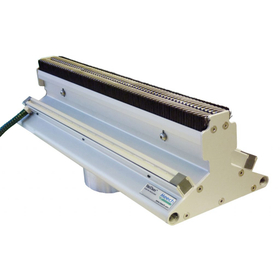

A servo press ultrasonic welding machine capable of achieving stable welding is now available, featuring tool-free stack replacement!

After 11 years since the release of the ultrasonic servo welding machine in 2010, Duquesne's ultrasonic servo welding machine has been reborn! The servo motor has been upgraded, maintaining the maximum load while increasing the speed of the up-and-down stroke, thereby shortening the cycle time. In addition to the patented melt detection function, speed profile function, and double hold control function that can also be used with previous models, it is equipped with more advanced welding control features such as load detection control and load increase rate control. The front of the press unit features a status screen that displays the condition of the device, allowing operators to grasp the current situation at a glance by showing various information. The smart stack quick change system enables tool-free stack replacement, achieving significant time savings during changeovers.

Inquire About This Product

basic information

- The melting detection function (world patent) achieves an increase in welding strength and a reduction in variation. - The stability of welding quality (process capability index) has dramatically improved due to high-precision servo pressure control. - By not using compressed air, manufacturing costs are reduced, and a clean environment is maintained. - The speed profile function allows for up to 10 levels of speed switching during welding, enabling appropriate pressure conditions tailored to the resin's melting state, resulting in stronger welds. - The amplitude during welding can be set arbitrarily in up to 3 stages, allowing for amplitude conditions that match the characteristics of the application. - The adoption of the Smart Stack Quick Change System allows for stack replacement in a short time without the need for tools. - By embedding cables inside the column (support), the area around the device is kept tidy, and the risk of cable disconnection is reduced. - The dedicated control software "iQ-Explorer III" can be installed and used on your PC (Windows) and supports Japanese display.

Price range

Delivery Time

Applications/Examples of results

- Medical components - Automotive components - Electrical/Electronic components - Consumer products - Packaging

Detailed information

-

The status display screen on the front of the press unit shows the current status of the device and various messages.

-

The adoption of a tool-free smart stack quick change system has significantly reduced the time required for stack changes.

Line up(17)

| Model number | overview |

|---|---|

| 1550.2Y.A2-X4N.2R | Infinity-X4, 15kHz/5000W, 200-240VAC, 4450N |

| 1536.2Y.A2-X4N.2R | Infinity-X4, 15kHz/3600W, 200-240VAC, 4450N |

| 2050.2Y.A2-X4N.2R | Infinity-X4, 20kHz/5000W, 200-240VAC, 4450N |

| 2036.2Y.A2-X3N.2R | Infinity-X3, 20kHz/3600W, 200-240VAC, 2450N |

| 2026.2Y.A2-X3N.2R | Infinity-X3, 20kHz/2600W, 200-240VAC, 2450N |

| 2012.2Y.A2-X3N.2R | Infinity-X3, 20kHz/1200W, 200-240VAC, 2450N |

| 2036.2Y.A2-X2N.2S | Infinity-X2, 20kHz/3600W, 200-240VAC, 2450N |

| 2026.2Y.A2-X2N.2S | Infinity-X2, 20kHz/2600W, 200-240VAC, 2450N |

| 2012.2Y.A2-X2N.2S | Infinity-X2, 20kHz/1200W, 200-240VAC, 2450N |

| 2036.2Y.A2-X2N.2U | Infinity-X2, 20kHz/3600W, 200-240VAC, 2450N |

| 2026.2Y.A2-X2N.2U | Infinity-X2, 20kHz/2600W, 200-240VAC, 2450N |

| 2012.2Y.A2-X2N.2U | Infinity-X2, 20kHz/1200W, 200-240VAC, 2450N |

| 3018.2Y.A2-X1N.2R | Infinity-X1, 30kHz/1800W, 200-240VAC, 660N |

| 3012.2Y.A2-X1N.2R | Infinity-X1, 30kHz/1200W, 200-240VAC, 660N |

| 3512.2Y.A2-X1N.2R | Infinity-X1, 35kHz/1200W, 200-240VAC, 660N |

| 4012.2Y.A2-X1N.2R | Infinity-X1, 40kHz/1200W, 200-240VAC, 660N |

| 5006.2Y.A2-X1N.2R | Infinity-X1, 50kHz/600W, 200-240VAC, 660N |

catalog(2)

Download All CatalogsCompany information

Dukane Japan is the Japanese subsidiary of Dukane IAS LLC, headquartered in St. Charles, Illinois, USA. It supports various plastic welding processes with its unique advanced technologies, including ultrasonic servo welders utilizing servo control technology, ultrasonic probe systems that can be controlled and monitored from external PLCs via Ethernet IP connection or CC-Link connection, vibration welders capable of high-precision welding with high mechanical rigidity, and the Servo Weld Plus (Dual Servo) spin welder that performs rotation and pressure control via servo. Additionally, with the motto "One World, One Dukane," it offers comprehensive support in countries and regions outside Japan through a worldwide network that spans major industrial nations. This allows for the relocation of equipment purchased in Japan to overseas locations for local service, as well as the maintenance of equipment relocated from abroad in Japan.