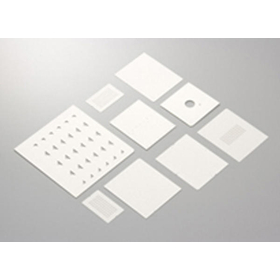

We have added "high-purity alumina (99.6%) substrates" to our lineup and prepared standard samples (100x100x0.2).

■Alumina Ceramic Substrates Born from Our Unique Production System■ In recent years, the electronics industry, which is accelerating the pace of evolution, has developed tiny chip components that can now fit on the tip of a finger, advancing the information society. Among these, chip resistors are essential basic electronic components for constructing electronic circuits. Our alumina ceramics use high-purity alumina raw materials that excel in electrical and thermal properties, achieving excellent dimensional accuracy and divisibility through advanced processing technology. For other alumina ceramic products as well, we use high-purity alumina raw materials tailored to their applications, maintaining stable quality and excellent characteristics while producing under a strict quality control system.

Inquire About This Product

basic information

Alumina Ceramic Substrates: KA6 Series, KA9 Series Widely recognized as "alumina ceramics," our general-purpose grade 'KA6 Series (alumina purity = 96%~97%)' is commonly used. We also offer a high-purity grade 'KA9 Series (alumina purity = 99.6%)' in our lineup, preparing to meet a wide range of applications. You can choose from our lineup according to your specific needs. Features of our product lineup: - Capable of manufacturing with high precision in thickness and dimensions - High-precision through-hole forming and split groove (slit, snap) forming are possible - A rich variety of thickness options allows for consistent consultation from prototyping to mass production (KA6 Series)

Price range

Delivery Time

Applications/Examples of results

Applications / Examples of Achievements - Characteristics that can be applied to a wide range of uses among numerous ceramics - Due to its widespread use in the world, there is relatively abundant usage history and knowledge in various fields Our alumina ceramic substrates are utilized in many electronic devices and are widely used in electronic equipment, communication devices, automotive applications, and industrial equipment.

Detailed information

-

"Alumina ceramics," widely recognized as a ceramic substrate, is commonly used in our general-purpose grade 'KA6 series (alumina purity = 96%~97%).' We are preparing to offer a high-purity grade 'KA9 series (alumina purity = 99.6%)' in our lineup to accommodate a wide range of applications.

-

Through an in-house integrated process, we achieve molding processing of green sheets that meets customer specifications by using mold press processing. In particular, by utilizing precision mold press processing technology, "fine and micro processing" becomes possible. These sheet processing methods can accommodate processing specifications such as "non-standard shapes," "through holes," and "split slits" on sintered ceramic substrates by applying press processing using high-precision molds. In the case of chip resistors, we have a production record for the minimum chip size of 0603 (0.6mm x 0.3mm). For split slits, we have achieved mass production with a minimum depth of 0.08mm. By applying advanced slit management, we can provide "split chip sizes of 50% of the board thickness." We also support three-dimensional mold press processing, achieving molding of "3D pillar chips" with dimensions below 0.5mm.

-

By forming a split groove for division through mold forming, it becomes possible to process individual pieces. The minimum size can be as small as 0.6mm × 0.3mm.

-

By using laser processing, it becomes possible to achieve high dimensional precision in shape processing. Fine hole processing (minimum Φ0.05mm) is possible.

-

Laminated processing allows for the thickening of ceramic substrates. The photo above shows a 2mm thick ceramic substrate created by stacking two 1mm thick green sheets that were formed and coated, followed by a firing process.

catalog(2)

Download All CatalogsCompany information

Kyoritsu Elex Co., Ltd. is a specialized manufacturer of ceramic substrates for electronic circuits that has been in business for over half a century since its establishment. Our products are widely used as key components in the internal electronic parts of various products, including mobile phones, computers, LCD televisions, automotive control circuits, and more. Based on the know-how we have cultivated over the years, we aim to continue supplying products that meet the needs of the times to the ever-evolving electronics industry, and we aspire to contribute to the creation of a richer society.

![Improving thermal conductivity of alumina substrates with printed circuit technology [For mounting power devices!]](https://image.mono.ipros.com/public/product/image/aef/2000837251/IPROS92922931863825394276.png?w=280&h=280)