Room Temperature Wafer Bonding Device BOND MEISTER【Semiconductor Manufacturing】

Room Temperature Wafer Bonding Device BOND MEISTER

A room temperature wafer bonding device that opens new horizons in the bonding process. Supporting device development with high reliability, bonding quality, and bonding support services!

Joining is performed by activating the surface of the joining materials with an ion beam in a vacuum. ■Application in MEMS wafer-level packaging - Packaging can be done at the wafer level before dicing, simplifying subsequent processes. - Since no heating is involved, thermal distortion is eliminated even for fine structures. - Increased productivity as there is no need for heating and cooling time. - Ideal for the development of stacked high-integration MEMS. ■Application to other high-functionality devices - Capable of joining a wide range of materials such as metals, quartz, sapphire, and oxide single crystals. - High yield is achievable due to the absence of thermal distortion. - Dissimilar materials can also be joined at room temperature, enabling previously impossible joints and enhancing design flexibility for devices. A lineup of equipment that maximizes the benefits of the room temperature joining process (all-in-one setup including alignment equipment, wafer transport robots, and bonding mechanisms). For more details, please contact us or download the 'catalog' for confirmation.

Inquire About This Product

basic information

Joining is performed by activating the surface of the joining materials with an ion beam in a vacuum. ■Application in MEMS wafer-level packaging - Packaging can be done at the wafer level before dicing, simplifying subsequent processes. - Since no heating is involved, thermal distortion is eliminated even for fine structures. - Increased productivity as there is no need for heating and cooling time. - Ideal for the development of stacked high-integration MEMS. ■Application to other high-functionality devices - Capable of joining a wide range of materials, including metals, quartz, sapphire, and oxide single crystals. - High yield is achievable due to the absence of thermal distortion. - Dissimilar materials can also be joined at room temperature, enabling previously impossible joins and enhancing design flexibility for devices. A lineup of equipment that maximizes the benefits of the room temperature joining process (all-in-one equipped with alignment devices, wafer transport robots, pressure bonding mechanisms, etc.) For more details, please contact us or download the 'catalog' for confirmation.

Price range

Delivery Time

Applications/Examples of results

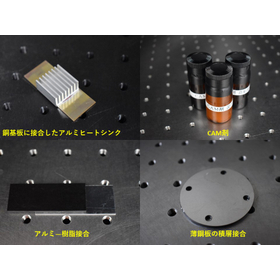

We have a track record of bonding with various materials such as silicon-based, oxide-based materials like quartz glass, compound semiconductors, and metal materials. Please feel free to contact us for more details.

catalog(1)

Download All CatalogsCompany information

Since our founding in 1939, we have been creating machine tools and cutting tools that are essential to the manufacturing industry. Even as society changes rapidly, we support people's rich lives through "monozukuri" (the art of making things). We constantly pursue new technologies, challenge unknown territories, and continue to provide production systems that are truly needed in the world. This is our commitment.

![[Leveling Correction] Leveling correction of concrete floors "Teratec Method"](https://image.mono.ipros.com/public/product/image/d08/1267539002/IPROS70063422645318547243.jpeg?w=280&h=280)

![[Case Study] Construction Example of High-Temperature Facilities in Factories Using High-Performance Heat Insulation Sheets](https://image.mono.ipros.com/public/product/image/962/2000579577/IPROS04218491152233419232.jpeg?w=280&h=280)