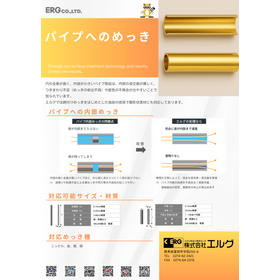

Coating of the inner surface of the pipe, fine (ultra-fine) parts.

Avoiding the occurrence of non-plating in the central part of the inner surface of the pipe with our unique manufacturing technology!

Plating on pipes, fine (ultra-fine) parts, and springs is part of our surface treatment technology. Plating tends to be difficult to adhere to the central part of the inner surface of pipes, leading to areas without plating or uneven plating. Our company avoids these issues through unique manufacturing techniques, including mesh application. Additionally, plating is possible even for fine (ultra-fine) products, fine springs, and products with a high number of turns. *For more details, please refer to the PDF materials or feel free to contact us.

- Company:ERG

- Price:Other