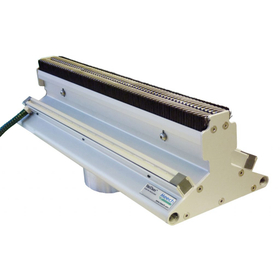

Ultrasonic welding machine P220/P215 series equipped with a variety of features.

P220/P215

The P220 and P215 series, which encompass features to achieve stable ultrasonic welding, offer a wide range of options to accommodate various products.

The new basic model series P220/P215 from Duquesne offers options equipped with features such as time control, energy control, peak power control, as well as distance control functions for welding distance and welding end position control. The load trigger mechanism has also been upgraded to a specification that detects actual load using high-end load cells, and even the standard model has transitioned from the traditional analog volume adjustment to a digital method using numerical input from the oscillator, improving reproducibility during step changes. The data output function, which was not supported in the previous i220 series, is now available through the use of the iQ-Explorer3 software. Additionally, when used in automatic machines, there is an iQLinQ communication function option that allows for complete control and monitoring from the device's PLC. Previously, external PLCs could only switch the welding conditions saved in the oscillator, but with iQLinQ, it is now possible to rewrite each parameter, significantly enhancing the compatibility between automatic machines and ultrasonic welding machines. Models are available for all frequencies of 15/20/30/35/40 kHz, allowing customers to choose the specifications that best suit their products.

Inquire About This Product

basic information

- Two-stage pressure control that allows switching between welding and hold (cooling) pressure - Five types of welding control available: time/energy/peak power/welding distance (collapse)/position (absolute) (only for "05" model) - New load trigger function with numerical input from the oscillator (standard feature) - Actual load trigger function that sets the trigger load using actual load measured by a load cell (optional) - Patent technology output trigger function - Stable ultrasonic oscillation with the industry's fastest sampling at 0.5ms - Line regulation to eliminate amplitude variation due to input voltage fluctuations - Load regulation that prevents amplitude reduction even under high load conditions - Compatible with iQ-Explorer 3 software (optional) - Optical sensor type two-hand push start switch that reduces operator burden - The 15kHz and 20kHz/5000W models are compatible with the P215 model equipped with a Φ76mm cylinder - The 20kHz is compatible with the P220 model equipped with a Φ63mm cylinder - The 30/35/40kHz models are compatible with the P220 model equipped with a Φ38mm cylinder

Price range

Delivery Time

Applications/Examples of results

- Medical components - Automotive components - Electrical/Electronic components - Consumer products - Packaging

Line up(16)

| Model number | overview |

|---|---|

| 1550.2H.C0-04.AR | 15kHz/5000W, Time/Energy/Peak Power Control |

| 1550.2H.C0-05.AR | 15kHz/5000W, Time/Energy/Peak Power/Welding Distance/Position Control |

| 2050.2H.C0-04.AR | 20kHz/5000W, Time/Energy/Peak Power Control |

| 2050.2H.C0-05.AR | 20kHz/5000W, Time/Energy/Peak Power/Welding Distance/Position Control |

| 2012.2H.C0-04.MS | 20kHz/1200W, Time/Energy/Peak Power Control |

| 2012.2H.C0-05.MS | 20kHz/1200W, Time/Energy/Peak Power/Welding Distance/Position Control |

| 2026.2H.C0-04.MS | 20kHz/2600W, Time/Energy/Peak Power Control |

| 2026.2H.C0-05.MS | 20kHz/2600W, Time/Energy/Peak Power/Welding Distance/Position Control |

| 2036.2H.C0-04.MS | 20kHz/3600W, Time/Energy/Peak Power Control |

| 2036.2HC0-05.MS | 20kHz/3600W, Time/Energy/Peak Power/Welding Distance/Position Control |

| 3018.2H.C0-04.KS | 30kHz/1800W, Time/Energy/Peak Power Control |

| 3018.2H.C0-05.KS | 30kHz/1800W, Time/Energy/Peak Power/Welding Distance/Position Control |

| 3512.2H.C0-04.KS | 35kHz/1200W, Time/Energy/Peak Power Control |

| 3512.2H.C0-05.KS | 35kHz/1200W, Time/Energy/Peak Power/Welding Distance/Position Control |

| 4012.2H.C0-04.KS | 40kHz/1200W, Time/Energy/Peak Power Control |

| 4012.2H.C0-05.KS | 40kHz/1200W, Time/Energy/Peak Power/Welding Distance/Position Control |

catalog(2)

Download All CatalogsCompany information

Dukane Japan is the Japanese subsidiary of Dukane IAS LLC, headquartered in St. Charles, Illinois, USA. It supports various plastic welding processes with its unique advanced technologies, including ultrasonic servo welders utilizing servo control technology, ultrasonic probe systems that can be controlled and monitored from external PLCs via Ethernet IP connection or CC-Link connection, vibration welders capable of high-precision welding with high mechanical rigidity, and the Servo Weld Plus (Dual Servo) spin welder that performs rotation and pressure control via servo. Additionally, with the motto "One World, One Dukane," it offers comprehensive support in countries and regions outside Japan through a worldwide network that spans major industrial nations. This allows for the relocation of equipment purchased in Japan to overseas locations for local service, as well as the maintenance of equipment relocated from abroad in Japan.