We will produce a secondary vulcanization furnace for silicone rubber tailored to molded products.

At Hakkou Electric, we have been manufacturing various rubber and silicone rubber vulcanization furnaces based on the know-how from our own production of silicone rubber heaters. During the vulcanization of silicone rubber, siloxane molecules generated can condense when the temperature drops during exhaust, leading to various issues such as clogging of flow paths and overheating of heaters. Hakkou Electric has been conducting research on how to address these adhering byproducts, aiming to provide safe and easy-to-maintain vulcanization furnaces.

Inquire About This Product

basic information

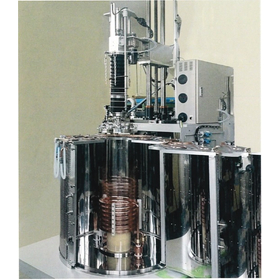

Batch furnace (a vulcanization furnace without work movement or transport mechanism) Continuous furnace (a vulcanization furnace that automates processing by moving the work) The continuous furnace has various achievements, including belt conveyors, roller conveyors, chain transport, tray transport using double chains, and three-dimensional tray transport. We can meet various customer requests, such as tact processing using infrared sensors, touch panel operation via sequencers, and traceability through temperature logging.

Price range

Delivery Time

Applications/Examples of results

Secondary curing of silicone rubber products Curing of rubber Drying of screen-printed materials

Company information

In a world that constantly changes, the Yahiko Group has been working hard under the slogan "We exist for society." As a result, we have received high praise in fields such as residential and industrial heat sources, disposable medical products, medical devices, assembly machinery for the electronics and electrical industries, electronic typesetting systems, and computer-related systems.