【Technical Information】Grooving Process for CMP Polishing Pads

In selecting CMP pads, I will explain about one of the components, the groove processing.

Generally, the surface of CMP pads is often grooved by the manufacturer before shipment. By applying groove processing to the surface of CMP pads, the following effects can be expected:

1. Improved retention and flowability of polishing slurry

2. Enhanced uniformity within the wafer surface and increased polishing rate

3. Prevention of wafer adhesion to the polishing pad surface

4. Discharge of processing debris and reaction byproducts

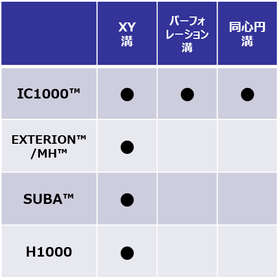

The main specifications for groove processing typically include XY linear grooves, perforation grooves (through holes), and concentric grooves, and in some products, combinations of these may be possible. Various specifications for XY linear grooves, such as groove width and pitch, are available.

We will select the optimal groove specifications tailored to your conditions, such as polishing equipment and processes, so please feel free to consult with us.

Inquiry about this news

Contact Us Online