1~30 item / All 30 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Inquiry Form1~30 item / All 30 items

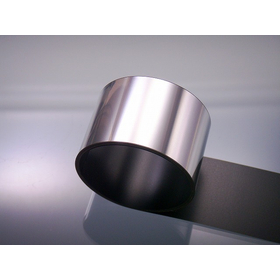

Due to the increased hardness from quenching and tempering, it can be used for applications requiring high hardness, such as springs, various cutting tools, and blades, without heat treatment. Among polished special steels, SK material (carbon tool steel) is widely used in quenching steel strips for its workability, hardenability, and cost. Although the quenching process itself is outsourced, we ensure the final quality guarantee from the material to the finished product.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

General Steels made under normal manufacturing conditions inevitably contain some non-metallic inclusions during its steel making process, which can often be a problem in applications where high reliability is required. MB-1, M1, and M2 are uniquely developed steel grades designed for knitting needles and textile machinery parts. These grades are based on SK95 and feature fewer inclusions due to adjustments in composition and the steel-making process, resulting in high cleanliness. Additionally, they aim to enhance fatigue resistance and wear resistance by incorporating elements such as Manganese, Chromium, and Molybdenum, while strictly controlling the metallic structure.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Unlike carbon steel, which hardens through heat treatment, there are few materials that harden in this way, limited to precipitation hardening systems and medium to high carbon chromium stainless steels. Martensitic stainless steel, while being a type of stainless steel, has a higher carbon content, allowing it to be hardened significantly through quenching and tempering, similar to carbon steel. Most customers who use this material after quenching apply heat treatment after forming it into various products. However, in recent years, advancements in processing equipment and techniques aimed at rationalization have made it possible to produce efficient products with minimal variation, even from extremely hard materials like hardened steel strips and quenched steel strips, through continuous pressing or cutting. As a result, heat treatment after processing the product has become complicated in terms of quality control and work management, leading to lower productivity. Consequently, there is a growing trend to switch from quenching after forming to using pre-hardened steel strips. Our company responds to the needs of customers seeking the unique properties and hardness of stainless steel, as well as high quality, by providing pre-hardened stainless steel strips. *The quenching process for SUS420J2 is primarily conducted at our Shanghai factory. For more details, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Stainless steel which has a higher Carbon content than ferritic stainless steel, and can be hardened by quenching (heat treatment) to create a martensitic structure. ■SUS420J2 is classified as a martensitic stainless steel, and although it is a stainless steel, can be hardened through quenching and tempering heat treatment. Because of its marketability, price, and usability, it is widely used in various fields. Our annealed finish makes the carbides completely spheroidized, making processing easier and has excellent hardenability. For more details, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Precipitation-hardened stainless steel is a material that possesses corrosion resistance as a stainless steel while utilizing precipitation hardening (aging) to enhance its strength. Particularly in the case of SUS631, in the annealed (solution heat-treated) state, it has a soft, metastable austenitic phase, allowing it to withstand complex processing similar to austenitic stainless steels. Additionally, by inducing precipitation hardening (heat treatment) after processing, it is possible to improve strength, achieving a combination of workability and high strength through heat treatment. Our company handles three types: SUS631 (17-7PH), SUS632J1 (15-7PH), and TOKKIN 350, and we can suggest steel types according to your applications and processing methods. *1 The general corrosion resistance ranking by system is austenitic > precipitation-hardened > ferritic. *2 Precipitation hardening refers to the artificial aging treatment performed after solution heat treatment, with the stainless steels in the 600 series and maraging steels introduced on this page being representative examples. For more details, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a steel grade in which the nickel content of SUS 304, a representative austenitic stainless steel grade, is increased and molybdenum is added to further improve corrosion resistance. SUS304 with increased nickel and molybdenum addition= SUS316: Improved corrosion resistance (pitting corrosion, stress corrosion cracking, etc.) SUS316 with higher nickel, lower carbon = SUS316L ... + Improved intergranular corrosion resistance The "L" in SUS316L stands for low carbon. Highly corrosion-resistant stainless steel is also suitable for drawing applications because of its low carbon content and high nickel content, resulting in low hardness in the annealed state and less work hardening. Note that although non-magnetic in the solution heat-treated state, it becomes weakly magnetic after strong working. This grade of steel is difficult to obtain due to its relatively small distribution volume among thin stainless steels, but we also manufacture such materials with custom specifications. Please feel free to contact us for foil with a thickness of less than 0.10 mm, special dimensions, hard finishes, short delivery times, small lots, etc. For more details, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

