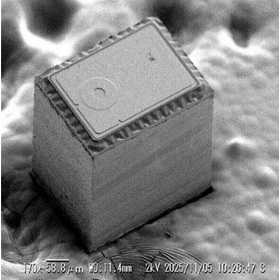

Visual inspection of materials with no gloss (low reflectivity)! Introducing how to illuminate them.

Visual inspection using light has become mainstream, but it cannot be said that all inspection objects can be inspected using the same manual. The effect of illumination differs between glossy (high reflectivity) materials and non-glossy (low reflectivity) materials. In other words, slight adjustments are necessary depending on the material of the object being inspected. This time, I have summarized visual inspection for non-glossy (low reflectivity) materials. [Contents] ■ Illumination surface when illuminated from the front ■ Methods to prevent light reflections *Detailed content of the column can be viewed through the related links. For more information, please feel free to contact us.

Inquire About This Product

basic information

*You can view the detailed content of the column through the related link. For more information, please feel free to contact us.*

Price range

Delivery Time

Applications/Examples of results

*You can view the detailed content of the column through the related link. For more information, please feel free to contact us.*

Company information

The lighting environment is an important factor that affects the productivity of various inspection processes. "The shape of the light source makes it difficult to distinguish scratches and color unevenness." "Glare makes it easy for workers' eyes to become fatigued." By addressing these lighting-related issues, significant improvements in productivity and work efficiency can be achieved. The challenges in inspection lighting cannot be understood without going to the site.

![[Column] What is the Appropriate Illumination for Inspections? - Solving Challenges in Inspection Sites -](https://image.mono.ipros.com/public/product/image/260/2000844847/IPROS78975244746484303856.png?w=280&h=280)

![[Column] Can factory lighting help reduce fatigue accumulation?](https://image.mono.ipros.com/public/product/image/805/2000844855/IPROS81585362544495921769.png?w=280&h=280)

![[Inspection Case] Visual inspection of resin molded products manufactured overseas. Reduction of manufacturing losses.](https://image.mono.ipros.com/public/product/image/505/2000722021/IPROS28503039874702977962.png?w=280&h=280)