Ultrasonic welding machine - An ultrasonic welding machine that achieves stable welding in packaging equipment.

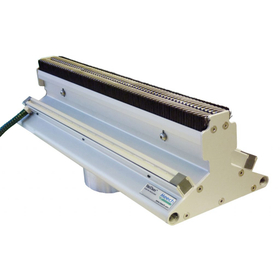

iQ Series Ultrasonic Probe Unit

The digital control ultrasonic oscillator that achieves stable ultrasonic sealing in packaging machinery supports high-speed operation and enhances the reliability of the sealing device.

To achieve a stable seal, a stable ultrasonic oscillator is essential. Duquesne's ultrasonic oscillator for automatic machines uses the same digital oscillation circuit as high-end models and is a low-cost oscillator that incorporates only the functions necessary for use in automatic devices. It is equipped with all the necessary features for stable welding, including auto-tuning of frequency, line regulation, load regulation, external amplitude control functions, and various I/O signals. Additionally, by utilizing Duquesne's proprietary iQ-LinQ (Ethernet/IP or RS232) connection, all control and monitoring can be done with a single cable to the PLC, reducing wiring labor and expanding the flexibility of ultrasonic welding control.

Inquire About This Product

basic information

Model: iQ-AiM Frequency: 15kHz/20kHz/30kHz/35kHz/40kHz Maximum Output: 3600W/5000W (15kHz) 1200W/2600W/3600W/5000W (20kHz) 900W/1200W/1800W (30kHz) 900W/1200W (35kHz) 900W/1200W (40kHz) Oscillation Control: Time/Energy/External Signal/Distance (requires external encoder) Frequency Adjustment: DigiTrack Auto Tuning Amplitude Control: 20-100% (set by oscillator or external control) Others: Line regulation, load regulation functions Overload protection circuit, output trigger (patented technology) iQ-LinQ communication protocol compatible (Ethernet/IP, CC-Link, etc.) Model: iQ-Auto Plus Frequency: 20kHz/30kHz/35kHz/40kHz Maximum Output: 600W Oscillation Control: Signal from external PLC Frequency Adjustment: DigiTrack Auto Tuning Others: iQLinQ compatible

Price range

Delivery Time

P4

Applications/Examples of results

Used for packaging seals, carton cup seals, carton flange presses, and food processing, among other applications.

Detailed information

-

The new iQ-AiM series of ultrasonic oscillators features a newly designed oscillation circuit that enables more efficient ultrasonic oscillation compared to conventional models (iQ-LS), achieving even more stable sealing and welding. In addition to on/off control via external signals, it also supports time control and energy control functions, and includes a patented output trigger function that stabilizes the state at the start of oscillation. Communication with external PLCs is compatible with Ethernet/IP and CC-Link, allowing all control to be managed with a single cable.

Line up(2)

| Model number | overview |

|---|---|

| iQ-Auto-Plus Series | This is a compact type oscillator that performs all control and monitoring from the PLC. It is ideal for applications with a small sealing area. |

| iQ-AiM Series | The new ultrasonic oscillator iQ-AiM series is equipped with a newly designed oscillation circuit that enables more efficient ultrasonic oscillation compared to the conventional model (iQ-LS), achieving even more stable sealing and welding. In addition to on/off control via external signals, it also supports time control and energy control functions, and features a patented output trigger function that stabilizes the state of oscillation start. Communication with external PLCs is compatible with Ethernet/IP and CC-Link, allowing all control to be done with a single cable. |

catalog(3)

Download All CatalogsCompany information

Dukane Japan is the Japanese subsidiary of Dukane IAS LLC, headquartered in St. Charles, Illinois, USA. It supports various plastic welding processes with its unique advanced technologies, including ultrasonic servo welders utilizing servo control technology, ultrasonic probe systems that can be controlled and monitored from external PLCs via Ethernet IP connection or CC-Link connection, vibration welders capable of high-precision welding with high mechanical rigidity, and the Servo Weld Plus (Dual Servo) spin welder that performs rotation and pressure control via servo. Additionally, with the motto "One World, One Dukane," it offers comprehensive support in countries and regions outside Japan through a worldwide network that spans major industrial nations. This allows for the relocation of equipment purchased in Japan to overseas locations for local service, as well as the maintenance of equipment relocated from abroad in Japan.

![Suppressing contaminant residue! Introduction of thermal fusion [PFA beadless welding technology].](https://image.mono.ipros.com/public/product/image/29a/2000338690/IPROS1623617675991867896.jpg?w=280&h=280)