Environmentally friendly technology utilizing water pressure! Achieving energy savings and low noise through the electrification of functional devices! Capable of simultaneous flexible processing and mold bulging processing.

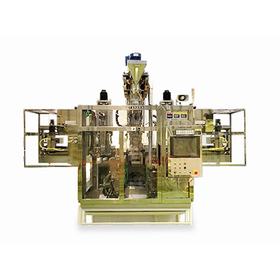

The hydraulic forming device is a fully automatic machine that utilizes environmentally friendly water pressure technology, ensuring high safety. The HDL-CHB-40 small hydroforming and flex forming machine has eliminated the need for large clamping force by adopting a special mechanical locking mechanism. Furthermore, this device is a dual-purpose machine capable of both flex processing and mold bulging, achieving high precision in molded products as well as energy savings and compactness.

We will exhibit this product at MF-TOKYO 2019. We sincerely look forward to your visit.

■ Features

- No use of air

- Compatible with both flex forming and hydroforming

- Clamping mechanism with a special mold locking mechanism

- Easier loading and unloading of workpieces with the adoption of a 6-axis multi-joint robot, etc.

【Exhibition Overview】

■ Dates: July 31 (Wed) - August 3 (Sat), 2019, 9:00 AM - 5:00 PM (until 4:00 PM on the last day)

■ Venue: Tokyo Big Sight, West Halls 1 & 2 and South Halls 1 & 2

- Booth number: W2-21

■ Admission fee: 1,000 yen (free for pre-registered attendees and those with invitation tickets)

*For more details, please contact us or download the catalog.

![[Currently Available for Catch-Up Viewing] Green Molding <2024>](https://image.mono.ipros.com/public/product/image/673/2001535015/IPROS11932604664553502956.png?w=280&h=280)

![100% reduction in air consumption! No need for large clamping force [Hydraulic forming machine]](https://image.mono.ipros.com/public/product/image/98e/287001/IPROS84472413781296495989.jpeg?w=280&h=280)