Eddyfi ECTANE3 Electromagnetic Application Non-Destructive Testing Device

ECTANE3

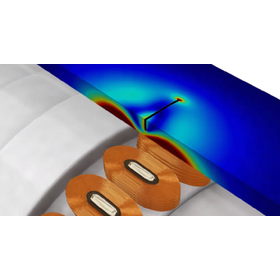

New model debut: Innovation in heat exchanger small tube inspection using the latest Remote Field Array (RFA) and AI-ECT!

Ectane has over 1,000 delivery records spanning more than 10 years. The third-generation unit supports the tenth technology, Remote Field Array (RFA) technology, enabling advanced inspection of heat exchanger tubes. Unmatched Power and Flexibility Ectane is the world standard in electromagnetic application inspection of tubes and surfaces. This equipment offers a wide frequency range from 5 Hz to 10 MHz, 8 channel inputs, and up to 32 time slots, accommodating a broad range of applications. The modular design of Ectane 3 comes in 11 models, selectable to meet inspection needs, and is available in three different array configurations: 64 elements, 128 elements, and 256 elements, supporting 10 different inspection techniques. Wide Range of Applications Performs 10 types of inspection techniques: ECT, ECA, TECA, NFT, NFA, RFT, RFA, MFL, MFLA, IRIS. RFA, the Emergence of Advanced Inspection Technology The Remote Field Array (RFA) using a patent-pending low-frequency multiplexer is an inspection technology that only Ectane 3 can provide. It delivers high-resolution C-scan imaging for carbon steel tube heat exchanger inspections.

Inquire About This Product

Related Videos

basic information

【Basic Features】 • Dimensions (H × W × D): 279.6 × 254.0 × 158.8 mm • Weight: 6.8 kg (with battery) • Enclosure Cooling: Sealed, fanless • Protection Rating: IP65 • Frequency: 5Hz - 10MHz • Array Connector: 160 pins • ECT (Extended)/RFA Connector: 41 pins • RFT/NFT/MFL Connector: 19 pins • ECT (Bobbin) Connector: 4 pins • I/O Connector: 18 pins • IRIS Connector: BNC Flexibility for Integration into Inspection Systems Ectane3 is an ideal system for automated inspection using ECA probes with robotic arms or crawlers. Multiple analog inputs and outputs are available to facilitate communication with PLCs. • Five TTL inputs for controlling remote data acquisition • 3-axis encoder input • Three relays to output system status • Real-time alarms and data streaming • Data acquisition software compatible with SDK

Price range

Delivery Time

Applications/Examples of results

Heat exchanger tube inspection (ECT, ECA, NFT, NFA, RFT, RFA, IRIS) Supports the majority of inspection methods, including the latest remote field array for magnetic tubes. Artificial intelligence-based tube inspection using Magnifi 5.x Through a process utilizing a patent-pending AI neural network, Magnifi enables the automatic detection of tube sheets, support plates, defects, etc., in heat exchanger ECT inspections. It aims to support higher quality data collection. Wide range of surface inspection capabilities • Detection and sizing of cracks in carbon steel welds (TECA) • Corrosion assessment of aluminum and stainless steel tank floors • Detection of stress corrosion cracking in base materials and high-precision depth evaluation • Surface inspection of various plant piping • Inspection of aircraft components • Surface inspection of railway axles

Detailed information

-

RFA probe

-

Probot Pusher

-

I-Flex Surface Array Probe

-

SPYNE Large Surface Array Probe

Line up(11)

| Model number | overview |

|---|---|

| ECTANE3-E | |

| ECTANE3-I | |

| ECTANE3-ERNM | |

| ECTANE3-ERNMI | |

| ECTANE3-E64RNM | |

| ECTANE3-E64RNMI | |

| ECTANE3-E128RNM | |

| ECTANE3-E128RNMI | |

| ECTANE3-E64 | |

| ECTANE3-E128 | |

| ECTANE3-E256 |

catalog(4)

Download All CatalogsNews about this product(4)

Company information

Eddyfi Technologies contributes to improving productivity in manufacturing, various plants, and inspection service providers by offering the world's leading non-destructive testing (NDT) technologies, as well as promoting a safe society and environmental protection. The company focuses on providing advanced phased array ultrasound and eddy current array technologies, along with various ultrasonic and electromagnetic application technologies, including inspection equipment, sensors, software, and robots for key industries such as aerospace, energy, mining, power, and transportation. Eddyfi Technologies has over 650 employees across 13 centers of excellence (technology hubs) and sales offices worldwide, with NDT technology experts stationed at all locations.

![Dial gauge and camera-equipped image processing tool presetter [Easy to operate]](https://image.mono.ipros.com/public/product/image/fb0/2001055026/IPROS46579019489030899320.jpeg?w=280&h=280)