The working height is 895mm! A molding machine specifically designed for liquid silicone proposed by a rubber injection molding machine manufacturer.

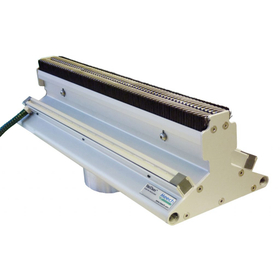

We would like to introduce our "Liquid Silicone Dedicated Injection Molding Machine." The clamping force is 1472 kN (150 tons) and the daylight is 900 mm. The platen size is 710 mm × 680 mm, and the ejector force is 26.8 kN (2.7 tons). Please feel free to contact us if you have any inquiries. 【Specifications (partial)】 ■ Clamping force: 1472 kN (150 tons) ■ Daylight: 900 mm ■ Clamping stroke: 650 mm ■ Platen size: 710 mm × 680 mm *For more details, please refer to the related links or feel free to contact us.

Inquire About This Product

basic information

【Other Specifications】 ■ Heating Plate Heater (Metacon Replacement) - Upper Mold: 750W x 2 units, 500W x 4 units - Lower Mold: 750W x 2 units, V500W x 4 units ■ Ejector: 26.8kN (2.7 tons) ■ Injection Volume: 108cm³ ■ Injection Pressure: 220MPa ■ Extruder: φ30mm ■ Hydraulic System: 15kW Inverter Pump Control ■ Working Height: 895mm ■ Machine Size: Width 1318mm x Depth 4557.3mm x Height 2632mm *For more details, please refer to the related links or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the related links or feel free to contact us.

Company information

Sanyou Industrial Co., Ltd. has prioritized "integrated machinery and electronics" as its foremost challenge since its establishment. In a wide range of fields including rubber injection molding machines, factory automation, environmental conservation equipment, energy business, and aerospace equipment industry, we have consistently introduced advanced technologies and cutting-edge equipment, leading innovation and offering high-performance products to the market, earning a reputation for our high technical capabilities. Furthermore, our company has been working on building a quality assurance system based on international standards through company-wide projects, and in 1998, we were able to obtain ISO 9001 certification. Taking this opportunity, we aim to further enhance reliability and continuously introduce new technologies to advance product development that stays ahead of the times. We are also committed to thoroughly improving productivity and reducing costs, dedicating our full efforts as a company to create products and a company that will further satisfy our customers.