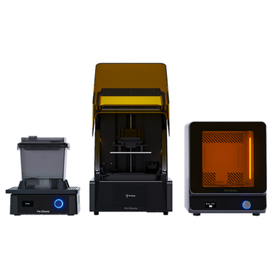

High-precision light curing technology and the industry's fastest turnaround! Meticulously responding to customer needs such as transparent resins and painting!

Achieving a shortened development process with the world's fastest light-curing resin prototype! Stereolithography uses laser beams and light-curable resin to create layered structures based on 3D CAD data, allowing for the rapid production of physical models that are identical to those designed in 3D CAD. Compared to complex shape machining, it enables an overwhelming reduction in time, and it can create intricate shapes, including undercuts and hollow structures, that are impossible with machining. It can also accommodate sudden design changes at an exceptionally low cost. We provide various benefits such as shorter development periods and cost reductions by creating faster and more detailed three-dimensional models.

Inquire About This Product

basic information

Light-curing resin: Epoxy-based UV-curable resin Characteristics of the resin: Heat resistance/toughness, moisture resistance/heat resistance, high rigidity/suitable for casting Appearance: Light yellow, highly transparent, clear Manufacturable size Our light-curing equipment can produce sizes of approximately 600×600mm in the X and Y (length and width) dimensions, and 200 to 500mm in the Z (height) dimension (height may vary depending on the machine, so consultation is required). Products that fit within this volume can be produced as a single piece. Additionally, larger products can be produced by dividing them into parts and then bonding them together.

Price information

-

Delivery Time

P1

Applications/Examples of results

- Confirmation of design and shape - Evaluation of design - 3D data check - Mockups for exhibitions, shows, and presentations - Visualization evaluation - Verification of molds - Master model for casting

Detailed information

-

Transparent Light Stereolithography Unmatched transparency and moisture resistance in the industry Light stereolithography using transparent resin is ideal for fitting verification of enclosures and flow path analysis. It allows for overwhelming time savings, enabling shape verification of transparent resin to be possible as early as the next day. Transparent light stereolithography products can be utilized in a wide range of fields, including various flow path analyses, prototypes for home appliances and engine development, and organ and skeletal models in the medical field.

-

Light Shaping Express The world's fastest service. If it takes more than 24 hours, we will not charge you for your order. After receiving the 3D data, you can confirm the prototype within 24 hours. We flexibly support product development in a short period and sudden design changes. Supporting development within a limited timeframe. 24-hour guaranteed express service In the field of product development, the rapid changes in consumer needs demand a significant reduction in development time. At Cross Effect, we are committed to thoroughly supporting development within limited timeframes, aiming for the world's fastest manufacturing.

-

Small Economy Service In exchange for specifying the delivery date, we guarantee overwhelmingly low-cost light sculpting. If you place multiple orders, we can offer even lower prices. Supporting development within a limited budget To win in the development competition, the production of prototypes within a limited budget is required. By allowing us to specify the size and delivery date, we have created a price that you can be sure to be satisfied with. This is a service you can confidently request even with sudden design changes.

-

Quality High precision in rapidly creating shapes that match the data. It can maintain 3D data with an error of ±0.05 to 0.1mm (for a 150mm square). The layer thickness (height per layer) can be varied from 0.05 to 0.2mm. Additionally, we offer transparent resin that enables the "visualization" of internal structures. Furthermore, it can be used as a master for vacuum casting, and we can also provide prototypes that are closer to mass-produced products through surface treatment and painting embellishments.

-

The resin for light shaping is an epoxy-based UV-curable resin. Compared to conventional resins for light shaping, it has excellent toughness, such as self-tapping and snap-fit properties, and possesses strength and toughness comparable to ABS materials, making it suitable for fitting and screw fastening without any issues, thus usable for initial prototypes. Additionally, the transparent resin is suitable for flow analysis and fit verification, and it also has excellent moisture resistance, so there is no concern about deformation due to humidity.

-

Speed Compared to conventional speeds, shape confirmation is possible in about one-third of the time. With astonishing speed, even resin assembly products can be confirmed in just a few days. For fit verification, it is possible to check parts for different applications (machined parts, sheet metal, circuit boards, etc.) in a short time. We also offer a high-speed service that allows for prototype confirmation within as little as 24 hours, providing flexible support for product development with short lead times and sudden design changes.

catalog(1)

Download All CatalogsCompany information

We believe that the greatest value we can provide to our customers is "time-saving," and we are constantly working on reforming our awareness of time. In recent years, our "time-saving technologies" have gained recognition not only in the industrial sector for development support but also in the medical field. All employees think from the client's perspective, contributing to customers and society with our exceptional advanced manufacturing technologies in this rapidly changing era. We believe this is the mission entrusted to us. As a frontrunner in 3D engineering, we will always lead our customers and grow into a "shining company" together with our valued clients through cutting-edge technologies that exceed expectations. Please look forward to this ever-evolving group of engineers.

![[Design Support] Prototype Production_Service Price List](https://image.mono.ipros.com/public/product/image/6d9/2000551437/IPROS73504215603729130567.jpeg?w=280&h=280)