SUS304, a representative type of austenitic stainless steel, is non-magnetic in its solution-treated state, but it becomes magnetic (more likely to be attracted to magnets) due to martensitic transformation during cold working. Therefore, there have been challenges such as the need to keep the processing rate low to maintain non-magnetism or sacrificing strength. Non-magnetic stainless steel is a type of steel that has been adjusted so that martensite is not induced (or is less likely to be induced) during cold working, allowing it to maintain non-magnetism even after processing. We can recommend types of steel based on your usage conditions, such as processing methods and required levels of non-magnetism.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company handles five types of steel: SUS301, SUS304, SUS631, SUS632J1, and SUS420J2, allowing you to select the appropriate type based on your application, purpose, and required characteristics. We also accept orders for stainless steel foil and specifications that are not commonly available (such as thickness and heat treatment) in small lots, enabling us to provide you with the optimal condition. For more details, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

High-precision thickness materials are manufactured with precise thickness tolerances that cannot be achieved with general products manufactured based on JIS (Japanese Industrial Standards) and other standards. We produce wide range of thicknesses from 0.010 to 2.00 mm with precise thickness tolerances that cannot be manufactured by JIS or other companies. We guarantee high-precision thickness with little variation over the entire length of the hoop. The following advantages are expected by using high precision thickness materials. (1) Reduction of Post-Processing such as Polishing By reducing the post-processing required for thickness adjustment, customer can easily manage quality, shorten lead time, and reduce costs. (2) Improves Quality by Stabilizing Part Dimensions By using materials with less variation in thickness, it is possible to reduce the variation in part dimensions after stamping or drawing and improve product yields and sorting time. (3) Reduces Variations in Strength and Electrical Resistivity High-precision thickness products improve the quality of parts by reducing variations in mechanical strength, conductor resistance, etc., which are affected by material cross-sectional area. *For more details, please check the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Soft magnetic materials refer to materials that become magnetized when an external magnetic field is applied but return to their original state when the external magnetic field is removed. They are characterized by a high permeability (μ) and a low coercivity (Hc). Due to their excellent magnetic properties, such as magnetization, demagnetization, and magnetic shielding, they are used in applications like motor cores, shield cases, and digitizers. As the number of components in a single device increases, the susceptibility to high frequencies and magnetic fields has also risen, leading to a demand for materials with such properties. Furthermore, there is a growing need for miniaturization, increased strength, and corrosion resistance. In response, we are advancing the development of our unique materials that combine soft magnetic properties with these characteristics. For more details, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

High strength can be achieved through quenching, making our steel suitable for a variety of blades, including razor blades, cutter blades, and medical blades. We control the grain size using our proprietary rolling and heat treatment technologies, which enhance hardenability, workability for blade attachment, and wear resistance. In addition to high carbon steels, we also produce various types of stainless steels, allowing you to select the most suitable steel grade based on your specific applications and required properties.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

