CNET Connect Service will start selling the cloud service of the voice inspection system [LISTEST] from September, achieving not only improved efficiency and accuracy in inspection operations but also preventing fraudulent inspections and ensuring traceability of inspection content.

CNet Connect Service Co., Ltd. will start selling the cloud service of the voice inspection system [LISTEST] from September 2021.

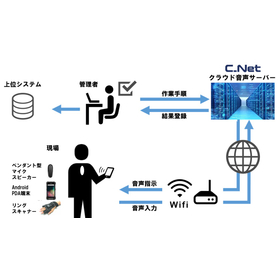

The voice inspection system [LISTEST] allows operators to perform tasks according to the work procedures instructed by the system, and if abnormal values are registered due to pre-set threshold settings for the measurement results, it prompts re-measurement, enabling the execution of procedures without relying on the operator's skills. Since the results are registered with the operator's speech simultaneously with the execution of the work, there is no need for input after inspection, which reduces the burden on the operator and prevents fraudulent inputs such as transcription errors, bulk input, and tampering.

In addition to the convenience of the voice system, by recording all work logs with timestamps, it ensures traceability for inspection, checking, and analysis tasks, which can be utilized for evidence management. This makes it effective as a subsystem for quality assurance and management tasks in manufacturing and service industries, where compliance is strictly required.

For product information on the voice inspection system [LISTEST], visit here:

https://www.cnet-technology.com/services/voice-system/listest

Inquiry about this news

Contact Us OnlineMore Details & Registration

Details & Registration

Related Links

This seminar, titled 'Ensuring Traceability in Inspection, Testing, and Analysis Operations through Voice Inspection', will introduce the background of development, solution features including a demo, and case studies.

Additionally, to help participants envision a concrete operational image, we will answer questions from attendees in real-time.

This seminar is recommended for those looking for realistic improvement measures for their inspection, testing, and analysis operations, regardless of industry or sector.

1) Where is Japan's manufacturing industry headed? What is needed for quality improvement?

2) Why do human errors occur?

3) What should be done to prevent errors?

4) What are the dangers of tampering and concealment?

5) Learning from errors: Traceability optimization solutions