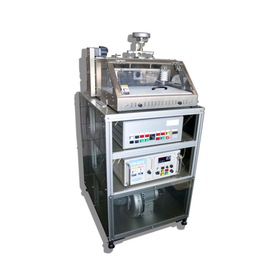

Barrel-type plasma treatment device PB series

Utilizing isotropic plasma, ideal for cleaning and modifying fine patterns and the inner surfaces of tube shapes!

The barrel-type plasma treatment device "PB Series" utilizes isotropic vacuum plasma for the removal of organic materials (Ashing), removal of oils (Cleaning), etching of silicon compounds (SiO2, SiN), and improvement of wettability, all without the use of solutions (Wet). It achieves a good environmental performance (clean working environment, no waste liquid) and low running costs. Treatment progresses from all directions, demonstrating the effects of nano-level processing, cleaning, and modification regardless of the shape of the target object. 【Device Features】 ■ Free processing that does not select sample shapes (cylindrical treatment chamber / isotropic plasma) ■ Diverse processes: Ashing (cleaning), Etching, surface modification, etc. ■ All parts are compatible with clean room standards (can be used as semiconductor manufacturing equipment) ■ Cost-effective, small footprint design ■ Safety specifications suitable for use as a mass production device For more details, please contact us or download the catalog.

- 企業:電子技研

- 価格:Other

![Software PBX Implementation Case Study Presentation! [Sharle Co., Ltd.]](https://image.mono.ipros.com/public/product/image/882/2001487943/IPROS62756494753443857166.jpeg?w=280&h=280)

![Commercial Food Waste Processor Sink Pia [GJ-30]](https://image.mono.ipros.com/public/product/image/3d7/2000248052/IPROS16270783902866969613.jpeg?w=280&h=280)

![Commercial food waste disposer Sink Pia [GJ-50]](https://image.mono.ipros.com/public/product/image/3c2/2000248059/IPROS76019920770813740059.jpeg?w=280&h=280)

![Commercial Food Waste Processor Sink Pia [GJ-100]](https://image.mono.ipros.com/public/product/image/d6a/2000248062/IPROS27237182758934938125.jpeg?w=280&h=280)

![Commercial Food Waste Processor Sink Pia [GK-6400]](https://image.mono.ipros.com/public/product/image/9a7/2000470615/IPROS12772905198172401315.JPG?w=280&h=280)

![[Case Study of Food Waste Disposal Machine] Sanhouse Food Co., Ltd.](https://image.mono.ipros.com/public/product/image/8ff/2001514787/IPROS15234242621443433778.jpg?w=280&h=280)