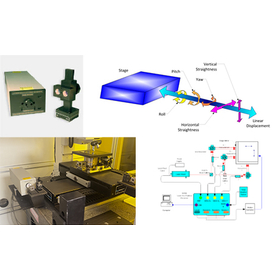

NIST/ISO compliant laser interferometer (displacement meter) capable of easy and precise measurement of up to 6 axes simultaneously.

In this laser interferometer system, a combination of optical modules allows for simultaneous high-precision measurement of up to 6 degrees of freedom (X, Y, Z, pitch, yaw, roll) from a single axis. The installation and alignment of the system are very simple. Additionally, it is possible to further improve accuracy by correcting the wavelength of the measurement laser using optional environmental sensors and refractometers. With over 5,000 installations, it has become the de facto standard worldwide in fields such as semiconductor manufacturing equipment like wafer and FPD steppers, CNC machines, and displacement measurement in motion systems, as well as research institutions in various countries.

Inquire About This Product

basic information

Linear Positioning Measurement Range: ±5 m, Accuracy: 0.0005% (without wavelength correction), Resolution: 10 nm Yawing Measurement Range: ±3600 arc seconds: ±5° (angle correction), Accuracy: ±0.2% (relative to displayed value), Resolution: 0.1 arc seconds Pitching Measurement Range: ±3600 arc seconds: ±5° (angle correction), Accuracy: ±0.2% (relative to displayed value), Resolution: 0.1 arc seconds Rolling Measurement Range: ±3000 arc seconds: ±3° (angle correction), Accuracy: ±0.3% (relative to displayed value), Resolution: 0.5 arc seconds Levelness Measurement Range: ±500µm, Accuracy: ±2µm + 0.5µm/m, Resolution: 0.5µm Verticality Measurement Range: ±500µm, Accuracy: ±2µm + 0.5µm/m, Resolution: 0.5µm Vibration Measurement Range: ±500µm (simultaneously on X, Y, Z axes), Accuracy: ±2µm + 0.5µm/m, Resolution: 0.5µm Data Smoothing Processing Can be set between 10-75 seconds (depending on application)

Price range

Delivery Time

Applications/Examples of results

As optical components for interferometers, we have over 5,000 delivery records in fields such as semiconductor manufacturing equipment like wafer and FPD steppers, CNC machines in the machine tool sector, displacement measurement in motion systems, and various national standard research institutions, making us the de facto standard worldwide. We offer a wide range of optical systems for various applications, including linear interferometers, plane mirror interferometers, differential interferometers, single beam interferometers, angle interferometers, and straightness interferometers. We also provide vacuum-compatible interferometers, beam benders, and beam splitters.

Detailed information

-

About the stabilization of the two-frequency longitudinal mode Zeeman laser and the measurement principle: By applying a longitudinal magnetic field to a He-Ne laser, the Zeeman effect is induced, allowing the laser to oscillate in a two-frequency longitudinal mode, achieving high precision and reproducibility in interference measurements. Additionally, the two-frequency beam causes a Doppler shift due to the movement of the measurement mirror within the interferometer, enabling the determination of the object's velocity from the difference between the detection signal and the reference signal. By calculating the product with time using a processor, position data can be accurately measured in real-time. Furthermore, this Zeeman laser interferometer utilizes a heterodyne method that separates the reference light and measurement light at 2 MHz, allowing for very accurate measurements; when the target is stationary, the frequency is exactly 2 MHz, and it changes when the target moves. The advantages of this Zeeman laser interferometer are: 1. The frequency of the laser reference is accurate, and 2. It operates at 2 MHz due to heterodyne technology, which can eliminate low-frequency noise.

-

As optical components for interferometers, we offer a variety of optical systems for various applications, including linear interferometers, plane mirror interferometers, differential interferometers, single beam interferometers, angle interferometers, and straightness interferometers. We also provide vacuum-compatible interferometers, beam benders, and beam splitters.

-

Abundant measurement accessories The XY laser position sensor makes measurements of rotation, vibration, and deviation more accurate by detecting slight changes in the surface of objects and movements in the Z direction, regardless of reflectivity or color. The level meter measures the tilt of an object from the horizontal plane with a sensitivity of 0.1 seconds of angle. Additionally, there is a weather station for laser wavelength correction that measures temperature, relative humidity, and atmospheric pressure in real-time, as well as a refractometer. Calibration tools for optional CNC machining can help maintain or improve machining accuracy.

catalog(1)

Download All CatalogsCompany information

■ Manufacturing and sales of laser equipment and its application devices and parts, as well as import and export operations ■ Manufacturing and sales of electrical and electronic equipment and its application devices and parts, as well as import and export operations ■ Sales of optical equipment and its application devices and parts, as well as import and export operations ■ Manufacturing and sales of medical, physical, and measuring instruments and their application devices and parts, as well as import and export operations ■ Manufacturing and sales of adhesives, adhesive tapes, adhesive sheets, and their equipment and devices, as well as import and export operations ■ All operations incidental to the above items