A voice inspection system that ensures traceability for inspection, testing, and analysis operations / CCS boasts 14 years of voice system development and over 1,000 operational devices.

The voice inspection system combines voice guidance from the system (a speech synthesis engine that outputs instructions as voice) and the operator's spoken input (a speech recognition engine that recognizes words), allowing the operator to perform inspection, testing, and analysis tasks as if they were conversing with the system. By providing instructions verbally instead of referring to traditional procedure manuals, and recording results simultaneously with the operator's voice without the need for lists or pens, the system enables focused work that is eyes-free and hands-free. By issuing instructions through voice guidance, the system implements various functions to prevent human errors and improve work accuracy, including ensuring adherence to procedures, standardizing variations in skill levels, reducing the labor involved in result input and registration, and prompting the operator to redo work if they attempt to register incorrect results through system checks. Additionally, all work activities are recorded with timestamps, allowing for the verification of the entire work history, making tampering or concealment impossible. Statistical analysis of work data aids in the continuous improvement of quality management tasks, such as reviewing work procedures and setting up work assignments considering the suitability of operators, thereby contributing to evidence management.

Inquire About This Product

basic information

【Main Features】 1) Irreversibility: Confirmed data from procedural work cannot be changed. 2) Flexibility: Creation of voice flows is possible without programming. 3) Reliability: Work log data serves as useful evidence of adherence to procedures. 4) Rigor: Inspection procedures are centrally managed, and records of changes and additions are maintained. 5) Transparency: Scheduled and actual inquiries can be monitored by specific administrators. 6) Integrity: When operating across multiple locations, management at the same level is possible. 【Hardware】 As a cloud service, devices can be used in a Wi-Fi environment and can be implemented immediately if connected to the internet. By wearing a small, lightweight wearable device, the burden on workers is reduced, and work efficiency is improved. 1) PDA (Android) with voice recognition engine A compact and rugged PDA device is used as a work device, making it ideal for use in manufacturing environments. 2) Headset A headset for audio output and a microphone for input are essential. It is also possible to use a small, lightweight pendant-type device that combines a microphone and speaker. 3) Scanner (optional) A scanner for reading barcodes and QR codes is also available. Using a ring-type scanner that can be worn on the finger ensures workability.

Price information

Currently, the C-Net Connect Service is developing a package with user-friendly cloud services. We also accept customizations tailored to the operational needs of inspection, testing, and analysis tasks for each company. Please feel free to consult with us.

Delivery Time

Applications/Examples of results

[Suitable Applications for Use] - Inspection of materials, raw materials, and parts in the manufacturing industry, material mixing, product testing, etc. - Equipment and machinery inspection across all industries.

Detailed information

-

The positioning of the audio inspection LISTEST is equivalent to various subsystems involved in inspection, testing, and analysis operations, serving as a system that assists and records the progress of all tasks.

-

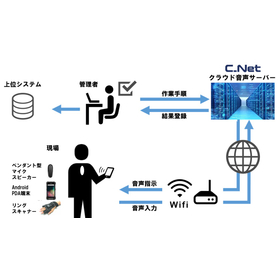

The system is provided as a cloud service, sending voice guidance of the configured work procedures from the administrator's PC to the worker's terminal equipped with a voice recognition engine via the cloud voice server. The worker performs tasks according to the instructions of the voice guidance output through headphones or a pendant speaker from the terminal and inputs the work results by speaking into the microphone connected to the terminal. The entered results are converted into data at the terminal and can be viewed by the administrator and multiple locations via the cloud voice server. The confirmed results cannot be changed. They can be integrated into higher-level systems such as quality management systems, enabling their use for evidence management through the assurance of traceability.

-

The voice conversation flow for instructing work content can be set and changed by the administrator without programming. It can always be optimized according to the practical operations of inspection, testing, and analysis tasks, and can be flexibly improved as needed based on statistical data regarding procedures that require rework or time-consuming tasks.

-

By having the administrator set predetermined minimum and maximum values for the results of each task in advance, it is possible to configure the system to prompt a redo of the task when incorrect values are entered due to the worker's misreading or misunderstanding. Since the worker can perform re-measurements and other tasks on the spot, this eliminates the inefficiency of having to redo the work later and also helps prevent fraud, such as tampering with the results.

catalog(1)

Download All CatalogsNews about this product(2)

Company information

Our company is engaged in the development and sales of voice recognition systems, as well as the sale and repair of various terminal devices. We aim to be a group that provides systems that fundamentally assist our customers, not just from a technical perspective. We also achieve this by combining various mechanisms, skills, and human networks to connect and integrate them.