To ensure equipment maintenance and the reliability and lifespan of electronic devices, it is effective to investigate corrosive substances in the operating environment and take countermeasures.

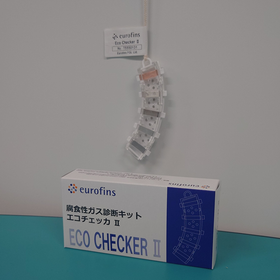

The usage environment of electronic devices varies. The impact of corrosion caused by various environmental factors tends to increase. Corrosive substances generated from hot springs, volcanoes, waste, and rivers can lead to corrosion of electronic components, printed circuit board wiring, connector contacts, and switch contacts in electrical equipment, potentially causing serious troubles. Therefore, investigating corrosive substances in the usage environment is effective for equipment maintenance and ensuring the reliability and lifespan of electronic devices. Our original corrosion environment diagnostic kit, "Eco Checker II," offers a low-cost and simple diagnostic procedure. It allows for easy investigations such as screening for corrosive substances through multi-point surveys. ■ Free Webinar Announcement! ■ We will introduce methods for diagnosing corrosion environments centered around our original corrosion environment diagnostic kit, Eco Checker II. 【Date】 July 22, 2025, 10:00–10:30 【Venue】 Online (Teams) This is recommended for those who are concerned that atmospheric conditions in the operating environment may lead to electronic device failures, or who wish to reduce failure risks in harsh environments such as hot springs or wastewater treatment plants. If you wish to participate, please contact us!

Inquire About This Product

basic information

Product size, weight: approximately 3×9 cm, about 10 g Simultaneously diagnoses three types: - Sulfur dioxide gas (SO2) - Hydrogen sulfide gas (H2S) - Chlorine-based gases (Cl2, HCl, NaCl, etc.)

Price information

For more details, please contact us.

Delivery Time

Applications/Examples of results

In addition to concerns about the corrosion of electronic equipment, it can be utilized for various purposes such as environmental management of public facilities and workplaces, and investigation of unpleasant odors in daily life. - Data centers, machine rooms, computer rooms - Offices, base stations, communication equipment rooms - Manufacturing plants for electrical and electronic equipment, clean rooms - Food storage facilities, freezing rooms, processing plants - Storage warehouses for parts and products - General office spaces - Rivers, waste disposal sites, sewage treatment plants - Museums, art galleries - Paper mills, rubber factories - Instrumentation equipment, power facilities

Line up(1)

| Model number | overview |

|---|---|

| Eco Checker Quantitative Analysis | The Eco Checker II is a kit that allows customers to easily diagnose corrosive environments themselves, and we also offer analysis of the degree of corrosion. By conducting this analysis, we can clearly quantify the effects of corrosive gases, enabling more accurate continuous monitoring of the atmospheric environment and improvements in corrosion resistance. |

catalog(5)

Download All CatalogsNews about this product(1)

Company information

Eurofins FQL Co., Ltd. has its origins in the analysis division of Fujitsu Laboratories Ltd. and the quality assurance department of Fujitsu Ltd. It has long engaged in activities aimed at improving product quality, not only in material analysis, reliability evaluation, safety assessment, and failure analysis, but also in supplier quality management and manufacturing plant audits. Additionally, it contributes to solving challenges faced by organizations responsible for quality through the development and educational support of personnel involved in quality, as well as the construction and improvement of quality management, product chemical substance management systems, and software development processes. ■ Reliability Evaluation and Environmental Testing Various reliability evaluations, safety verification of secondary batteries and power supplies, etc., including smoke and fire hazards. Evaluation of special environments such as weather resistance and gas corrosion. ■ Failure Analysis Failure analysis of electronic components and devices, confirmation of characteristics related to materials, and detailed analysis of defects. ■ Support for Building and Improving Quality-Related Systems and Processes To achieve QCD (Quality, Cost, Delivery) goals, we support the improvement of development processes using models such as CMMI and Automotive SPICE. ■ Quality-Related Education Customized educational programs tailored to specific challenges, such as "I want to revitalize the organization," "I want to cultivate a quality mindset," and "I want to provide quality education for new employees."