Fluororesin-related services

Consolidating the know-how cultivated in special steel, mold manufacturing, and mold design into the now-in-demand fluororesin sector for new business development.

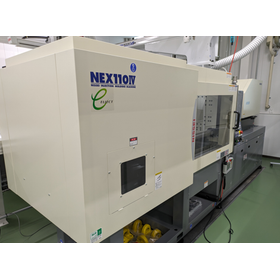

Our company is engaged in the fluororesin-related business. Leveraging our expertise in high-strength mold manufacturing, we propose solutions for extending lifespan and adjusting molding. We have established high-precision equipment and environments. 【Features】 ■ Dedicated injection molding machines for fluororesins and high-performance inspection equipment are permanently installed. ■ Comprehensive management from design and manufacturing of molds and tools compatible with difficult-to-mold resins like PFA to trial injection. ■ Proposals for molds and parts with special corrosion-resistant welded coatings. ■ Contributing to various fields such as semiconductors and medical applications. *For more details, please refer to the PDF materials or feel free to contact us.

- Company:南海モルディ株式会社(旧:南海鋼材株式会社)

- Price:Other