IoT Equipment Operation Monitoring and Performance Management System 'Facteye'

Equipment operation monitoring and performance management system "Facteye"

"Visualization" system compatible with equipment operation performance collection and real-time monitoring *Demo available

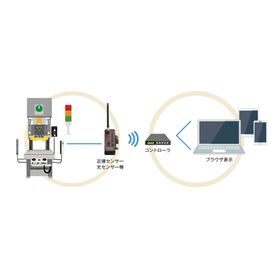

Facteye is a system that allows for easy collection of operational history from various equipment. Based on operational performance data, it enables a wide range of applications such as automatic report generation, operational analysis, and monitoring, making it a "visualization" system. 【Collection of Equipment Operational Performance】 It collects detailed operational performance data such as the operational status of each piece of equipment, various signals, alarm contents, and programs, allowing for the identification of various challenges on-site. 【Real-Time Monitoring of Operational Status】 You can monitor the operational status anytime using a smartphone or PC. Additionally, when an alarm occurs, an email notification is sent, enabling immediate response to any issues that arise. 【Direct Data Acquisition from Various CNCs】 By directly acquiring data from CNC control devices, it is possible to obtain detailed data on operational conditions, types of alarms, programs, and machine statuses. Analyzing this wide range of data allows for clearer identification of issues. 【Centralized Management Regardless of Equipment Manufacturer or Age】 It supports connections with CNCs from six domestic machine tool manufacturers. It also accommodates connections with devices like Patlite and relays, allowing for visualization even with older models that cannot directly acquire data from CNC control devices. This enables centralized management of all equipment within the factory.

Inquire About This Product

basic information

【Examples of Collectible Data】 - Operating status, signal status, operating mode, modal data, processing results, NC data - Status of servo motors, alarms/messages, status of spindle motors, coordinate-related data, operation history, etc. 【CNC Manufacturers Compatible for Connection】 Fanuc, Toshiba Machine, Brother Industries, Okuma, Mitsubishi Electric, Yamazaki Mazak *Depending on the machine and the series or model of the CNC, there may be cases where data cannot be obtained or where the obtainable data may differ.

Price range

Delivery Time

Applications/Examples of results

This is a suitable operation monitoring and performance management system for those who are dissatisfied with equipment operating conditions, want to identify the causes of productivity decline, and wish to shorten working hours for work style reform.

catalog(1)

Download All CatalogsCompany information

【Proposing the latest and standard equipment for manufacturing through a system】 We are the only company in Japan that can provide a comprehensive proposal for all the equipment necessary for manufacturing, including machine tools, CAD/CAM, 3D printers, 3D scanners, and other 3D digital production tools and instruments. 【Peace of mind with technical support after installation】 With our strength in technical support, we can resolve any concerns of users after installation, such as operation assistance, troubleshooting, and maintenance, all through a single point of contact. 【Extensive display of actual machines】 We have various actual machines set up, allowing you to clarify your operational image through demonstrations and tours before making a decision to implement. 【Manufacturer capabilities】 Additionally, if there are no products with the features desired by users, or if there are products with good features but weak sales power, we will leverage our manufacturer capabilities to release them as uniquely planned in-house products.