIS Class 5 for mass-produced gears [JIS B 1702 (1998)]. Additionally, the repeatability machining accuracy guarantees Cp=1.33 for an overball diameter tolerance of 50μm, meeting high precision needs. ◆Thorough Measures Against Thermal Deformation to Maintain Stable Machining Quality Dimensional changes in the workpiece during machining are caused by thermal deformation of the machine due to cutting oil heated by machining heat coming into contact with the bed surface. In response, circulating coolant within the bed equalizes the thermal distribution and minimizes thermal deformation. ◆Product Detail Page https://www.nidec.com/jp/machine-tool/products/B700/M104/S100/NMTJ-g_series/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◆Excellent Machining Precision Based on a high-rigidity and high-precision mechanical structure for components such as the table, sliding surfaces, and feed shafts, we pursue high precision in machining from all aspects, including improving positioning accuracy and reducing the effects of thermal displacement. The G series achieves JIS Class 3 for high-precision gears and JIS Class 5 for mass-produced gears [JIS B 1702 (1998)]. Additionally, we guarantee a repeatability machining accuracy of Cp=1.33 for a ball diameter tolerance of 50μm, meeting high precision needs. ◆Thorough Measures Against Thermal Deformation to Maintain Stable Machining Quality Dimensional changes in the workpiece during machining are caused by thermal deformation of the machine due to cutting oil heated by machining heat coming into contact with the bed surface. In response, we circulate coolant within the bed to equalize heat distribution and minimize thermal deformation. ◆Product Detail Page https://www.nidec.com/jp/machine-tool/products/B700/M104/S100/NMTJ-g_series/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◆Fully compatible with dry cutting ◆Modularization of peripheral devices for easy line configuration The modularization of peripheral and transport devices allows for easy line configuration and layout changes. As a result, it has become possible to minimize setup changeover time. We offer two types: Type 1, which is square-shaped, and Type 2, which has a narrow opening for easy line integration. ◆Product details page https://www.nidec.com/jp/machine-tool/products/B700/M104/S100/NMTJ-ge_series/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Aerospace Field Simultaneous 5-Axis Control Planomill MVR30S-5H High-Power Spindle for Fast 5-Axis Machining This single machine can process aerospace aluminum parts from rough machining to finishing. With a high-speed and high-power spindle and simultaneous 5-axis control, it achieves reliable and efficient machining. Additionally, it features a large table that can easily accommodate large parts and options that leverage the know-how unique to aircraft manufacturers, effectively meeting the needs of aerospace component machining. Heating Field Side Entry Blade Groove Machining Machine High-Efficiency Machining with Four Heads It processes the blade grooves of turbine rotors using special cutters. Construction Machinery Field Large Frame Machining Machine All-Around Machining with One Chucking It aims to efficiently process box-shaped or long workpieces. ◆ For product details, visit here https://www.nidec.com/jp/machine-tool/products/B700/M106/S100/NMTJ-dedicated_manual_training_machine/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Stable processing that meets diverse machining needs High precision and high rigidity of mechanical structures such as the main spindle and feed axis, along with a minimum command unit of φ0.1μm for feed control, achieve high machining accuracy. The repeat machining accuracy remains stable, even after a cold start, with a cylindrical change of φ3μm/50mm (RD23/RD32) after one hour. -RD23- Grinding wheel slide type Angular/Straight Swing (mm) φ230 Distance between centers (mm) 350 Maximum machining diameter (mm) φ150 Maximum grinding mass (kg) 80 -RD32- Grinding wheel slide type Angular/Straight Swing (mm) φ320 Distance between centers (mm) 500/1,000 Maximum machining diameter (mm) φ300 Maximum grinding mass (kg) 150 ◆ For product details, click here https://www.nidec.com/jp/machine-tool/products/B700/M105/S100/NMTJ-r_series/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◆High precision machining and stable quality ◆Skill-less operation and easy handling ◆High productivity ◆Easy adaptation to automation and line integration ◆High functionality and reliable safety ◆Ideal for palm-sized part machining -PD23- Grinding wheel slide type Angular/Straight Swing (mm) φ230 Distance between centers (mm) 350 Maximum machining diameter (mm) φ200 Maximum grinding mass (kg) 50 -PD32- Grinding wheel slide type Angular/Straight Swing (mm) φ320 Distance between centers (mm) 500/1,000/1,500 Maximum machining diameter (mm) φ300 Maximum grinding mass (kg) 150 ◆For product details, click here https://www.nidec.com/jp/machine-tool/products/B700/M105/S100/NMTJ-p_series/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

