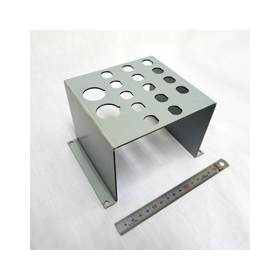

SECC t1.6 / Laser cutting processing + Press processing

Shortest half-day estimate / SECC t1.6 / Laser cutting processing + Press processing

After laser processing, bending processing at 4 locations. Our company offers comprehensive sheet metal processing and laser processing for materials such as iron, stainless steel, and aluminum. For details on company information, processing, and material content, please refer to the catalog available for download in the section below. Additionally, our official website contains even more detailed information. We can handle cutting processing for prototype and development parts, from metals to resins! If you have any questions, please feel free to contact us.

![[Kitashin Industry] Introduction of our industry-leading comprehensive facilities](https://image.mono.ipros.com/public/product/image/618/2000238495/IPROS7932777997008661964.JPG?w=280&h=280)