A new vibration welding solution that reduces particles generated during welding by increasing the vibration frequency and decreasing the amplitude!

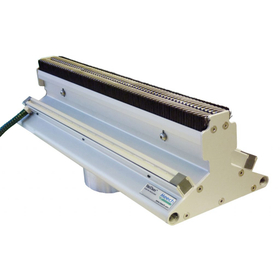

At Duquesne, we developed a high-frequency vibration welding machine that increases the number of vibrations with a smaller amplitude to reduce the burrs generated during vibration welding. While the frequency of typical vibration welding machines ranges from 200-240Hz, our high-frequency model vibrates at a frequency of 295-350Hz, allowing us to reduce the conventional amplitude from 0.5-1.8mm to 0.3-1.1mm. This change enables us to decrease both the quantity and size of particles generated. The table drive utilizes the latest servo control technology, similar to the standard VW6700, featuring synchronized dual servo motors for table drive control. This results in high-speed table movement, high positional accuracy, and excellent reproducibility.

Inquire About This Product

basic information

- Electromagnetic vibration head (frequency: 295–350Hz) - High-rigidity 4-axis linear slide lift table - Integrated frame structure with class-leading rigidity - Tube-type steel lift table - Digital frequency variable drive with a maximum output of 33.5kW - Servo motor-driven table with a maximum load of 22 kN - Real-time graph display function for amplitude, load, and distance - Industrial computer control with a 15-inch color touch panel - Control of mechanisms for work clamps, ejectors, and suction devices is programmed via the touch panel - Supports 6 work sensors as standard (expandable up to 10) - Supports control of 6 solenoid valves for fixtures (capable of supporting 12 cylinder sensors) - Supports dual suction systems - Automatic fixture identification function - Multilingual display function (select two from Japanese, English, Spanish, German, French, Czech, Chinese) - Automatic tuning function for fixture frequency - Adjustable amplitude range from 0.3 to 1.1mm

Price range

P7

Delivery Time

Applications/Examples of results

Various automotive parts (glove box, center console, spoiler, cylinder head cover, intake manifold, resonator, canister, air filter, liquid tank, etc.) Various electrical products (balance ring, heat exchanger, warm water washing toilet seat, toner cartridge, bathroom control panel, etc.)

Line up(2)

| Model number | overview |

|---|---|

| VW6700HF | Upper fixture weight 40-67kg |

| VW6700LPTHF | Upper fixture weight 28-82kg |

catalog(1)

Download All CatalogsCompany information

Dukane Japan is the Japanese subsidiary of Dukane IAS LLC, headquartered in St. Charles, Illinois, USA. It supports various plastic welding processes with its unique advanced technologies, including ultrasonic servo welders utilizing servo control technology, ultrasonic probe systems that can be controlled and monitored from external PLCs via Ethernet IP connection or CC-Link connection, vibration welders capable of high-precision welding with high mechanical rigidity, and the Servo Weld Plus (Dual Servo) spin welder that performs rotation and pressure control via servo. Additionally, with the motto "One World, One Dukane," it offers comprehensive support in countries and regions outside Japan through a worldwide network that spans major industrial nations. This allows for the relocation of equipment purchased in Japan to overseas locations for local service, as well as the maintenance of equipment relocated from abroad in Japan.