Even complex and diverse products that are difficult to inspect with rule-based methods can be inspected with Roxy AI!

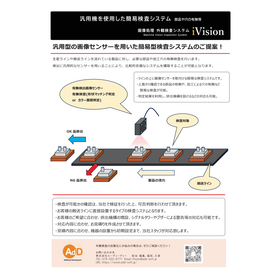

Here is an introduction to a case of foreign matter contamination inspection in seafood products. Although the product was thought to be very difficult, we were able to complete the learning and verification in just over an hour. This reaffirmed the high accuracy and rapid learning capabilities of Roxy AI. ■ For products that were deemed impossible to automate inspections! It is challenging to establish judgment rules for agricultural products and seafood that have no identical shapes, leading to a resignation from automated inspections or even a lack of consideration for them. With AI, the judgment methods can be learned autonomously, greatly expanding the range of applicability. ■ One solution for both defect detection and foreign matter contamination detection Not only can it accurately extract individuals that are unsuitable as products due to missing heads, but it can also detect shrimp mixed in with small fish with high precision. This allows for a simpler inspection system, thereby reducing total costs. ■ Upgrade existing inspection systems It comes standard with interfaces that can connect with PLCs, various cameras, and rule-based inspection products. It can be integrated with Keyence's XG, XG-X, and VJ series as standard. This allows for the addition of AI inspections without wasting existing inspection systems.

Inquire About This Product

basic information

For more details, please request a catalog or feel free to contact us.

Price information

Negotiable

Delivery Time

※Negotiable

Applications/Examples of results

[Other Examples] - Inspection of foreign matter contamination that is difficult to detect visually - Inspection of very small defects in automotive parts - Inspection of products where the boundary between normal and defective is ambiguous - Inspection of medical supplies and many more

catalog(7)

Download All CatalogsNews about this product(1)

Company information

In small and medium-sized enterprises that support a large part of the manufacturing industry, it is difficult to secure engineers who are knowledgeable about AI. Additionally, in environments that are forced to produce small quantities of a wide variety of products, it is not realistic to outsource AI development each time. What is needed now is "AI that can be effectively utilized on-site." "Being able to effectively utilize it on-site" does not simply refer to the ability to easily create AI or to have a user-friendly interface. There are many AI inspection products that focus on finding highly accurate AI through repeated parameter tuning, but we adopt the approach of injecting the know-how of inspectors into AI to create high-quality AI. Roxy AI will cultivate high-quality AI by improving the quality of training data. To enhance the quality of training data, we incorporate unique features such as proprietary visualization technology and tactile feedback. Roxy is an AI inspection product that is closely aligned with the on-site needs, contributing to the improvement of productivity in the manufacturing industry.

![[Video Available] That's why it's high precision! Roxy AI](https://image.mono.ipros.com/public/product/image/35d/2000657223/IPROS07460542255951714006.png?w=280&h=280)

![[Video Available] There is a reason for the high accuracy of 'Roxy AI'!](https://image.mono.ipros.com/public/product/image/684/2000727146/IPROS62517446238953945665.jpeg?w=280&h=280)

![[Video Available] "Roxy AI" cleans data and improves accuracy!](https://image.mono.ipros.com/public/product/image/4de/2000727155/IPROS35845975524027918276.jpeg?w=280&h=280)

![[Video Available] 'Roxy AI' Makes Detecting Foreign Objects in Dried Sardines This Easy!](https://image.mono.ipros.com/public/product/image/a97/2000727166/IPROS34550180444939971435.jpeg?w=280&h=280)