Technical Data: Non-destructive Testing Technology for Automotive Parts Using Ultrasonic Testing Method

Non-destructive testing technology for automotive parts using ultrasonic testing methods.

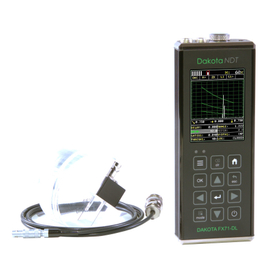

[Technical Information] This is an introduction to non-destructive testing technology using ultrasonic testing for automotive parts. ■□■Content of the Document■□■ Ultrasonic testing technology is applied in quality inspection across various industries among non-destructive testing methods. Particularly in the automotive industry, it has a long history of application and has greatly contributed to ensuring safety in parts made from lightweight materials aimed at improving fuel efficiency in recent years. Ultrasonic testing equipment is easier to handle and smaller in scale compared to X-ray testing equipment, making it relatively suitable for inspecting the internal quality of mass-produced automotive parts. Recently, with the combination of image processing technology, evaluation methods have diversified not only to determine the presence or absence of "defects" but also to identify the characteristics of "defects" and assess defective areas based on area ratio. ⇒ For more details, you can download the catalog and read further.

- Company:KJTD

- Price:Other

![[Information] Regular Inspection Methods for Ultrasonic Testing Equipment](https://image.mono.ipros.com/public/product/image/331/2001255471/IPROS14714266543820699431.png?w=280&h=280)