Contributing to the carbon neutrality of industrial furnaces: Case study of high-frequency induction furnace introduction.

Realization of energy savings and CO2 reduction through the transition from cupola furnaces to electric furnaces/high-frequency induction furnaces.

Case study of the introduction of electric furnaces (high-frequency induction furnaces) and furnace operation monitoring systems. The challenges prior to implementation included building a manufacturing system aimed at decarbonization and green growth strategies, as well as achieving energy conservation and CO2 reduction. The transition from a cupola, which uses coke as a heat source, to an electric furnace, which uses electricity as a heat source, has led to reduced environmental impact, improved quality and safety, and stabilized the supply of maintenance parts.

Inquire About This Product

basic information

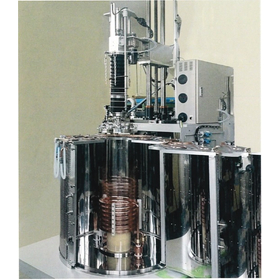

Product Information: High-Frequency Induction Furnace Realizing Energy Savings for Electric Furnaces The high-frequency induction furnace F-MELT100G, which integrates energy-saving and power supply technologies into a high-efficiency induction furnace, contributes to the energy savings of electric furnaces and the carbon neutrality of industrial furnaces. Additionally, utilizing IoT-driven data analysis technology, the induction furnace becomes user-friendly, providing smartly analyzed data feedback to the equipment, enabling optimization of operations, cost reduction, and contributing to improved production efficiency.

Applications/Examples of results

■Energy Saving and CO2 Reduction Case Study (Akasaki Iron Works Co., Ltd.) [Customer Feedback] "The fact that they hold the top market share in the industry and were able to introduce the latest electric furnace was impressive. It was also good that the supply of maintenance parts is stable. By switching to an electric furnace, we can reduce CO2 emissions and improve quality, which leads to a decrease in environmental impact and enhanced safety." *Excerpt from customer interview in the introduction case study video [Products and Systems Introduced] High-Frequency Induction Furnace (F-MELT100G) Furnace Monitoring System [Challenges Before Introduction] Building a manufacturing system towards decarbonization and green growth strategy; achieving energy savings and CO2 reduction [Benefits from Introduction] Reduction of environmental impact; improvement in quality and safety; stabilization of maintenance parts supply

catalog(10)

Download All Catalogs

Improving production efficiency and avoiding production stoppage risks with the introduction of IGBT power supply.

Visualization of operations in the new factory using the furnace monitoring system.

Survey on Awareness of IoT and Data Utilization in Foundries

Survey on Carbon Neutrality in Foundries

Survey on Energy-Saving Measures in Foundries

Survey on Awareness of Energy-Saving Measures in Factories and Plants

High-frequency induction furnace F-MELT100G that realizes energy saving for electric furnaces.

Examples of energy saving and CO2 reduction through the transition to electric high-frequency induction furnaces.

Increased the batch size of the dissolution furnace and introduced a high-power IGBT power supply.

Current Status and Challenges of Decarbonization Efforts in Foundries 2025

Company information

Providing solutions for various plants and factories such as food, chemicals, oil and gas pipelines, paper and pulp, and cleaning facilities. Our measurement and control systems have over 40 years of history since the launch of the first distributed control system in 1975. Based on our track record, we propose systems and solutions to support the latest technologies, IoT utilization, and the development of smart factories. - Steam generation heat pumps / waste heat utilization / visualization of thermal energy - Clamp-on steam flow meters / flow meters / flow sensors / thermal balance analysis - Industrial furnaces / electric furnaces / high-frequency induction furnaces / IGBT power supplies - Gas analyzers / gas measurement devices / gas analysis sensors - Predictive maintenance / anomaly detection maintenance / preventive maintenance / maintenance and prevention systems / smart security - Smart factory - MES / DCS / SCADA / edge controllers - EMS / energy management systems / visualization of energy - Smart glasses / remote work support systems - Multivariate analysis / MSPC - Engineering tools