For use in healthcare, food, mining, and more! An analysis tool that accurately predicts the behavior of various powders.

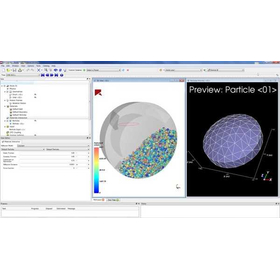

IDAJ's "Rocky DEM" is a powerful particle simulator that accurately predicts the behavior of powders with different shapes and sizes using the discrete element method. By modeling non-spherical particles as polyhedra, it achieves high-precision powder analysis. Real particles can be scanned in 3D and used for powder analysis. High-speed powder analysis is realized through Shared Memory parallel computing using GPUs. 【Features】 ■ High-precision powder analysis with real-shaped particles ■ High-speed computation with GPUs ■ User-friendly interface ■ Rich result processing capabilities ■ Coupled analysis with Ansys tools ★ Please watch the case studies in the video on the IDAJ official YouTube Channel "Rocky DEM" https://www.youtube.com/watch?v=lytQ472Xuzw&list=PLcvnp-10UZJHpVWjfXvMAlpvVkcZ4ZJg3 * For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

【Features】 ■ Shared memory parallel computation using CPU ■ Shared memory parallel computation using single and multi-GPU ■ Particle rotation resistance model ■ Particle contact model ■ Wall wear model due to particles ■ Particle breakage model ■ Heat exchange model ■ Rocky standard particle shape model *For more details, please refer to the PDF materials or feel free to contact us. ★ Please watch the case studies on video. IDAJ Official YouTube Channel "Rocky DEM" https://www.youtube.com/watch?v=lytQ472Xuzw&list=PLcvnp-10UZJHpVWjfXvMAlpvVkcZ4ZJg3

Price range

Delivery Time

Applications/Examples of results

Bidirectional coupled analysis of tablet drying process using Ansys Fluent and Rocky DEM Tablet coating for food and pharmaceuticals Unidirectional coupled analysis of solid particle separation by airflow using Ansys Fluent and Rocky DEM Bidirectional coupled analysis of fluidized bed using Ansys Fluent and Rocky DEM Discharge of rocks from the bed of a dump truck Mixing of wet cement using a ring pan mixer Excavation and movement by an excavator Slurry mixing inside a grinder Particle analysis in a high shear granulator (150L, full-scale) with 10 million particles Transportation of ore using a bucket elevator Particle mixing inside a plow mixer Seasoning process for snack chips (custom particles) Off-road driving simulation Air and dust flow within a conveyor chute Liner wear inside a crusher Particle breakage and crushing Particle transportation using a conveyor belt Prediction of particle behavior to resolve blockages in a chute Heat transfer of particles inside a hot air oven Separation and classification of three sizes of particles using a vibrating screen Transportation of wet, sticky ore particles Mixing inside a cement mixer using settings for high stickiness and dynamic friction particles, among others *For more details, please feel free to contact us.*

catalog(1)

Download All CatalogsNews about this product(3)

Company information

While focusing on MBD and CAE technologies and their surrounding technical areas, we specialize in building virtual products and collaborative design processes through cutting-edge digital engineering. We have formed partnerships with leading software vendors of the era to provide top-level digital engineering technologies in Japan, including solutions for thermal fluid analysis, structural analysis, electromagnetic field analysis, acoustic analysis, system simulation, optimization technologies, embedded software development environments, and simulation process data management (SPDM) solutions. We offer a comprehensive engineering environment necessary to solve the diverse and complex challenges faced by our customers. Official Blog: https://www.idaj.co.jp/blog/ IDAJ YouTube Channel: https://www.youtube.com/channel/UCGCd8pB5Lwq_noIoxpgJrrw/featured X: https://twitter.com/IDAJ_CAE Facebook: https://www.facebook.com/IDAJ.CAE

![[September 5 (Wednesday) Kobe City, Hyogo Prefecture] Seminar introducing the general-purpose powder analysis tool "Rocky DEM" and the latest DEM technology.](https://image.mono.ipros.com/public/news/image/1/baf/46435/IPROS2556053650795949938.jpg?w=280&h=280)

![[Case Study] Cost Reduction and Performance Improvement of Hydraulic Control Equipment](https://image.mono.ipros.com/public/product/image/69b/2000426794/IPROS13774034196516722779.jpg?w=280&h=280)

![[Free Download of Materials - Acoustic Analysis] Noise Control](https://image.mono.ipros.com/public/product/image/49d/2000787714/IPROS63881842644404875960.jpeg?w=280&h=280)

![[Example] Vibration of liquid tanks and sloshing of the liquid surface during an earthquake.](https://image.mono.ipros.com/public/product/image/3d7/2000246820/IPROS13742124745136167881.jpg?w=280&h=280)