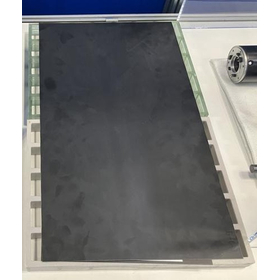

Coaxial barrel-type plasma device

In addition to the ashing applications for semiconductor wafers and small substrates with photoresist, it is effective when you want to utilize processing from all directions using isotropic plasma. For mass production, please refer to the YSP650W, which processes 50 sheets at a time.

Inquire About This Product

basic information

Model: YSP1000B Coaxial barrel type Electrode structure: cylindrical, quartz chamber High frequency output (Max): 1KW Oscillation frequency: 13.56MHz crystal oscillator Chamber dimensions (internal): Φ300×500mm Chamber material: quartz Reaction gas: 2 systems Vacuum pump: dry pump (approximately 500L/min) Gas inlet: 2 for reaction gas, 1 for purge, 1 for air

Price range

Delivery Time

Applications/Examples of results

- Ashing of photoresist on semiconductor wafers and small substrates - Isotropic etching - Wettability improvement, surface modification, etc. Quartz chamber size: φ300 × L500 mm. This is effective not only for ashing photoresist on semiconductor wafers and small substrates but also when utilizing isotropic plasma for processing from all directions.

Company information

We have received high praise from semiconductor manufacturers for our development of IC sockets for semiconductor evaluation. Currently, we flexibly and swiftly respond to the diverse needs of automotive electronics, image sensors, and semiconductor manufacturers, providing a comprehensive proposal of materials necessary for development, prototyping, evaluation, production, and shipping. We also boldly challenge ourselves in the development of new products, supporting the rapidly changing electronics industry. Additionally, as of October 1, 2006, Yamato Glass has changed its company name to Yamato Material Co., Ltd. to aim for greater possibilities, with the goal of further business expansion alongside the penetration of an accurate corporate brand image.