There are several types of bellows, such as welded bellows and molded bellows, depending on the manufacturing method. Bellows are used for pressure sensing and sealing because they can flexibly expand, contract, and bend while maintaining a tight seal for gases and liquids. Metal bellows have superior strength, corrosion resistance, and heat resistance, and are widely used in vacuum equipment for semiconductor manufacturing equipment, as well as in the aerospace and medical fields. Our company offers the following materials for bellows: TOKKIN 350, HC-22, HC-276, Alloy 625, SUS316L, SUS304L *For a detailed list of properties and more information, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Materials based on Ni, Co, and Ti offer superior corrosion resistance and heat resistance compared to stainless steel. The Tokkin Group supplies products that comply with the European RoHS directive under thorough quality control. 【Scope of Supply (Coils, Sheets, Foils)】 The following dimension ranges are guidelines for products manufactured by us. Since they vary by material, please contact us if you have specific specifications in mind. ■ Thickness: 0.01mm to 1.00mm ■ Width: 3mm to 300mm ■ Minimum Lot: 50kg and up ■ Shortest Delivery Time: 3 weeks [Procured Items] In addition to cold-rolled strips manufactured by us, we also flexibly accommodate orders for thick plates, wires, bars, and ultra-thin pipes from domestic and international partner companies. ■ Wire ■ Bar ■ Pipe *Please inquire about availability for fluid items. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This material, developed through our unique construction method "JIN," possesses high strength and excellent workability that cannot be achieved with conventional manufacturing methods. The yield strength (YS) and elongation (EL) balance, reaching up to 35,000 MPa%, is at a world-class level and has received the 41st "Technology Development Award" from the Japan Society of Metals. We offer two steel types, TOKKIN 350 JIN and TOKKIN 301 JIN, which can be selected based on the required property values. It is also suitable as an alternative to precipitation-hardened stainless steels such as SUS631 and SUS632J1. 【Features】 - Achieves both high strength and high ductility - Low mechanical anisotropy - High design flexibility - No heat treatment required after processing - Stable dimensional accuracy *For more details, please refer to the PDF materials and related links, or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A material with a thickness of less than 0.10 mm is generally called a foil. In recent years, components design has been moving in the direction of lighter, thinner, shorter, and smaller parts, and reducing the thickness of existing materials, is an effective way to achieve these goals. Recently, an increasing number of customers are considering switching to foil materials to reduce the height, weight, and size of components. We can produce foil materials in all the materials we manufacture, from stainless steel, low carbon steel, high carbon steel, and other steel materials to nonferrous metals such as nickel alloys, cobalt alloys, and copper alloys. Please refer to this page for stainless steel foil (SUS foil) manufacturing ranges and standards. Main features of our metal foils: (1) Electrolytic Plating is also available. Such as nickel plating and precious metal plating, which are in high demand for electronic component applications, can be processed in the hoop. Although plating itself is an outsourced process, TOKKIN can help reduce man-hours for our customers by providing comprehensive management including plating. (2) We promise high quality backed by many years of experience. TOKKIN was the first company in Japan to succeed in rolling 10 µm thickness. We guarantee quality control of surface defects, tight thickness tolerances, which are often required in electronic component applications and cannot be achieved with general materials. (3) We manufacture custom spec material in small lots. Because of made-to-order production, you can specify your preferred material, thickness, temper, and other specifications in detail. Even materials with specific specifications that are rarely available on the market can be produced in small lots by our company.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"CS Clad" is a new cladding manufacturing method that uses cold spray (low-temperature spraying) technology, which accelerates metal powder into the ultrasonic range and sprays it in a solid state to form a coating on the substrate. In addition to layering on parts, it allows for continuous coating on coils, and compared to thermal spraying, there is almost no thermal alteration or voids. Furthermore, it can form films not only from metals but also from inorganic and organic materials. 【Features】 ■ Continuous coating ■ Dense coating ■ Diverse film formation ■ Short delivery times ■ Compatible with single sheets and parts *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Various metal steel strips are pre-coated with molten solder using a roll coater method. The interface forms a diffusion bond and a chemical bond with Sn, resulting in strong adhesion. Due to the roll coater method, various specifications such as double-sided and stripes are possible. Additionally, we also accommodate molten solder processing with a thickness of 15 to 500 μm, which cannot be handled by electroplating.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is equipment for removing (degreasing) rolling oil that has adhered to the surface of the material during rolling. We own a specially designed alkaline ion water cleaning machine for hoop materials. By adopting a shower cleaning method, it is capable of sufficient oil removal even with alkaline ion water, and it is an environmentally friendly cleaning machine with low environmental impact.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Heat treatment is performed to recover the metal structure altered by cold rolling (plastic deformation) and to eliminate residual stress and strain. Depending on the material and purpose, our company utilizes bell-type furnaces for heat treatment while keeping the coils intact, as well as continuous furnaces for heat treatment after unwinding the coils. Additionally, with our long-established technology in cold rolling and heat treatment, we control the metal structure (spheroidized carbide particle size and grain size). We manage differences that are not visible in the material appearance, such as "wear resistance," "hardening ability," and "workability"! We contribute to the improvement of product quality for our customers. If you are experiencing unexplained differences in metal materials, please consult us. We also conduct cause investigations through physical inspections.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Cold rolling is a processing method that involves passing material at room temperature between rotating rolls and thinning it under upper and lower pressure, making it one of the plastic processing methods that apply significant force. Our company has achieved high-precision thickness control through our self-designed rolling machines and the incorporated AGC program for controlling the reduction position. <Advantages of Cold Rolling> Compared to hot rolling, which involves rolling heated materials, cold rolling offers better thickness accuracy, uniformity, and the ability to process to considerably thin thicknesses. Since no oxidation film is generated, a glossy surface finish can be achieved. It allows for finer and more homogeneous internal structures, contributing to stabilization after component processing. It also enables control over mechanical properties (HV, TS, YS, EL).

