"I am good at what I am not good at with gas" Fluidized Bed Heat Treatment Furnace FLUID BATH

A heat treatment furnace that seems to be processing as if in a liquid, using a fluidized sand treatment method.

This is a method that further develops our fluidized bed technology, allowing various treatment gases to be introduced as fluidizing gases at higher temperatures, resulting in uniform heating throughout the sand and enabling heating in deep hole shapes as if it were liquid. Additionally, the introduced treatment gases are delivered close to the product surface along with the sand, where they undergo reactions such as decomposition. This allows for more uniform treatment even for shapes that are easily affected by gas flow. Furthermore, it also has the advantage of a cleaning effect as a fluidized bed, enabling the combined process of cleaning and treatment.

Inquire About This Product

basic information

【Fluidized Bed Heat Treatment Furnace】 - Layer sizes: φ350×H650, φ500×H650, φ650×H750 (catalog models) * Custom-made options are also available beyond the above. - Auxiliary equipment: Cooling tank (oil cooling, water cooling) - Operating temperature: 200℃ to 1200℃ … varies by model This machine does not have a physical unit available for demonstration or testing. ===== Please contact us for more details=====

Price information

In addition to general-purpose models, we also offer products in sizes tailored to your requests, so please feel free to contact us.

Delivery Time

※It varies depending on your requested specifications, so please contact us.

Applications/Examples of results

- Mold polishing + nitriding treatment … Treatment for complex shapes, such as deep holes, which are difficult to process with gas treatment. - Same as above (TD) … Forming a high-sliding characteristic treatment layer on the re-surface of the nitriding layer. - Removal of residual sand from aluminum castings … Cleaning of sand that is stubbornly adhered to the product and difficult to remove with air or other means. - Cleaning of coating treatment equipment … Cleaning of fixtures and ancillary equipment used for processes like vapor deposition coating. *There are various other application examples as well.

Detailed information

-

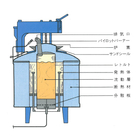

This is a simple furnace structure diagram.

Line up(6)

| Model number | overview |

|---|---|

| FT-300 | Maximum operating temperature: 300℃ |

| FT-600 | Maximum operating temperature: 600℃ |

| FT-650 | Maximum operating temperature: 650℃ |

| FT-1000 | Maximum operating temperature: 1000℃ |

| FT-1100 | Maximum operating temperature: 1100℃ |

| FT-1200 | Maximum operating temperature: 1200℃ |

catalog(3)

Download All CatalogsCompany information

The pursuit of cutting-edge technology is, at the same time, an effort to minimize the burden on the natural environment to the utmost. Our technology plays a vital role in the manufacturing process to enable coexistence with the creatures that inhabit the beautiful oceans, rivers, and mountains of this Earth. With a commitment to ecology, we, as pioneers in thermal science, are promoting the development of high-value-added products that pursue specialties such as technologies for improving mechanical functions aimed at developing pollution-free vehicles. Furthermore, through proactive business development, including multifaceted management expansion and entry into new fields of competitive product technology, we are working to stabilize our management foundation. Additionally, through technological partnerships with top leaders who possess world-class technology, we are accumulating a new sense of the era and advanced technological capabilities, earning strong trust from users around the world.

![[Equipment Introduction] Heat Treatment Furnace](https://image.mono.ipros.com/public/product/image/025/2000663909/IPROS55700757093251356107.png?w=280&h=280)

![Single End Radiant Tube Burner [TRF Burner]](https://image.mono.ipros.com/public/product/image/c08/2000793597/IPROS40624651388633756578.png?w=280&h=280)