A new communication module for direct control of an ultrasonic oscillator from a PLC.

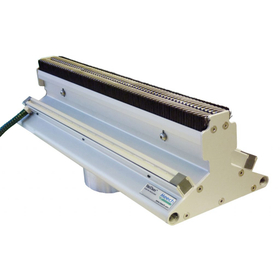

iQLinQ(TM)

All functions of the ultrasonic oscillator can be directly controlled/monitored with a single cable!

The communication module "iQLinQ," developed for the Duquesne iQ series probe oscillator, allows for direct control and monitoring of the ultrasonic oscillator from a PLC when used in combination with an automatic machine. The cumbersome wiring task of connecting each conventional I/O signal to terminals is completed simply by connecting one cable to a connector. This eliminates the hassle of wiring work and wiring errors, significantly reducing the engineering costs involved. Additionally, all welding control settings, data monitoring, limit settings, and confirmation of judgment results can be performed from the PLC, allowing the ultrasonic oscillator to be fully integrated and used as part of the automatic machine. In traditional methods, an analog unit was required for amplitude control and oscillation output signals, but using "iQLinQ" eliminates the need for these analog units. This new era communication unit completely disrupts the conventional control methods for ultrasonic oscillators in automatic machines, further enhancing the combination of the automatic machine and ultrasonic oscillator, and greatly contributing to the overall functionality of the equipment.

Inquire About This Product

basic information

Dukein's iQLinQ is a proprietary communication protocol for connecting, controlling, and monitoring automatic devices and ultrasonic oscillators. It is compatible with the iQ series probe oscillators and supports industrial communication protocols such as Ethernet/IP, CC-Link, ProfiBus, and EtherCAT. iQLinQ is a solution that simplifies the communication protocol between Dukein's iQ series probe oscillators and the PLC of automatic devices. By adopting iQLinQ, various benefits arise, including reduced engineering costs (for programming and wiring work), elimination of the risk of incorrect wiring, and enhanced functionality of devices due to the ability to control and monitor all functions. Users can set welding conditions and obtain real-time data and welding result data entirely from the PLC by using iQLinQ. The combination of the reliable digital control of the iQ oscillator, which provides precise and stable welding, and iQLinQ also contributes to further cost and downtime reduction.

Price range

P3

Delivery Time

P4

Applications/Examples of results

It is used for controlling and monitoring a probe system that controls an ultrasonic oscillator with an automatic machine.

Detailed information

-

iQLinQ Usage Example All parameters can be set and monitored from the device's touch panel.

catalog(1)

Download All CatalogsCompany information

Dukane Japan is the Japanese subsidiary of Dukane IAS LLC, headquartered in St. Charles, Illinois, USA. It supports various plastic welding processes with its unique advanced technologies, including ultrasonic servo welders utilizing servo control technology, ultrasonic probe systems that can be controlled and monitored from external PLCs via Ethernet IP connection or CC-Link connection, vibration welders capable of high-precision welding with high mechanical rigidity, and the Servo Weld Plus (Dual Servo) spin welder that performs rotation and pressure control via servo. Additionally, with the motto "One World, One Dukane," it offers comprehensive support in countries and regions outside Japan through a worldwide network that spans major industrial nations. This allows for the relocation of equipment purchased in Japan to overseas locations for local service, as well as the maintenance of equipment relocated from abroad in Japan.