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We also accommodate plating on hoop materials (coils, strips) before press processing. While the plating itself is done by an external contractor, we select the optimal materials and the best external contractor based on the type, quantity, and application of the plating. Of course, we guarantee the final quality from the materials to after the plating process. The features of our plating processing are as follows: (1) We can manage everything in a centralized manner, including the materials. (2) By combining rolling and heat treatment with the plating material, we improve adhesion compared to standard plating materials. Plated rolled materials can be found here: https://www.tokkin.co.jp/materials/hybrid/jlc/ (3) With our track record of transactions with many plating manufacturers, we can select the most suitable plating manufacturer.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Resistive materials are those that have been adjusted in composition to be difficult for electricity to pass through (having a high electrical resistance value) among metals. They are mainly classified into two types: materials used for electrical resistance, such as resistors, and materials used for electric heating, such as heating elements. Electrical resistance materials limit the flow of current due to the resistance of the metal, while electric heating materials serve the purpose of generating heat when current flows through them due to the resistance of the metal. Our company manufactures various resistive materials in small lots and of high quality.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Edge processing refers to further processing of the standard slit edge to remove burrs, allowing for delivery in forms such as "mimisuri" (burr removal with a file) and "rounded edge" (where the edges are rounded). This processing enables the use of the material width and edge surface as they are for various applications. Additionally, by smoothing the edge surface, it can prevent fatigue failure from the width direction, leading to improved durability of springs.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Slitting processing refers to the process of trimming the width of metal strips. Our company accepts slitting processing orders starting from just one coil. By utilizing the technology and know-how cultivated through years of manufacturing experience, along with cutting machines suited to the material, we guarantee high slitting quality. The features of our slitting services are as follows: (1) We accommodate over 60 types of materials. (2) We promise high quality with the latest slitting equipment. (3) We meet delivery deadlines with our state-of-the-art backup system. Please consider using our services in the following situations: - I want to straighten the width of just one coil. - I want to slit multiple strips from a wide coil into narrow coils. - I would like to request slitting for special items such as plated materials or metal foils.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