It is a high-speed cutting machine for precision molds, electrodes, and high-precision parts for IT, optics, medical devices, semiconductor devices, etc. In addition to its basic performance that maintains high precision for extended periods, the flexible automation-compatible layout concept enables effective utilization of floor space and automation equipment. In response to changes in the lowest point position of the tool, which directly affects machining accuracy, images of the rotating tool captured by LED lighting and a high-resolution CCD camera are digitally processed to automatically determine the stability of the lowest point position of the tool after thermal displacement has converged, allowing for tool length correction to be executed. 【Features】 - Our proprietary imaging-based tool measurement system - Achieves precision that cannot be reached through correction - Balances fine high precision with high efficiency - Ensures long-term high surface quality machining - Pursues 5-axis precision equivalent to that of a 3-axis machine -High-precision gantry machining center LH250- Movement (X × Y × Z axes) 2,500 × 1,000 × 600mm Maximum spindle speed 20,000 min-1 ◆ For product details, click here https://www.nidec.com/jp/machine-tool/products/B700/M101/S100/NMTJ-precision_machine/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

It is a high-speed cutting machine for precision molds, electrodes, and high-precision parts used in IT, optics, medical devices, semiconductor devices, etc. In addition to its basic performance that maintains high precision for extended periods, it realizes effective use of floor space and automation equipment through a flexible automation-compatible layout concept. In response to changes in the lowest point position of the tool, which directly affects processing accuracy, images of the rotating tool captured by LED lighting and a high-resolution CCD camera are digitally processed to automatically determine the stability of the lowest point position of the tool after thermal displacement has converged, executing tool length compensation. 【Features】 - Our unique imaging-based tool measurement system - Achieves precision that cannot be reached through compensation - Balances fine high precision with high efficiency - Ensures long-term high surface quality processing - Pursues 5-axis precision equivalent to that of a 3-axis machine - Precision Machining Machine μV5 - Movement range (X × Y × Z axes) 900 × 550 × 450 mm Maximum spindle speed 30,000 min-1 ◆ For product details, click here https://www.nidec.com/jp/machine-tool/products/B700/M101/S100/NMTJ-precision_machine/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a high-speed cutting machine for precision molds, electrodes, and high-precision parts used in IT, optics, medical devices, semiconductor devices, etc. In addition to its basic performance that maintains high precision for extended periods, it achieves effective use of floor space and automation equipment through a flexible automation-compatible layout concept. In response to changes in the position of the tool's lowest point, which directly affects machining accuracy, the images of the rotating tool captured by LED lighting and a high-resolution CCD camera are digitally processed to automatically determine the stability of the tool's lowest point position after thermal displacement has converged, allowing for tool length compensation to be executed. 【Features】 ■ Our proprietary imaging-based tool measurement system ■ Achieves precision that cannot be reached through compensation ■ Balances fine high precision with high efficiency ■ Ensures long-term high surface quality machining ■ Pursues 5-axis precision equivalent to that of a 3-axis machine -Compact Precision Machining Machine μV1-5X (5-axis machine)- Maximum workpiece size (mm) φ160 (with interference limitations) Maximum spindle speed 40,000 min-1 ◆ For product details, click here https://www.nidec.com/jp/machine-tool/products/B700/M101/S100/NMTJ-precision_machine/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Deep cuts can be made with high removal rates. ● The spindle rotates at a class-leading 4,000 min-1. With a maximum torque of 2,793 N-m (285 kgf-m) and a maximum output of 45 kW, this is a high-power machine. ● The spindle motor and reduction gearbox are located at the top of the ram. The spindle is driven by a two-stage variable helical gear. ● The cross rail movement is controlled by NC commands with an accuracy of 0.001 mm. It can be positioned at the optimal location for machining. ● Equipped with a large 400 mm square ram. Powerful cutting is possible with a robust ram measuring 400 mm on each side. ● The machine features a powerful spindle with a diameter of φ130 mm, supported by multi-row cylindrical roller bearings. Oil mist lubrication is used for the bearings, and cooling oil circulates around the outer circumference of the bearing housing. ◆ Product details page https://www.nidec.com/jp/machine-tool/products/B700/M102/S100/NMTJ-mvrdx-series/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Machine structure that eliminates heat, vibration, and misalignment 1) To eliminate deformation caused by saddle movement, the cross rail's cross-sectional area is increased to enhance rigidity. 