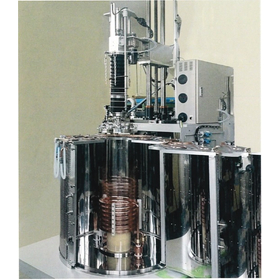

Special furnace [Dew point control high-temperature atmosphere furnace]

Dew Point Control High-Temperature Atmosphere Furnace

High-temperature atmosphere furnace with dew point control handled by Marusho Electric Co.

The dew point controlled high-temperature atmosphere furnace can be used for various research and development and small-scale production of ceramics, electronic components, etc., under advanced atmosphere control such as reducing atmosphere and dew point controlled atmosphere, and can also accommodate special specifications according to user requests. ■□■Features■□■ - Internal dimensions: W150mm×D150mm×H180mm to W300mm×D300mm×H300mm - Operating temperature: Normal use 1600℃, maximum 1700℃ - Vacuum replacement type - Equipped with a dew point control system (maximum 80℃ for wetters) ■For more details, please contact us.

Inquire About This Product

basic information

The dew point controlled high-temperature atmosphere furnace can be used for various research and development and small-scale production of ceramics, electronic components, etc., under advanced atmosphere control such as reducing atmosphere and dew point controlled atmosphere, and can also accommodate special specifications based on user requests. ■□■Features■□■ - Furnace dimensions: W150mm×D150mm×H180mm to W300mm×D300mm×H300mm - Operating temperature: Normal use 1600℃, maximum 1700℃ - Vacuum replacement type - Equipped with a dew point control system (maximum wet bulb temperature 80℃) ■For more details, please contact us.

Price information

-

Delivery Time

Applications/Examples of results

Marusho Electric's technology caters to a wide range of industries, including food baking and preservation, printing and film curing, continuous annealing of wire, CVD applications, high-precision atmospheric processing for superconductors, glass melting for optical lenses, pressing and annealing, rare heaters for glass float, preform furnaces for synthetic quartz, brazing, bright annealing, debinding and sintering for ceramics and sintered metals, ash melting furnaces, main combustion test furnaces, single crystal pulling furnaces, titanium high-purity equipment, gas heating devices, and more. With heater design technology, insulation design technology, vacuum technology, gas atmosphere control, dew point and oxygen concentration technology, and various heating experiences, we handle everything from small experimental devices to production equipment across a wide range of fields.

catalog(1)

Download All CatalogsCompany information

Marusho Electric has been engaged in various heating devices by leveraging heater design technology, control technology, and a consistent system. In the cutting-edge technology fields we handle, such as FPD-related materials, electronic components, semiconductors, glass, fine ceramics, and CNT, there is a demand for highly advanced and precise heating and thermal processing technologies. For many years, we have utilized our advanced technical capabilities in these fields down to the finest details, and by consolidating them, we have made significant contributions to technological innovation and product development. What we take pride in is our technical capabilities that can meet various demands and our in-house integrated production system that supports them. Our exceptional technical capabilities and production system are highly regarded by many Japanese companies making strides in the world, and we are recognized as an important partner in their research, development, and production. Our motto is to continue making the utmost efforts in pursuit of "new dimensions" and "new creations." We will continue to challenge the new possibilities of "electric heating" with our wide-ranging experience, achievements, and insatiable curiosity, growing together with our customers who use our equipment.

![Special furnace [single crystal pulling device]](https://image.mono.ipros.com/public/product/image/6c5/68420017/IPROS_15688610209793421000.jpg?w=280&h=280)

![Special Furnace [High-Temperature Behavior Observation Furnace]](https://image.mono.ipros.com/public/product/image/ab4/68420018/IPROS_14883789128515674000.jpg?w=280&h=280)

![Special Furnace [Vertical Multi-Atmosphere Furnace]](https://image.mono.ipros.com/public/product/image/2f6/68420020/IPROS_14114209340060324000.jpg?w=280&h=280)

![Special Furnace [Atmosphere Press Furnace]](https://image.mono.ipros.com/public/product/image/db3/68420022/IPROS_17215877793930359000.jpg?w=280&h=280)

![Special furnace [Small carbon nanofiber manufacturing device]](https://image.mono.ipros.com/public/product/image/ed2/68420025/IPROS_10736125073149917000.jpg?w=280&h=280)

![[Case Study] Induction Heating Device](https://image.mono.ipros.com/public/product/image/fd2/2001465015/IPROS2166796305397651041.png?w=280&h=280)