Long lifespan, maintenance-free Chubo Tal (radiant heater) performance collection

We will introduce examples used in automobile parts manufacturers and bearing manufacturers.

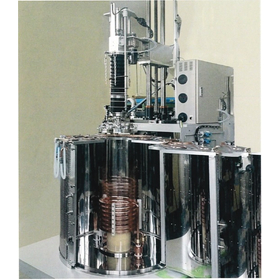

In the case study of Tubothal (radiant heater), examples are presented from "automobile manufacturers," "spring manufacturers," "heat treatment manufacturers," and "bearing manufacturers" that use the long-lasting, maintenance-free Tubothal. Tubothal combines a radiant heater using Kanthal APM as the heating element with APM-made radiant tubes. ■ Featured Cases ■ ○ Major automobile manufacturers ○ Automobile parts manufacturers ○ Spring manufacturers ○ Heat treatment manufacturers ○ Bearing manufacturers, etc. For more details, please contact us or download the catalog.

Inquire About This Product

basic information

□Publication Contents□ ○Issues with Radiant Heaters ○What is Tubothal? ○What benefits does it offer? ○CASE 1 – Major Automobile Manufacturer ○CASE 2 – Automotive Parts Manufacturer →Solving troubles caused by scale ○CASE 3 – Automotive Parts Manufacturer →Reducing tube bending and extending lifespan ○CASE 4 – Spring Manufacturer ○CASE 5 – Automotive Parts Manufacturer →Annual cost reduction of 1 million yen ○CASE 6 – Heat Treatment Manufacturer →Contributing to an annual sales increase of 2.6 million yen ○CASE 7 – Heat Treatment Manufacturer →Trial results good → Complete replacement ○CASE 8 – Heat Treatment Manufacturer →Trial results good → Regular purchases ○CASE 9 – Automobile Manufacturer ○CASE 10 – Bearing Manufacturer →Trial results good → Complete replacement ○CASE 11 – Steel Manufacturer ○CASE 12 – Automobile Manufacturer ○CASE 13 – Steel Pipe Manufacturer ●For more details, please contact us or download the catalog.

Price information

Please contact us.

Delivery Time

※Please contact us.

Applications/Examples of results

For more details, please contact us or download the catalog.

catalog(2)

Download All CatalogsCompany information

We manufacture heating materials at our headquarters in Sweden and provide heating systems tailored to the needs of our Japanese customers by designing and manufacturing domestically. We have a domestic manufacturing base in Sakura City, Chiba Prefecture, where we process the final products and deliver them to our Japanese customers. By focusing on domestic design and manufacturing, we have established a system that ensures customer satisfaction with our response times and after-sales service.

![[Case Studies Available] Centralized Management of Facility and Equipment Information with Facility Management System!](https://image.mono.ipros.com/public/product/image/41d/2001501178/IPROS29610556803641576895.png?w=280&h=280)

![[Catalog Presentation] NSP Wooden Play Equipment "Creation"](https://image.mono.ipros.com/public/product/image/2ec/2000523071/IPROS33170091326435291218.png?w=280&h=280)

![[Book] Firing and Sintering Techniques for Ceramics and Metals (No. 2237)](https://image.mono.ipros.com/public/product/image/451/2001129378/IPROS62003523544646185428.gif?w=280&h=280)