1) By eliminating overhang, even slight vibrations during processing are not amplified. 2) Guides are also placed in the center to prevent deflection of the table when the workpiece is set. 2) The X-axis, which moves heavy workpieces, is made rigid with two ball screws, while also minimizing yawing of the table width. 3) A symmetrical structure has been adopted to prevent thermal deformation of the machine body. 3) A thermostat stabilizer column that is less affected by temperature changes has been used. 3) Forces generated during acceleration and deceleration, as well as cutting reaction forces, are firmly supported by a wide column and four-row guides (arranged on the front and inner sides of the double column). ◆Product details page https://www.nidec.com/jp/machine-tool/products/B700/M102/S100/NMTJ-mvrfx-series/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Outstanding Precision Suppresses thermal displacement of the spindle with spindle axis cooling ● Reduces step and bite on the machining surface ● Enables high-precision machining from low to high speeds Maintains geometric accuracy unaffected by changes in ambient temperature, Thermo Stabilizer Column ● Setup can be done without worrying about temperature changes over time ● Even during long machining, the origin remains stable, reducing the frequency of centering Commitment to Cutting Capability ● Powerful heavy cutting for both vertical and horizontal axes Versatile as Desired ● A rich lineup of attachments and selectable package options You can choose attachments according to shapes such as narrow areas, inclined surfaces, and free-form surfaces, as well as purposes like high-speed machining and high-precision machining. ◆ Product Detail Page https://www.nidec.com/jp/machine-tool/products/B700/M102/S100/NMTJ-mvrhx/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Pursuit of High Productivity Shortening non-cutting time with speedy axis rapid feed rates Commitment to Cutting Capability ● Powerful five-sided machining with high-performance spindle and attachments ● Gear Drive spindle lineup, ideal for heavy cutting ● Versatile attachments to accommodate various workpieces Convenient and User-Friendly Operability ● "Nidec Navi" supports program creation, centering, and other processes ● Simple collision prevention feature reduces accidents during debugging ◆ Product Detail Page https://www.nidec.com/jp/machine-tool/products/B700/M102/S100/NMTJ-mvrax/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Easy operability and maintainability for a simple and user-friendly experience. Efficiently supporting the production activities of customers dealing with can manufacturing and custom, small-lot processing. ● Original screen Nidec Navi Streamlining operator tasks ● Coolant guard on both sides of the table (optional) Facilitates workpiece placement while preventing chip scattering Producing diverse large parts with high efficiency Minimizing non-cutting time Rapid feed speeds: X-axis 30m/min, Y-axis 32m/min, Z-axis 20m/min, W-axis 5m/min Compatible with ATC (Automatic Tool Change), AAC (Automatic Attachment Change), and AAI (Automatic Attachment Indexing). Convenient attachments come standard Compact packaging for smooth delivery The compact packaging during delivery makes the process easy! Aging equipment located deep within the factory can be smoothly updated with the MVR-Cx. ◆ Product details page https://www.nidec.com/jp/machine-tool/products/B700/M102/S100/NMTJ-mvrcx/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The diverse layouts, including a four-head type opposing machine with four independent columns, significantly improve the productivity of large component machining. 【Table Moving Type】 MAF150S-T X-axis travel (mm) 7,500 (table movement) Y-axis travel (mm) 1,500-2,500 Z-axis travel (mm) 700 (boring) Boring spindle diameter (mm) 150 (taper 50) 【Column Moving Type】 MAF150S-C X-axis travel (mm) 6,000 (column traveling) Y-axis travel (mm) 1,500-2,500 Z-axis travel (mm) 700 (boring) Boring spindle diameter (mm) 150 (taper 50) ◆Product detail page https://www.nidec.com/jp/machine-tool/products/B700/M102/S102/NMTJ-maf150s-t_c/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Achieving a sufficient main spindle extension length that can firmly accommodate large structures. - MAF150C - Axis movement (mm) Column front and back X-axis 5,000 (opt. extended by 2,000 each) Ram saddle Y-axis 3,000 (opt. 4,000, 5,000) Ram left and right Z-axis 1,250 Boring spindle left and right W-axis 1,000 Diameter of the boring spindle (mm) φ150 Taper of the boring spindle No.50 - MAF180C - Axis movement (mm) Column front and back X-axis 5,000 (opt. extended by 2,000 each) Ram saddle Y-axis 3,000 (opt. 4,000, 5,000) Ram left and right Z-axis 1,250 Boring spindle left and right W-axis 1,000 Diameter of the boring spindle (mm) φ180 Taper of the boring spindle No.50 ◆Product details page https://www.nidec.com/jp/machine-tool/products/B700/M102/S102/NMTJ-maf-r_c_series/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Achieving a sufficient main spindle extension length that can firmly accommodate large structures - MAF130R - Axis movement (mm) Column front and back X-axis 5,000 to 21,000 Ram saddle Y-axis 