Company brochure, product development introduction video, completed!

The company profile and product development introduction video have been released.

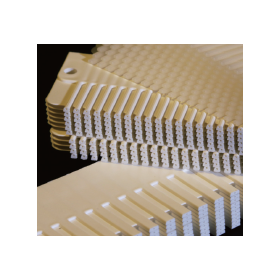

This is the official channel operated by Sekisui Techno Molding, a part of the Sekisui Chemical Group. https://www.youtube.com/@sekisui-techno-molding-c Company information and product development introduction videos have been released. We will be posting detailed videos of new products that are useful to society. Please subscribe to the channel and wait for the upload of new videos! Links Sekisui Techno Molding Homepage https://sekisui-techno-molding.jp/ Plabarrier Homepage https://sekisui-techno-molding-products.jp/plabarrier Special Site for Newly Developed Plastic Molding Products https://www.sekisui-techno-new-product.co.jp/index/ Special Site for Heat Dissipation EMC Molding Products https://sekisui-techno-new-product.co.jp Special Site for Fine Molding Products https://sekisui-techno-new-product.co.jp/index/sp02

- Company:積水テクノ成型 新事業開発部

- Price:Other