Hot plate unit

Precision temperature control, cleanroom manufacturing. Heaters supporting next-generation semiconductors.

This is a heater with a structure that sandwiches a mica heater between aluminum plates. It is manufactured in a Class 10,000 cleanroom, achieving a uniform temperature distribution. It is mainly used in the wafer resist coating and drying processes within semiconductor manufacturing equipment. 【Material Specifications】 ■ Material: AL ■ Material: SUS ■ Material: SIC *For more details, please download the PDF or feel free to contact us.

- Company:Sakae Corporation Onishi Factory

- Price:Other

![[Case Study] Hot Plate Unit](https://image.mono.ipros.com/public/product/image/397/2001539448/IPROS1036532763470990955.png?w=280&h=280)

![[Case Study] Reagent Heating Unit Components](https://image.mono.ipros.com/public/product/image/f33/2001539454/IPROS9560010181344633770.png?w=280&h=280)

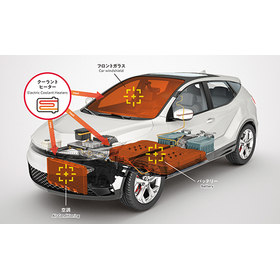

![[Examples of Thermo Heater Applications] Prevention of Freezing and Solidification, Temperature Management](https://image.mono.ipros.com/public/product/image/f7f/2001516920/IPROS12511315167230369434.jpg?w=280&h=280)