TDS-1 is a "high-performance ferrite-based stainless steel" that excels in "strength," "corrosion resistance," and "soft magnetic properties." It has a high magnetic flux density and low coercivity, making it excellent in magnetization, demagnetization, and magnetic shielding properties. By applying magnetic annealing, it can be used as electromagnetic stainless steel. The main features of TDS-1 are as follows: (1) Electromagnetic Stainless Steel It can be used as electromagnetic stainless steel by applying magnetic annealing. (2) Corrosion Resistance It has superior corrosion resistance compared to SUS430. (3) Conductivity at 42Ni Level The thermal expansion coefficient of TDS-1 is about half that of 42Ni, but its conductivity is equivalent, allowing for a 50% cost reduction when switching from 42Ni. (4) Numerous Switching Achievements There are many achievements in switching from various steel types such as 42Ni, phosphor bronze, SUY, and permalloy. Our company is also capable of manufacturing foils under 0.10mm and in small lots.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

FS-1 is a unique steel grade developed by our company, which is a ferritic stainless steel that incorporates nickel (Ni) into the representative steel grade SUS430. This allows it to maintain the characteristics of ferritic stainless steel while providing a certain level of strength and corrosion resistance. It can also be used as an alternative to SUS304, which is commonly used in general environments. The main features of FS-1 are as follows: (1) Formability superior to SUS430 FS-1 has sufficient formability compared to SUS430, allowing for high-precision press processing without causing wrinkling. (2) Strength equivalent to SUS304 FS-1 can achieve full hardness with a hardness of HV330 and tensile strength of 1100 MPa (equivalent to the strength of SUS304-3/4H). (3) Minimal impact from fluctuations in nickel prices With a nickel content of only 1%, FS-1 is largely unaffected by fluctuations in nickel prices, enabling stable cost management.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Ultrafine grain steel is a material with an ultrafine structure that has crystal grains reduced to less than 1 micrometer. The refinement of crystal grains offers the following advantages: (1) Increased strength By finishing with a fine elongated grain structure through strong processing, it is possible to enhance strength. This enables the reduction of component height and thickness, leading to weight savings. (2) Improved strength-ductility balance By finishing with an equiaxed ultrafine grain structure through heat treatment after strong processing, the strength-ductility balance is improved. This allows for various processing options without sacrificing strength. (3) High fatigue properties Fatigue properties are improved compared to normal grains. This enables longer service life for components. (4) High workability - Reduction of surface roughness Due to the fine structure, surface roughness on the bending areas during metal processing can be reduced. - Stable shear surface during pressing Normal materials with larger crystal grains may experience grain detachment during fine pressing, resulting in an uneven shear surface. With ultrafine grain steel, the contour shape of the fine pressed shear surface can be stabilized.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The OVIONE coat is a material that has resin baked onto a strip of metal material for pre-coating. By simply press processing this material, it is possible to create a material that combines the properties of both metal and resin, thereby achieving requirements such as process shortening, cost reduction, and miniaturization. Our company provides high-precision coating on all types of metals. The functions that can be added with the Obiwan coat include the following: ■ Insulation ■ Prevention of solder wetting ■ Marking ■ Low friction ■ Light shielding

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

SPCC is a steel type specified in JIS G 3141 "Cold Rolled Steel Sheets and Strips," and is known as "ordinary steel" due to its ultra-low carbon content. Because of its low carbon, it is easy to process and is suitable for operations such as deep drawing in soft finish. Our company manufactures thin sheets with a thickness of t0.40mm or less and foils of t0.099mm or less, as well as annealed finishes (A) to strong rolled finishes (1B, 1D) in small lots, based on our extensive experience and technology cultivated in the production of polished special strip steel. Due to these characteristics, the applications of our materials are often found in watches, cameras, office machines, electronics, automobiles, and other special precision machinery.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Clad refers to a material that is made by bonding two or more different metals together, resulting in high-performance metal materials that possess composite properties not achievable with a single material. Since the interface between dissimilar metals in clad materials is diffusion-bonded (alloyed through elemental diffusion), the risk of delamination, as seen in plating, is significantly reduced. Additionally, it enables total cost reduction by streamlining processing steps, improving quality, and reducing lead times for customers.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration