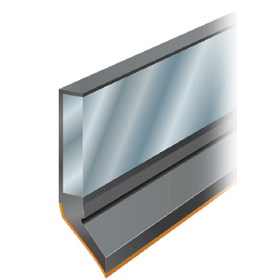

Can be used in environments where rubber oil seals are not suitable! High-performance resin lip seals that require no molds and save space!

This is a seal for rotational motion made from high-performance resin through integrated machining. An O-ring is used as the seal for the outer peripheral fixed part, ensuring that there is no concern about scratching during attachment and detachment, even with soft metals or resin housing materials. We can accommodate special shapes according to customer specifications. Seal Tech offers lip seals that solve your problems! 【Features】 ■ Design can be tailored to the dimensions of the seals currently in use ■ No molds are required as they are produced through machining, allowing for small lots during prototyping ■ Easily attachable and detachable without compromising sealing performance, even with soft metal or resin hardware ■ A wide variety of lip materials and O-ring materials are available ★ Our company has accumulated know-how regarding "hardware conditions and compatibility" through many years of experience. This is also very important for selecting the appropriate seal design (performance, lifespan, etc.). Please feel free to consult us about your usage examples (operating conditions) and requests.

Inquire About This Product

basic information

The body, machined from PTFE material, is combined with an O-ring on its outer circumference. We will suggest the materials for the body and O-ring according to the application and usage conditions. Additionally, very important for the use of this product are the hardware conditions (surface roughness, hardness, compatibility due to differences in conditions, etc.). Our company has accumulated know-how from over 35 years of experience in selling spring-loaded seals and lip seals. We will respond to your challenging applications, including requests to replace existing seals or extend maintenance periods.

Price range

Delivery Time

Applications/Examples of results

■ CMP device ■ Various pumps ■ Rotary joint ■ Tool holder, spin coater ■ Stirrer

catalog(1)

Download All CatalogsCompany information

We, Seal Tech Co., Ltd., entered into a sales agency agreement with FURON Corporation in the United States in June 1987 and began domestic sales of their SPRING ENERGIZED SEAL. Today, there is a growing demand for improved working environments, efficiency, and safety across all industrial sectors. However, even in this technologically advanced era, issues caused by fluid leakage persist, and we feel that the demands are increasing. Through the sale of fluid control equipment, our company has developed as a technical trading company that addresses such troubles and technical challenges, responding to the increasingly sophisticated and diverse needs, and contributing to Japanese manufacturing. To gain even greater trust and assurance from our customers, we obtained ISO 9001 certification on April 24, 2011, and are committed to continuous improvement and maintenance through the thorough establishment and operation of a "Quality Management System." Moving forward, we will continue to adopt a customer-oriented approach and strive to respond accurately and swiftly to our customers' needs through the development of products and technologies. We sincerely ask for your continued support and patronage.

![[Case Study] Replacement of Oil Seal (Lip Seal)](https://image.mono.ipros.com/public/product/image/259/2000695334/IPROS9489383045678345266.jpg?w=280&h=280)

![[For efficient water drainage] 100% water-draining air nozzle](https://image.mono.ipros.com/public/product/image/00f/2001469742/IPROS9319730289540870960.png?w=280&h=280)