It is possible to easily and stably produce sintered rods with the same sintering density that are straight!

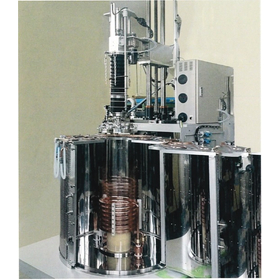

The single crystal growth using an optical floating zone melting device is a method that continues the melting and solidification of the sample while retaining the melt in the sample rod itself, making the production of the sample rod the primary important task. This product consists of a sample rotation and elevation device and a vertical annular furnace, allowing for the easy and stable production of straight sample rods with the same sintering density. Furthermore, by adding a slow feed function, it can also be used for Bridgman method crystal growth in addition to the aforementioned rotation and elevation functions. 【Features】 ■ Efficient production of straight sintering raw material rods with the same sintering density, particularly suitable for the FZ method ■ Adoption of a touch panel that excels in ease of setting and operability ■ Addition of a slow feed function to the drive system, allowing it to be used as a Bridgman furnace ■ Heating elements made of MoSi2, with a maximum temperature of 1800℃ ■ Capable of flowing a single type of atmosphere gas within the furnace *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

【Specifications (Excerpt)】 ■ Maximum Operating Temperature: 1800℃ ■ Normal Operating Temperature: 1700℃ ■ Heater ・MoSi2: 6 pieces ・Size: 200×200×6×3×25 (mm) ■ Sample Chamber Shape ・Vertical tubular furnace: φ60×900 (mm) ・Lower water-cooled jacket ■ Insulation Material: Alumina, special ceramic *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Crystal System Co., Ltd. has developed a unique single crystal manufacturing device that uses a quadrupole mirror to produce high-quality crystals through the melting of raw material rods with infrared irradiation and the floating zone melting method. We will continue to provide products that are always ahead of the times, tailored to meet the diverse needs of our customers.