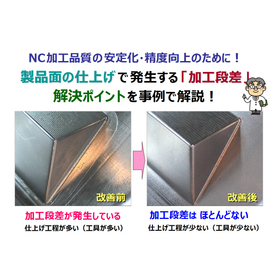

To improve the quality and precision of NC machining! What are the key points for resolving machining step differences?

What are the key points for solving the 'processing step' that is likely to occur in product finishing? We are currently offering materials such as "Case Studies on Troubleshooting in Mold Processing"!

In finishing processes, if there are many leftover steps and a large number of tools are used, thermal displacement of each axis and the main spindle of the machine can easily cause "machining steps" on the finished surface. Therefore, to reduce or eliminate machining steps, it is essential to minimize the types and number of tools used during the finishing process. 【Five Important Points in Finishing Processes】 ◇ Tool Selection 1. Use tools with good cutting performance and edge accuracy (no variation in R accuracy or outer diameter). 2. Use tools with low deflection and high rigidity (use a pencil neck when the protrusion is long). 3. Use tools with coatings suitable for the work material (especially for soft steel). ◇ Machining Methods and Cutting Conditions 1. Ensure that roughing before finishing does not leave any material in corners or recesses. 2. In semi-finishing, process the entire area to a uniform finishing allowance (do not leave large bumps). 3. In finishing, avoid high-speed rotation to minimize the expansion and contraction of the machine spindle. 4. Use cutting fluid to improve chip removal and lubrication of the cutting edge. For more details, please refer to the PDF document. If you have any questions, please feel free to contact us.

- Company:オーエスジー株式会社グループ

- Price:Other