[Example] New heat-resistant alloy (Inconel type, gun drill, lathe)

This is a case study of processing a new type of heat-resistant alloy.

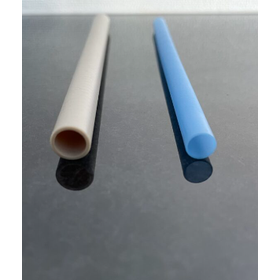

This is a processing example of a new type of heat-resistant alloy (if Inconel 718, a nickel-based alloy, can be processed, it is a material that can be processed). 【Case Details】 Outer diameter: φ25.4 (supplied material is φ27) Inner diameter: φ21.4 Total length: 500mm (supplied material is 502) *If you are having trouble with the accuracy and quality of deep hole machining, please contact Fuji Shin Seisakusho. *Please view the "Manufacturing Case Collection" PDF data from the download section.

- Company:不二新製作所

- Price:Other

![[Example] New heat-resistant alloy (Inconel type, gun drill, lathe)](https://image.mono.ipros.com/public/product/image/fd2/2000261033/IPROS8557936871769579026.jpg?w=280&h=280)

![[Example] FC250 (Gun drill, BTA processing)](https://image.mono.ipros.com/public/product/image/b5d/2000261037/IPROS7233993998096889178.jpg?w=280&h=280)

![[Example] HPM7 (Gun drilling process, multiple holes)](https://image.mono.ipros.com/public/product/image/da8/2000261039/IPROS8546441959933470223.jpg?w=280&h=280)

![[Processing Example] Long-Length Trepanning Processing](https://image.mono.ipros.com/public/product/image/6ef/2000661534/IPROS20468755723563942253.jpeg?w=280&h=280)

![[Processing Example] Counter BTA Processing of Spindle Products](https://image.mono.ipros.com/public/product/image/7a9/2000662359/IPROS90077744135621780907.jpeg?w=280&h=280)