[Technical Data] Reduced Temperature Variation! High-Performance Water-Cooled Microchannel Heat Sink

If you're looking to enhance the performance of heat management components while also achieving miniaturization, weight reduction, and energy efficiency, this is a must-see!

Our company designs, manufactures, and sells microchannel heat sinks. We can suppress the temperature rise to 40°C for a heat generation of 260W/cm². The microchannel flow paths are arranged across the entire cooling surface, ensuring that the refrigerant is evenly distributed throughout all flow paths. Fresh refrigerant uniformly spreads within the plane, reducing temperature variations, improving cooling efficiency, and achieving low thermal resistance. 【Features】 ■ Suppresses temperature rise to 40°C for a heat generation of 260W/cm² ■ Microchannel flow paths are arranged across the entire cooling surface ■ Internal structure ensures even distribution of refrigerant across all flow paths ■ Reduces refrigerant volume ■ No need to significantly lower the refrigerant inlet temperature *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

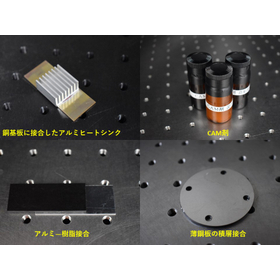

【Lineup】 ■M4040 Heat Sink ■M2020 Heat Sink ■Custom design according to desired shape and thermal specifications. Both double-sided cooling and slim design are possible.

Price range

Delivery Time

Applications/Examples of results

【Applications】 ■ Cooling of supercomputer CPUs ■ Cooling of lasers/LEDs/Peltier elements ■ Cooling and temperature control of automotive semiconductors (ADAS systems, power semiconductors) ■ Cooling, temperature control, evaporation, and condensation of other fluids

catalog(1)

Download All CatalogsCompany information

High-performance, compact, lightweight, and thermal management components provided through fine diffusion bonding technology, contributing to energy savings. Not just bonding, but also one-stop shopping for structural design, thermal fluid design, and more. We accommodate everything from prototype single items to mass production. Capable of fine three-dimensional structures, surface bonding, laminated bonding of thin plates, and bonding of dissimilar materials. Suitable for mass production of prototypes for 3D laminated structures and 3D printers. Applicable to hollow components, fine three-dimensional structures, high-pressure and high-efficiency heat exchangers with fine flow paths, high-efficiency heat sinks, reactors, mixers, and more. Extensive experience and proven results in providing solutions across various industries, including automotive, medical devices, semiconductor manufacturing equipment, food equipment, special inspection devices, power, and electrical/electronic components. For more details, please contact us.

![[Explanatory Material] What is a Water-Cooled Microchannel Heat Sink? *Free Distribution](https://image.mono.ipros.com/public/product/image/b17/2000726009/IPROS74746189462372996053.png?w=280&h=280)