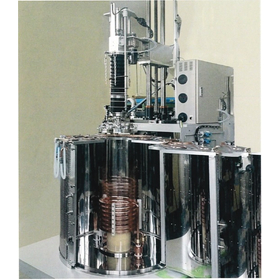

Linking a continuous batch furnace with FA (automation equipment for labor-saving).

This device is designed to automate the process of loading large workpieces into a batch furnace, in conjunction with automatic machinery, with the aim of reducing labor. The device shutter opens and closes automatically. The loading and unloading of workpieces do not require operator intervention. Features: Pitch conveyance and linkage with automatic machinery Device Overview Standard Specifications ■ Temperature Range: Room temperature to approximately 130°C ■ External Dimensions: W2550mm × L1685mm × H2730mm ■ Internal Dimensions: W880mm × D1080mm × H1030mm ■ Effective Dimensions: W500mm × D500mm × H400mm ■ Number of Circuits: 3 circuits ■ Heating Method: Hot air circulation type *Dimensions and other specifications can be modified according to customer requirements. The device can be customized to meet customer specifications. Applications It can be used for various applications such as paint drying, adhesive curing, varnish drying, and resin curing.

Inquire About This Product

basic information

Standard Machine Specifications ■ Temperature Range: Room temperature to approximately 130°C ■ External Dimensions: W2550mm × L1685mm × H2730mm ■ Internal Dimensions: W880mm × D1080mm × H1030mm ■ Effective Dimensions: W500mm × D500mm × H400mm ■ Number of Circuits: 3 circuits ■ Heating Method: Hot air circulation type *Dimensions and other specifications can be changed according to customer requirements. Customizable equipment to meet customer specifications.

Price range

P6

Delivery Time

※Standard machine approximately 4 to 5 months (FA part to be discussed).

Applications/Examples of results

Can be used for various applications such as paint drying, adhesive curing, varnish drying, and resin curing.

Company information

Since its founding, GLOBAL Co., Ltd. has consistently specialized in manufacturing custom electric furnaces tailored to client specifications. With a proven track record across diverse industries, we have recently focused on developing automated heat treatment systems integrated with AGVs (Automated Guided Vehicles) and robots. Our hot-air circulation dryers automate the entire process—from transport and loading to cooling—enhancing safety, labor efficiency, and traceability. Internally, we are equipped to perform thermal-fluid simulations using 3D modeling to analyze temperature distribution and cooling behavior within the furnace. This enables precise heating design and energy savings, supporting the development of high-quality, highly reliable systems. Simulation results are fed back into design, contributing to stable real-world performance. Our in-house factory and cleanroom facilities allow us to handle everything from design and manufacturing to inspection, including support for precision and electronic components. This integrated setup enables flexible, high-quality production with short lead times—from prototyping to mass production. At exhibitions, we showcase simulation models, live equipment footage, and real-world case studies to present concrete solutions to on-site challenges. We invite you to experience the next generation of heat treatment technology firsthand. If you'd like a shorter version (e.g. under 500 words), or a version optimized for pitch decks or international partners, I’d be happy to help tailor it further.