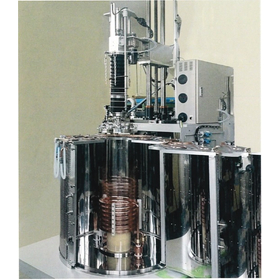

Furnace equipped with a high-speed cooling system capable of handling temperatures up to 1650℃.

This dental furnace is optimal for firing trans-zirconia due to its maximum temperature of 1650℃. The electrically operated furnace floor allows for easy placement of firing trays. The heating element made of molybdenum disilicide provides optimal protection against chemical contamination for crowns and bridges. Dental copings can be placed on ceramic firing trays. Since up to three firing trays can be stacked, high productivity is achieved.

Inquire About This Product

basic information

The "LHT 02/17 LB Speed" furnace for open dental CADCAM is equipped with a high-speed cooling system. The table automatically opens in stages for rapid cooling. Depending on the type of zirconia, it is also possible to significantly reduce the firing time.

Price information

Prices fluctuate due to exchange rates and options. Please feel free to contact us.

Delivery Time

※Delivery dates may vary depending on the options. Please feel free to contact us.

Applications/Examples of results

- Maximum temperature 1650℃ - High-quality heating element made of disilicide molybdenum to prevent chemical interaction between the coping and the heating element - Furnace chamber lined with high-quality fiber material - Excellent temperature distribution due to all-around heating of the furnace chamber - Furnace chamber with a volume of 2 liters and a spacious tabletop - Push-button operation with electric axial drive; automatic opening for cooling is possible in high-speed models - Body made of stainless steel rolled plate - Exhaust vent in the furnace ceiling - High-speed models equipped with drying function

Company information

Sales Information: CNC 6-axis and 8-axis automatic lathes, CNC tool grinding machines (Schütte) CNC rotary transfer machines, CNC 5-axis multi-tasking machines (Nutti) 5-axis milling machines, jig grinding machines (Ledaers) Three-dimensional measuring machines (Beato) Thread cutting die heads, thread rolling heads (Wagner) Grinding head traveling surface grinding machines, tool grinding machines, circular knife grinding machines (Geckel) Automatic bar feeding devices for multi-axis automatic lathes (Cookie) Automatic die casting machines for brass, brass melting furnaces, core forming machines (I.M.R) Hot forging presses for brass with "sub-press for hollow forging," screw presses for iron/non-ferrous forging (Mecol Press) Progressive cold formers, warm formers, thread rolling centers (Sakuma) Quick change collets (Heinbuch) Center hole grinding, lapping machines (Klein) Others

![[Technical Column] Explanation of Types and Components of Heating Furnaces and Heating Methods](https://image.mono.ipros.com/public/product/image/b51/2000729545/IPROS71443779370121838519.png?w=280&h=280)

![Butterfly Valve BV Series [2D/3D CAD]](https://image.mono.ipros.com/public/product/image/7a0/2000815776/IPROS65074472961613162442.jpeg?w=280&h=280)

![Challenging Decarbonization Technologies! Introduction to the Thermal Technology Research Institute [Latest Information for 2025!]](https://image.mono.ipros.com/public/product/image/3d5/2000834196/IPROS99631596500298700026.jpeg?w=280&h=280)

![Venturi Mixer VM Series [2D/3D CAD]](https://image.mono.ipros.com/public/product/image/d2e/2000852305/IPROS58786938329892851049.png?w=280&h=280)