2,500 (opt. 3,000, 3,500) Ram left and right Z-axis 700 Boring spindle left and right W-axis 700 Diameter of the boring spindle (mm) φ130 Taper of the boring spindle No.50 - MAF150R - Axis movement (mm) Column front and back X-axis 5,000 to 21,000 Ram saddle Y-axis 2,500 (opt. 3,000, 3,500) Ram left and right Z-axis 700 Boring spindle left and right W-axis 700 Diameter of the boring spindle (mm) φ150 Taper of the boring spindle No.50 ◆ Product detail page https://www.nidec.com/jp/machine-tool/products/B700/M102/S102/NMTJ-maf-r_c_series/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Powerful machining supported by a high-rigidity structure - MHT Series (1) Column Adopts a center-head type box column that achieves high rigidity and thermal stability. With a thermal target structure centered around the spindle, deformation due to cutting forces during machining is minimized, achieving stabilization of machining accuracy. (2) Table Table thickness increased by 30% compared to conventional machines. Boasting high rigidity, it ensures safety during heavy workpiece loading and heavy cutting, firmly securing high productivity. (3) Bed Adopts a T-shaped structure that strongly connects the table bed and column bed, achieving long-term stability of accuracy. Machining larger sizes with higher precision - MAF-E2 Series ● Class-leading spindle performance Supports various workpiece machining, including high-speed machining with small-diameter drills, low-speed high-power machining with large-diameter milling tools, and high-torque machining with large-diameter boring. ● The boring spindle's extension is class-leading at 800mm. ● Speedy movements reduce non-cutting time. ◆ Product detail page https://www.nidec.com/jp/machine-tool/products/B700/M102/S102/NMTJ-mht_maf-e2_series/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Significant Improvement in Productivity - Substantial reduction in non-cutting time with class-leading feed rates Rapid feed rates: X-axis 48m/min, Y-axis and Z-axis 32m/min - High-speed, powerful machining achieved with No. 50 spindle Maximum spindle speed: 7,000 min-1, spindle motor output: 26kW - Required installation area is at the minimum level compared to similar machines from other companies Installation space: 19.7 square meters (X-axis length 5.8m, Y-axis length 3.4m) ECO Operation - Significant reduction in oil usage Realized hydraulic unit-less design by adopting energy-saving, low-noise electric power units Lubrication requires only the replacement of a dedicated grease cartridge - Air consumption reduced to 40% of conventional machines (160L/min) ◆ Product details page https://www.nidec.com/jp/machine-tool/products/B700/M102/S103/NMTJ-mvbx2/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

High Rigidity - All major structural components use high-damping cast materials, achieving a structure with high dynamic rigidity. - The gantry structure is optimized for internal rib shapes and thickness through advanced structural analysis. - The Z-axis employs a sliding guide system, allowing for heavy cutting even when the spindle head is extended. High Productivity - Reduction of non-cutting time through high-speed rapid feed on each axis. - A wide machining area is achieved in a compact installation space. - Equipped with a high-efficiency spindle that can accommodate a variety of materials and tools. - A rich array of attachments (optional) supports five-sided machining (only for MV16Bx). User-Friendly - Standard equipped with the monitoring system "DIASCOPE" to support rapid troubleshooting and improve operational rates. - Standard equipped with a guidance function that allows easy operation from program creation to actual machining. - Standard equipped with a full-surround coolant guard and chip conveyor to prevent chip and coolant splatter, making handling easier. ◆ Product Details Page https://www.nidec.com/jp/machine-tool/products/B700/M102/S103/NMTJ-mvbx/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A prism rotator that adjusts the laser beam to any hole diameter and rotates it has been adopted in the head, enabling the processing of shapes with sharp edges. Additionally, it is also possible to process holes with any cross-sectional shape, such as straight, tapered, reverse tapered, and drum-shaped. It accommodates a wide variety of materials, including silicon wafers, SiC, machinable ceramics, platinum, stainless steel, and quartz glass.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

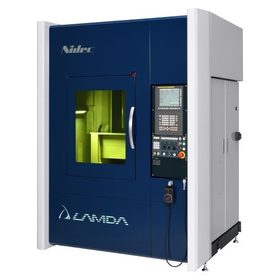

The features of the metal 3D printer LAMDA series include chamberless operation with local shielding and highly reliable additive manufacturing through monitoring feedback. ■ Local Shielding Laser light is directed onto the material to melt it, creating a localized oxygen-free environment at the tip. This technology enables additive manufacturing of anaerobic materials (such as titanium) even without a chamber. ■ Monitoring Feedback The state during the additive manufacturing process is monitored and fed back into the layering conditions. This allows for clean stacking without distorting the shape.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration