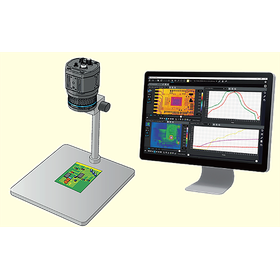

Thermographic inspection system: Temperature measurement perspective during substrate development.

Introducing the applications of the thermography inspection system!

The thermography inspection system can be used for "temperature measurement vision during substrate development." As an authorized dealer of TELEDYNE FLIR products, we offer a wide range of high-performance "thermal cameras." We also provide a "thermography controller" that can inspect temperature changes on production lines that are not visible to the naked eye. 【Fixed Thermal Camera Features】 ■ Wi-Fi communication (compatible models: A50/A70/A400/A500/A700) ■ Equipped with a visible camera (compatible models: A50/A70/A400/A500/A700) ■ Macro mode (compatible models: A400/A500/A700) *For more details, please refer to the related links or feel free to contact us.

Inquire About This Product

basic information

【Thermographic Controller Effects】 ■ Abnormal Inspection: Detects temperatures that differ from normal and issues alerts before problems occur. ■ Quality Judgment: Sets the temperature conditions for good products and identifies temperatures outside the range as defective for sorting. ■ Continuous Temperature Data Collection: Measures temperature changes at multiple points, records them, and utilizes them for traceability in cases of quality defects. *For more details, please refer to the related links or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the related links or feel free to contact us.

Company information

We are a technology trading company that creates new value in response to the times, from infrastructure to the latest technologies.