Powerful removal and prevention of strong slag (dross) adhering to furnace walls and ladles! You will no longer have to worry about slag!

Are you troubled by the troublesome "slag" that increases every time you melt metal, blocking your furnace walls and ladles, wearing out your refractory materials, and causing poor slag removal? The "Slag Conditioner TL" is designed to tackle such stubborn slag. By simply adding it along with your melting materials, it helps float the slag to the surface, allowing you to easily collect and remove it with your usual slag removal materials. This product provides the effect of "slag removal." After cleaning, by continuing to add a small amount to the melting materials, it reacts with the "slag precursors" inside the molten metal, preventing the slag from strongly adhering to the furnace walls by causing it to float to the surface instead. This product offers two effects: "slag removal" and "slag adhesion prevention." If you are facing issues with slag, please do not hesitate to consult us.

Inquire About This Product

basic information

● Reducing the "cost" known as "slag" By using the "Slag Conditioner TL," many users have experienced the following effects and benefits: - Reduction in slag removal work - Decrease in electricity consumption per ton of metal melted - Improvement in melting speed - Reduction in slag-related defects - Extension of refractory lifespan, etc. As a means to reduce the "cost" of "slag," which has been taken for granted until now, we encourage you to utilize the "Slag Conditioner TL." ● Free of fluorine compounds, environmentally friendly for both the environment and the furnace Unlike traditional removal agents represented by "fluorspar" (calcium fluoride), this product contains no fluorides at all. Therefore, it is very gentle on both the environment and the furnace itself. 【Product Overview】 ■ Packaging: 1 box (20 kg) [100 g small bags × 200 bags] ■ Recommended usage: Slag removal... 500 g (5 bags) per ton of melted metal Slag adhesion prevention... 100-200 g (1-2 bags) per ton of melted metal ■ Compatible equipment: High-frequency furnaces, medium-frequency furnaces, low-frequency furnaces, ladles, etc. ■ Melting temperature: Approximately 1,100℃

Price range

Delivery Time

※Regular stock products

Applications/Examples of results

* "Melting furnaces, ladles, and holding furnaces for cast iron (FC, FCD, etc.), cast steel (including stainless cast steel), and copper alloy casting." * "Numerous achievements both domestically and internationally."

Detailed information

-

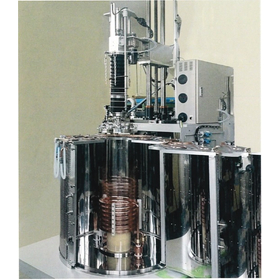

Slag Conditioner TL - Melting Furnace Before Use

-

Slag Conditioner TL After Use Melting Furnace

catalog(1)

Download All CatalogsCompany information

Thank you for your interest in our company page. We are a chemical manufacturer specializing in the metal processing field, focusing on release agents and coatings, and primarily engaged in the development and sales of "casting-related products," "special chemical products," "petroleum products," and "environmental improvement products." In particular, we aim to develop niche products that our customers can say, "These are not commonly available, but they would be helpful!" We listen to our customers' requests daily. If you are currently facing any challenges at your company, please feel free to consult with us. Additionally, we import casting auxiliary materials and shot blast-related products from our overseas branches, and we collaborate with used machinery dealers and equipment suppliers nationwide to support our customers from the sale of the equipment they are looking for to after-sales follow-up. We have agents in countries such as "South Korea," "China," "Thailand," "Indonesia," "Vietnam," and "Taiwan," so please consult with us if you are considering expanding overseas. To realize our customers' needs, we will conduct research and development of products with a new perspective, free from conventional wisdom. Please do not hesitate to contact us.

![Reasonable experimental table - Lab table for experiments [Video available]](https://image.mono.ipros.com/public/product/image/a12/2000642817/IPROS83593351681460979832.jpeg?w=280&h=280)

![[Book] Firing and Sintering Techniques for Ceramics and Metals (No. 2237)](https://image.mono.ipros.com/public/product/image/451/2001129378/IPROS62003523544646185428.gif?w=280&h=280)